-

Tian Dong Industrial Park, Decheng District Economic and Technological Development Zone, Dezhou City

UHMWPE vs HDPE Price–Performance: When Is “Buy Once, Cry Once” Right?

You’re weighing UHMWPE against HDPE and asking a simple question: when do I pay more upfront so I don’t pay later? Let’s cut the fluff. We’ll talk wear, friction, impact, stiffness, fabrication, and real-world scenes like base mats and ground protection. We’ll keep it plain-spoken, a bit punchy, and yes—practical for your buying decision.

Quick note: If you’re scouting Base Mats, peek our page here: UHMWPE base mats. It’ll open doors for temporary roads, cranes, events, and more.

Table of Contents

UHMWPE vs HDPE: Price–Performance Basics

Idea in one line: HDPE keeps first cost down. UHMWPE extends life where sliding, grit, and repeated hits are the daily weather.

| Factor / Metric (shop-floor lens) | HDPE (High-Density PE) | UHMWPE (Ultra-High-MW PE) | What this means for you |

|---|---|---|---|

| Coefficient of friction | Moderate (often around ~0.20) | Low (often ~0.10–0.14) | UHMWPE slides easier; parts run cooler and dont squeal. |

| Abrasion resistance | Good | Excellent | Liners, wear strips, chutes last longer with UHMWPE. |

| Impact toughness | Good | Very high | Pads, rub points, dock & crane contact zones prefer UHMWPE. |

| Stiffness / rigidity | Higher | Lower | HDPE is steadier for flat guards, covers, tanks. |

| Tensile strength (typical datasheets) | Often higher | Often lower | If you need rigid panels, HDPE behaves nicer. |

| Machining / fabrication | Easier to machine & weld | Tougher (gums a bit), still machineable | HDPE is fab-friendly; UHMWPE needs sharp tooling & patience. |

| Creep / load under long pressure | Moderate | Lower creep under impact-cycling | UHMWPE handles “hammering” loads better. |

| Water & chemical | Both low water pick-up; broad chem resistance | Same | Outdoor and wet duty are fine for both. |

| Service temperature | Similar ranges; check grade | Similar ranges; check grade | Verify grade for hot/cold extremes. |

| Typical uses | Guards, covers, tanks, panels | Wear strips, liners, guides, base mats, outrigger pads | Match the part to the failure mode, not a pretty spec. |

No exact cost numbers here, but you already know the punchline: HDPE = budget-friendly upfront; UHMWPE = fewer changeouts when the job is harsh.

“Buy Once, Cry Once” — When the Math (and the headache) Says Yes

Use UHMWPE when downtime hurts:

- Constant sliding or abrasion. Conveyor wear strips, hopper and chute liners, scraper beds. Low friction means cooler running and less stick-slip.

- Dirty, gritty, impact-heavy duty. Quarry chutes, aggregate handling, forestry gear. UHMWPE shrugs off repeated knocks.

- Access is awful. If your crew needs special lifts, shutdown windows, or travel, swapping less often matters more than the tag price.

- Safety windows are tight. Fewer interventions lowers exposure time. That’s risk you just removed.

If any two of those bullets ring true, UHMWPE’s lifecycle wins. The crying stops after the first PO.

Where HDPE Still Makes Solid Sense

HDPE is not a compromise; it’s a smart baseline when:

- Loads are modest, surfaces are smooth, and rubs are rare.

- Flat panels need to stay neat and dimensionally tidy.

- You want clean fabrications—welds, formed panels, covers—without fighting the machine all day.

- Replacements are easy and cheap to do (good access, quick turnaround, small crew).

In short: if your part isn’t a wear part (or it’s low duty), HDPE keeps the bill lean and the install simple.

Field Scenes You’ll Recognize

1) Aggregate chute liner—lots of fines, lots of friction.

HDPE worked… for a bit. But throughput dropped as fines stuck and hot spots built up. UHMWPE liner, same geometry, ran smoother, fewer jams. The crew said, “we stopped baby-sitting it.” Less babysitting = more tons thru. Sounds small, but it adds up.

2) Event flooring, light-to-moderate foot + cart traffic.

HDPE panels were fine because the traffic was spread, & swaps were easy. UHMWPE would’ve been overkill. Save your premium for the tough stuff.

3) Crane outrigger pads, point loads, repeat cycles.

UHMWPE took the cyclical pounding better, with cleaner surfaces after a season. That’s not magic—just toughness + low friction keeping gouges down.

