-

Tian Dong Industrial Park, Decheng District Economic and Technological Development Zone, Dezhou City

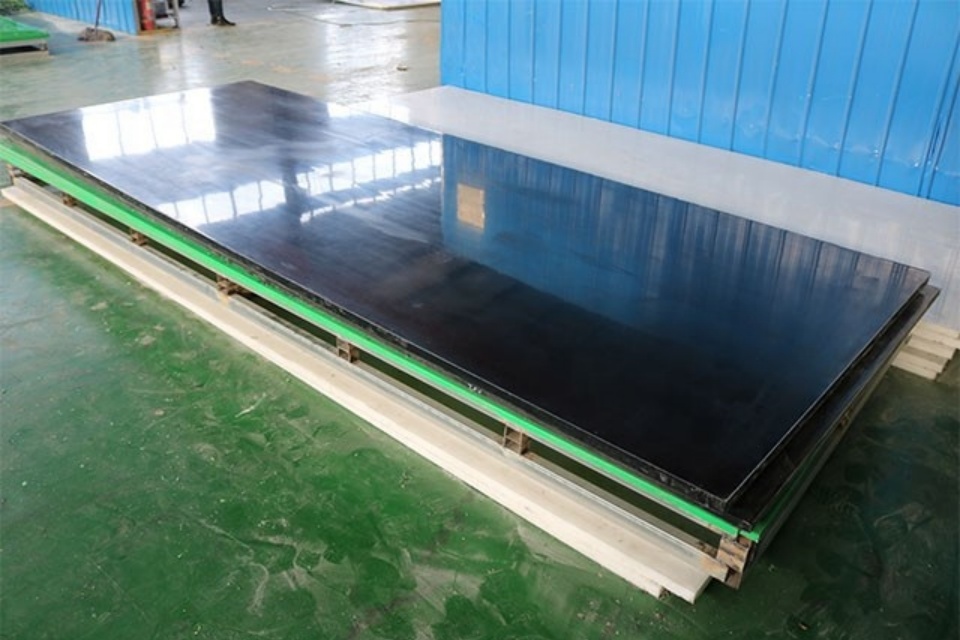

Tolerances & Flatness: What’s Realistic For Large PE Plates?

If you buy big PE plates and expect them to behave like ground steel, you’re going to be disappointed.

PE is not steel, and that’s actually fine — as long as you set the right tolerance and flatness targets from day one.

In this article, let’s talk in a very real way about what’s actually possible on large HDPE and UHMWPE plates, and how a supplier like Dongxing Rubber can help you hit the sweet spot between “good enough” and “over-spec”.

Table of Contents

Why Big PE Plates Can’t Be As Flat As Steel

PE (HDPE, UHMWPE) has a much higher thermal expansion and a much lower stiffness than steel. That means:

- Small temperature change → visible movement.

- Internal stress from extrusion / pressing → the plate wants to warp a bit.

- Machining on one side only → “banana board” effect.

So when someone says, “I want a 2 × 3 m PE plate dead flat like a granite table,” you already know the answer: not realistic.

Large UHMWPE HDPE sheets & plates will always move a few millimeters across the length when temperature, humidity, or clamping conditions change. The trick is not to fight physics, but to design tolerances around it.

Thickness Tolerances for HDPE and UHMWPE Plates

Let’s start with thickness. Customers often send drawings with “±0.1 mm on 30 mm plate” and wonder why every supplier says “no way”.

In normal industrial practice, typical ranges look more like this:

HDPE and UHMWPE Plate Thickness Tolerance Range

| Plate type | Typical thickness range (mm) | Supply status | Realistic thickness tolerance* |

|---|---|---|---|

| Extruded HDPE sheet (4×8 ft type, 3–12 mm) | 3–12 | Standard extruded, not milled | about ±0.2 to ±0.5 mm |

| UHMWPE sheets for liners / pads | 6–100+ | Pressed / extruded, rough cut | often +2 / −0 mm |

| Precision-milled UHMWPE plate (both sides skim) | 5–100 | Double-sided machined | about ±0.1 to ±0.2 mm |

| Economy UHMWPE plate (no milling, just sawn) | 10–100+ | Sawn, surface not very smooth | +2 / −0 mm or even looser |

You can see the pattern:

- Standard extruded HDPE: quite good on thin plate, but not metrology-grade.

- Big UHMWPE sheets: suppliers normally protect themselves with +2 / −0 mm.

- Milled plates: yes, you can get tighter numbers, but you pay with extra machining, more scrap, longer lead time.

If your project needs sliders, liners, or ground protection pads, you usually don’t need ultra-tight thickness. For those jobs, standard UHMWPE sheets or milled UHMWPE HDPE sheets & plates already work very well.

Flatness Over 2–3 m: What mm Per Meter Is Realistic

Thickness is one thing. Flatness on a 2–3 m plate is another story completely.

Most big PE plates are measured in mm per meter, not in microns. That’s a key mindset change for many buyers.

