-

Tian Dong Industrial Park, Decheng District Economic and Technological Development Zone, Dezhou City

Salt, Sun, And Surge: Marine Weathering Of UHMWPE

If you work near the ocean, you already know the vibe. Metal rusts fast. Paint chalks. Rubber swells. And plastic? People often assume it “just lasts.”

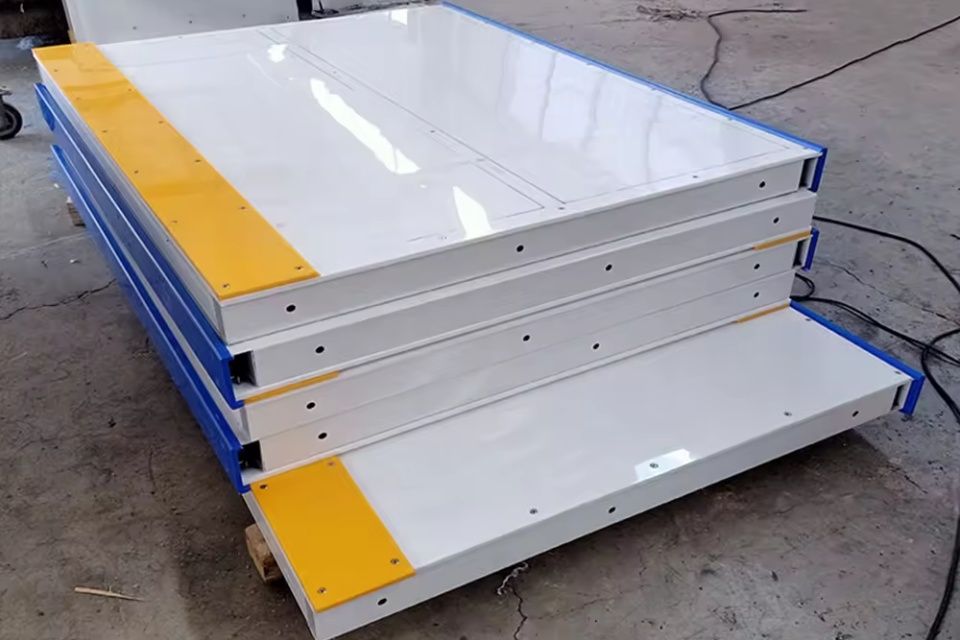

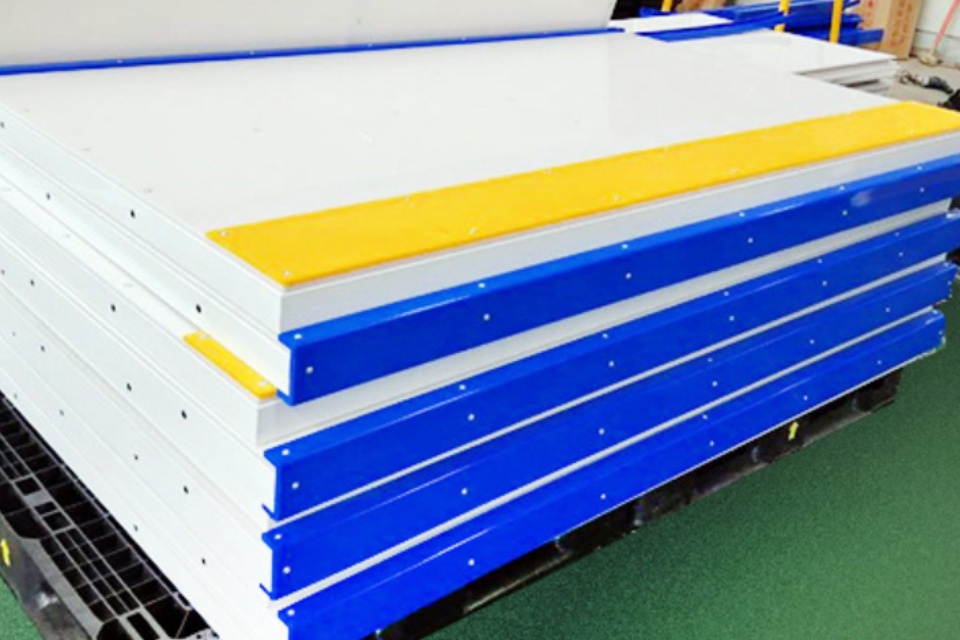

UHMWPE does last. It’s tough. It slides well. It takes hits. That’s why you see it in marine fender pads, liners, and also sports barriers like dasher boards. But coast-side use still brings real wear. Not dramatic at first. More like a slow drip.

This article argues one simple idea: salt, sun, and surge don’t attack UHMWPE the same way. Salt plays support. Sun starts the trouble. Surge (impact + abrasion) finishes the job.

If you’re planning custom OEM/ODM parts for coastal arenas, ports, or outdoor sport courts, you’ll want to design for all three. And yes, even for Floor Ball Dasher Boards.

Table of Contents

Salt Spray and Chloride Ions

Salt spray looks harmless. It’s not acid. It doesn’t “corrode” UHMWPE like it does steel. But salt still matters, because it pushes other damage forward.

What Salt Really Does to UHMWPE

Salt doesn’t usually break UHMWPE chains by itself. Instead, it:

- stays on the surface as a crust,

- holds moisture longer, and

- gets into tiny scratches and keeps them wet.

That last point matters a lot. UHMWPE often starts failing from the surface. Once you get micro-cracks, moisture and salts can sit there. Then the next impact or scrape opens them wider. It’s like sand in a zipper. Not deadly alone, but it makes every move rougher.