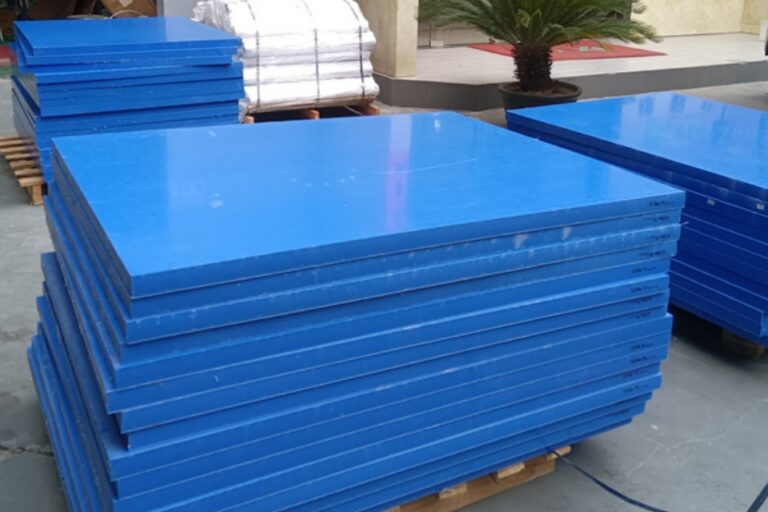

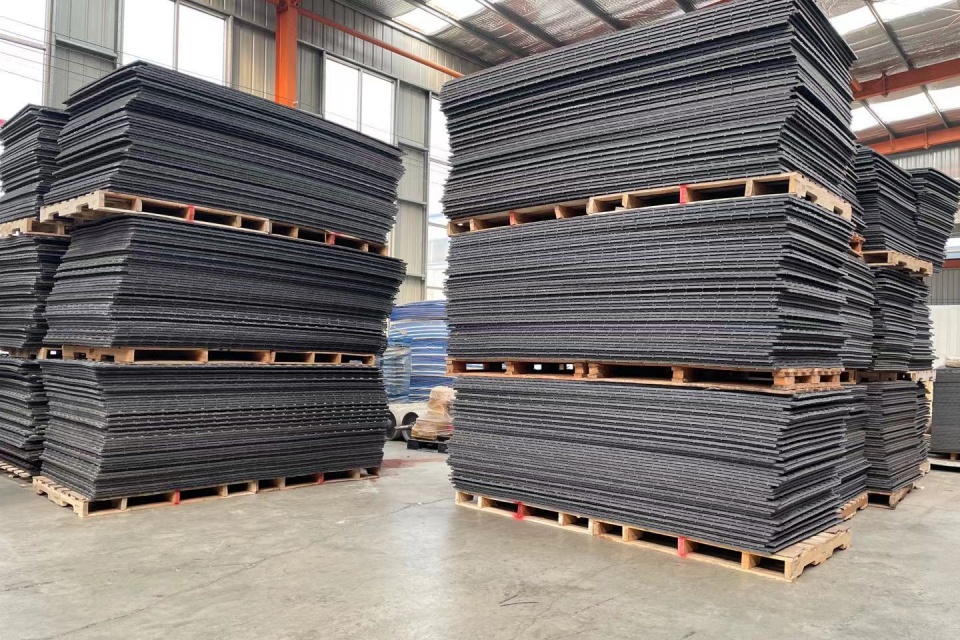

Base Mats & Ground Protection: Why UHMWPE Pulls Ahead

When we talk temporary roadways, crane pads, laydown yards, events, we care about four things:

- Load distribution over soft subgrade.

- Surface resilience under point loads and turning wheels.

- Fast handling (less stuck, less suction, less dragging).

- Repeat deployments without the edges chewing out.

UHMWPE checks those boxes reliably. The low friction helps mats release from muddy beds and each other. Impact toughness keeps corners alive thru forklift kisses and track turns. For heavy kit, that extra resilience turns into fewer broken panels and fewer emergency swaps. If you’re shopping this category, see our Base Mats for sizes, textures, and connection options—and our broader ground protection lineup for access roads and staging.

Quick Reality Check: Don’t Over-Spec (or Under-Spec)

- If your failure mode is wear → UHMWPE.

- If your failure mode is stiffness → HDPE sheet or plate.

- If your pain is downtime or access → UHMWPE saves headaches.

- If your pain is first-cost and swaps are trivial → HDPE keeps it tidy.

That’s it. Not fancy, just honest.