Typical Flatness Expectations for Large PE Plates

| Situation / plate type | Approx. flatness level | What that means in practice |

|---|---|---|

| Standard HDPE sheet (extruded) | ~2 mm per meter | 2 m span → about 4 mm bow, 3 m → about 6 mm bow |

| Thick UHMWPE liner plate | ~2–3 mm per meter | 2 m span → 4–6 mm, 3 m → 6–9 mm |

| Milled and stress-relieved PE plate | ~1–2 mm per meter | better, but still not “stone flat” across 2–3 m |

| Over-tight spec (“only 1 mm on 3 m”) | not stable | maybe OK at factory, warps again in your workshop |

Is 4–6 mm bow on a 2 × 3 m UHMWPE sheet really so terrible?

For most ground protection mats, ice rink dasher boards, or conveyor liners, absolutely not. The part is bolted down, clamped, or supported by structure. Once fixed, that small wave disappears for the user.

Plate Flatness vs Machined Part Tolerance

One big misunderstanding:

- Plate flatness = how the raw plate looks when it lies free on a table.

- Machined part tolerance = what we can hold on a local feature after clamping.

When Dongxing Rubber machines UHMWPE HDPE sheets & plates, we don’t just throw them on the CNC bed and hope. We:

- Use vacuum tables or strong mechanical clamps.

- Support the plate properly to avoid “drum skin” vibration.

- Rough-machine first, then finish in smaller passes.

On a big plate that is slightly bowed overall, we can still hit tight local tolerances on:

- Hole positions

- Slot width

- Counterbores

- Pocket depths

Is ±0.1 mm always possible? Not on a 3 m span, of course. But on a small feature area, with a good setup, ±0.1–0.2 mm is very realistic on HDPE or UHMWPE. The raw plate may look a bit potato, but the critical features still land in tolerance.

For you as a buyer, the key is:

Put tight tolerance only where it really matters (hole pattern, key slot, bearing seat), not on the whole 2 × 3 m outline and whole surface.

How Process Choices Improve PE Plate Flatness

If you really care about flatness and stability, process flow matters a lot. Here’s what we normally look at inside the factory.

Stress Relief and Annealing

PE plates store a lot of internal stress from extrusion or pressing. When you machine one side, that stress release makes the plate move.

Easier way to say it: you cut, it bends.

To reduce this, we can:

- Rough-machine both sides, leave some allowance.

- Do a heat treatment / stress relief step (controlled heating and slow cooling).

- Then come back for final machining.

This sequence doesn’t turn PE into steel, but it cuts down the “after-machining surprise” a lot.

Symmetric Machining

If you hollow out one side very deep and leave the other side intact, you almost invite a big warp.

So on many UHMWPE sheets for ice rink boards, fender pads, or sliding blocks, we:

- Try to remove material more symmetrically.

- Add back-side pockets or relief cuts to balance the stress.

- Keep wall thickness more uniform instead of super thick here and super thin there.

This sounds like small details, but shop guys know: this is the difference between a plate that lies nice on the frame and a plate that your team needs to “fight” during assembly.

Setting Realistic Tolerances With Dongxing Rubber

When you work with Dongxing Rubber, we normally break the discussion into three blocks:

1. Plate Supply Level

- Do you need standard UHMWPE sheets for your own machining?

- Or do you need milled UHMWPE HDPE sheets & plates with tighter thickness and better surface?

For many Ground Protection & Road Mats or PP/PE Products, standard plate with normal flatness is enough. For precision guides or wear strips, milled plate makes more sense.

2. Functional Areas vs Non-critical Areas

On your drawing, we like to see:

- Tight tolerances only on holes, slots, datum faces.

- Reasonable numbers on plate outline and overall flatness.

- Notes like “flatness 2 mm per meter is acceptable” instead of “perfectly flat”.

This helps keep cost under control (no need to quote crazy operations) and makes delivery more stable.

3. Scene and Usage, Not Just Numbers

We’ll always ask you boring questions like:

- Is this for ground mats, ice rink products, crane outrigger pads, or general MG engineering plastic parts?

- Is the plate fully clamped, just supported, or free-standing?

- Is it outdoor, with big temperature swings, or inside a cool warehouse?

Sometimes the drawing looks strict, but the real working condition is very forgiving. In that case, relaxing flatness from “too perfect” to “industry normal” makes everyone happy. You still get a clean running system, but with a more friendly lead time and price level

Final Thoughts

Large PE plates will move. They will bow a bit. They will react to temperature. This is not a defect, it’s just how HDPE and UHMWPE live.

If you:

- Use thickness tolerances that match reality,

- Think in mm per meter for flatness,

- Separate plate flatness from machined feature tolerance,

- And choose the right process flow,

then PE becomes a very reliable, cost-efficient workhorse for Ground Protection & Road Mats, Ice Rink Products, Nylon Sheets, PP/PE Products, and other MG Engineering Plastic Sheets scenes.

If you’re not sure how far you can push the tolerance on your next big PE plate project, send the drawing and usage info to Dongxing Rubber. We can walk through the spec with you, in real shop language, not just nice theory words, and find a level that works on the machine and in your market.