Salt Fog Testing and “Fake Sea Water” Practice

Use known methods:

- ASTM D1141 (standard practice for preparing substitute ocean water)

- Salt fog / salt spray exposure (often used in industry for corrosion and general durability screening)

Even if UHMWPE won’t rust, these tests still help you compare:

- different resin grades,

- different UV packages,

- different surface textures, and

- different fastening designs.

And real talk: salt spray are messy. If your board design traps brine in seams, you’ll see grime lines and creep marks faster.

UV Radiation and Photo-Oxidation

UV is usually the main driver for outdoor plastic aging. Ocean locations make it worse because sunlight hits hard, and reflections off water increase exposure.

Chain Scission and Surface Embrittlement

UV can start photo-oxidation. That’s a fancy way to say: sunlight helps oxygen react with the polymer surface. Over time, the surface can:

- lose ductility,

- get brittle,

- form micro-cracks,

- show “chalking” or a dull look.

Here’s the tricky part. The board can still feel “strong” when you push it. But the skin can weaken. Then a sharp hit creates a white stress mark. Next, you see tiny splits near corners or fasteners.

UV Stabilizers and Color Choices

If you’ve been in plastics long enough, you’ve heard the shop talk:

- “Black lasts.”

- “Clear dies fast.”

There’s truth there. Many outdoor UHMWPE parts use carbon black or other UV stabilizers to slow aging. That doesn’t mean every project must be black. But it does mean you should plan your color like you plan your thickness.

If you need bright colors for floorball branding, you can still build in protection with:

- UV-stabilized compounds,

- thicker “sacrificial” wear layers,

- replaceable strips where the sun hits hardest.

Wave Impact, Abrasion, and “Surge Loading”

“Surge” isn’t only waves. It’s any repeated hit, shove, vibration, or scrape that happens in a wet, gritty place.

For marine facilities, surge can mean:

- floating docks rubbing against panels,

- ropes and hooks dragging,

- sand grinding in contact zones,

- forklift bumps in salty air.

For sport barriers near the coast, surge can look like:

- players hitting boards at speed,

- equipment carts slamming corners,

- constant cleaning + squeegee scraping,

- parts shifting during shipping and install.

Stress Concentration at Fasteners and Joints

This is where many UHMWPE parts lose the fight.

A sharp corner, tight bolt pattern, or thin edge can turn normal loads into local stress spikes. Add UV-aged surface skin, add salt-held moisture, then add repeated impacts… and you get:

- hole ovalization,

- edge cracking,

- loosened hardware,

- squeaks and rattles (operators hate that).

If you design Floor Ball Dasher Boards, you want quiet boards. You want stable panels. Nobody wants that “clack-clack” line every time a player leans in.

Marine Cleaning Chemicals and “Rink Reality”

In real venues, crews clean fast. They don’t baby surfaces. They may use:

- alkaline cleaners,

- disinfectants,

- hot water,

- stiff brushes.

UHMWPE handles many chemicals well, but cleaning still adds abrasion. And scratches act like UV collectors. That’s not official science talk, but in the field it’s true: rough surfaces age faster, and they look old sooner.

A Simple Evidence Table

| Exposure factor | What you’ll see first | What it can turn into | Quick test / check | Design moves that help |

|---|---|---|---|---|

| Salt spray (chlorides) | grime lines, wet seams, surface staining | more scratch growth, fastener zone creep | salt fog screening, seam inspection after soak | seal/cover seams, avoid brine traps, add drain paths |

| UV radiation | dull surface, color fade, white stress marks | brittle skin, micro-cracking | UV lamp or xenon exposure cycles, bend checks | UV-stabilized compound, darker pigments, thicker wear layer |

| Surge impact (hits) | denting, edge scuffs, rattling | cracks at corners/holes | repeated impact test, corner drop checks | radiused corners, backing plates, better support spacing |

| Abrasion (sand/brush) | scratch haze, rough feel | faster UV aging look, wear-through | abrasion screening, surface roughness checks | smoother contact strips, replaceable wear bars, thicker face |

| Combined salt + sun + surge | “fine” at first, then sudden ugly spots | crack network around holes | combo exposure plan | treat it as a system, not one test |

What This Means for Floor Ball Dasher Boards

You might think, “Dasher boards aren’t marine parts.” Sure. Most are indoors.

But these coastal scenarios happen all the time:

- An arena sits near the sea. Doors open. Salt air gets inside.

- Boards ship through a port and sit outside for weeks.

- An outdoor floorball court uses boards year-round.

- A venue stores boards in a humid loading bay.

In those cases, the same trio shows up: salt, sun, surge.

If you’re building boards for these places, you want:

- stable panels that don’t warp easily,

- tough surfaces that stay smooth,

- joint designs that don’t trap wet grit,

- hardware zones that don’t crack early.

At High-Performance Engineering Plastic Products Manufacturer, we focus on custom OEM/ODM, bulk supply, and wholesale needs. We can tailor thickness, color, surface finish, and mounting style for your exact install. We also understand mixed-material setups.

The Takeaway

Salt rarely kills UHMWPE alone. Sun usually starts the aging. Surge and abrasion make the weak spots show up fast.

So don’t pick material like it’s a checkbox. Pick it like you’re planning a season of use. Think about where water sits. Where sunlight hits. Where carts slam. Where people lean. Then design the board so those spots don’t become the first failure.

If you do that, UHMWPE stays what you bought it for: a hard-wearing, low-friction panel that keeps working even when the environment don’t play nice.