A Simple Selection Grid (thumb rule)

| Your Situation | Pick | Why |

|---|---|---|

| Sliding contact all day, grit everywhere | UHMWPE | Lower CoF and superior abrasion handle the grind. |

| Flat guard, low duty, easy access | HDPE | More rigid, easier to fabricate, budget-friendly. |

| Crane / outrigger / rub points | UHMWPE | Soaks impact, edges last longer. |

| Tank, cover, outdoor cabinetry | HDPE | Stable panels, clean welds, quick to make. |

| Base mats / ground roads with tracked gear | UHMWPE | Resists chipping, releases from mud, survives cycles. |

| Easy swaps, cheap labor, light traffic | HDPE | No reason to overspend here. |

TCO Mindset Without the Calculator

Even without numbers, you can feel it: if a part runs hot, drags, chips, or keeps you rolling trucks for service, the “cheap” option isn’t cheap. UHMWPE doesn’t just last longer; it stays friendlier under abuse. If a part mostly just sits there, HDPE is the right simplifier.

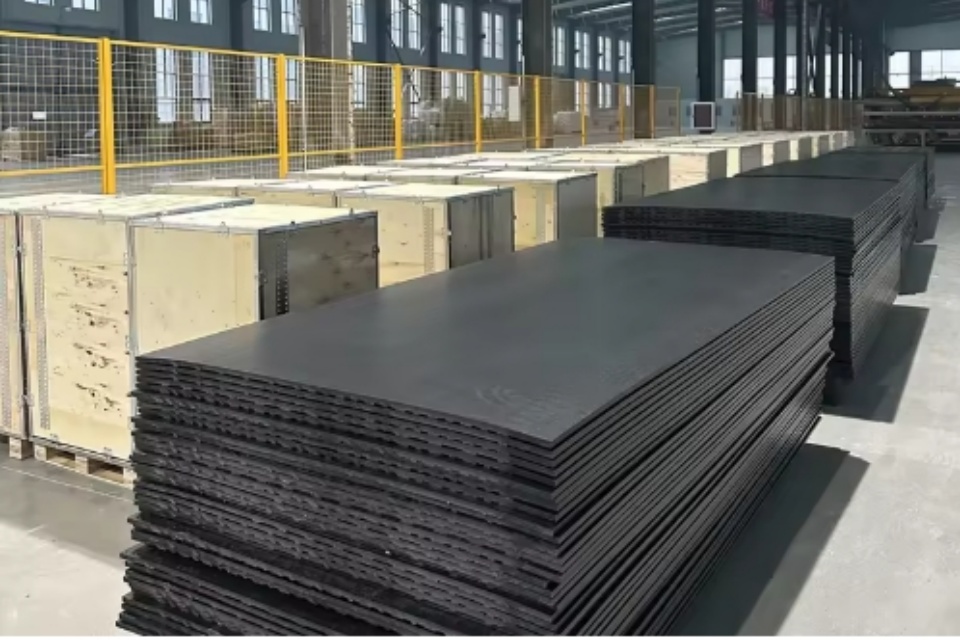

Fit for Your Operation: OEM/ODM and Batch Orders

We’re High-Performance Engineering Plastic Products Manufacturer focused on UHMWPE & HDPE: sheets, fender pads, outrigger pads, ground mats,and more. We handle customization, bulk wholesale, OEM/ODM for buyers who need repeatable spec and reliable lead times. Typical sample windows run 3–15 days, production 3–20, with 24-hour response from our team—so you dont wait ages for a straight answer.

If your job touches civil works, events, rental fleets, crane ops, ports, mining, or ag, we can tune resin grade, texture, connection hardware, and thickness for your scene. Start with base mats, then tell us the soil, loads, and handling gear—you’ll get a design that isn’t “pretty on paper,” it’s workable on Wednesday.

One More Industry Note: Dongxing Rubber

You’ll also hear the name Dongxing Rubber in ground protection and industrial pad conversations. In many supply chains, rubber and UHMWPE live side-by-side: rubber for grip and energy damping, UHMWPE for sliding and wear life. When projects blend both—say, rubber underlayment with UHMWPE base mats up top—you get a hybrid that rides softer yet still resists gouging. If your spec calls for mixed media, we speak that language too.

Final Take: When to “Buy Once, Cry Once”

- Yes: abrasive sliding, frequent impact, ugly access, or high safety sensitivity → UHMWPE.

- No: light duty, easy access, stiff panels, quick swaps → HDPE.

If you’re still 50/50, send a short brief: load, terrain, traffic type (tracks, tires), swap cost (crew/time), and your pain points. We’ll point you to the right sheet or the right base mats configuration—and keep your project moving, not stuck in the mud.