-

Tian Dong Industrial Park, Decheng District Economic and Technological Development Zone, Dezhou City

Recycling Uhmwpe/Hdpe Offcuts: Options And Traceability

If you run CNC cutting, router lines, or sheet fabrication, you know this pain very well:

the ground protection mats and Amphi Mats go out, but the UHMWPE/HDPE offcuts stay.

They sit in big bags, eat warehouse space, and nobody has time to deal with them.

Some factories just send them to landfill and call it a day.

But honestly, those offcuts are not trash.

They’re clean, single-material engineering plastic.

If you treat them right, they can become a stable recycled material stream and even help you win bigger projects.

In this article we talk about:

- realistic recycling options for UHMWPE/HDPE offcuts

- what you can actually do with the recycled material

- how to build traceability that buyers trust

- where a supplier like Dongxing Rubber fits into this picture

Table of Contents

Why UHMWPE/HDPE Offcuts Are Premium Recycling Material

When people hear “plastic waste”, they often think of dirty household trash.

Your reality is different.

In a typical sheet shop or mat factory:

- you start from known UHMWPE or HDPE grades

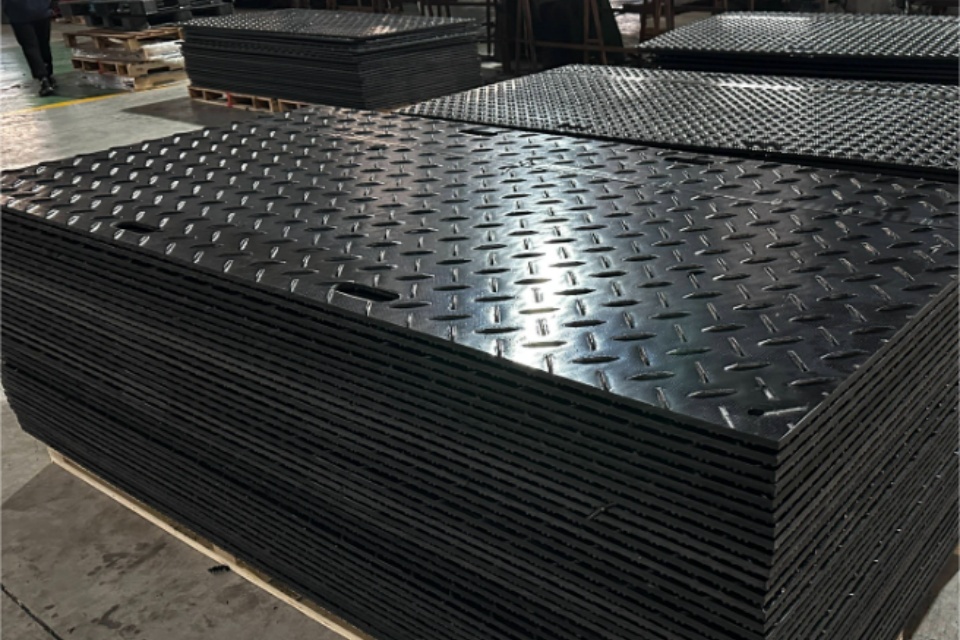

- you cut standard sizes for ground protection & road mats or Amphi Mats

- offcuts fall from a controlled process, not from the street

That means your offcuts usually are:

- clean (little oil, no food, no sand if you keep good housekeeping)

- single polymer (UHMWPE or HDPE, not random mixed plastics)

- from known batches (you know which lot number, which supplier)

For recyclers and for your own closed loop, this is gold.

Compared with mixed consumer waste, offcuts are much easier to sort, re-melt, and re-use.

So the first mindset change is simple:

Offcuts from your UHMWPE/HDPE mats are not just “waste”.

They’re high-grade feedstock if you handle them correctly.

Mechanical Recycling Options For UHMWPE/HDPE Offcuts

The most realistic road for most factories is still mechanical recycling:

you keep the polymer in solid form and just reprocess it.

Mechanical Recycling Of UHMWPE Offcuts

UHMWPE is trickier than “normal” HDPE.

The melt flow is low, it doesn’t like to move, and processing window is narrow.

Still, you can do this:

- Segregate scrap streams

- Separate UHMWPE offcuts from HDPE

- Keep colors separated if possible (white / black / mixed)

- Shred or granulate the offcuts

- Use heavy-duty shredder

- Avoid metal chips and dirt from the workshop floor

- Re-extrude or press

- Make reprocessed UHMWPE sheets

- Use them in non-critical positions: back layers of mats, wear pads, liner plates, etc.

You don’t aim for the same cosmetic level as high-gloss new sheet.

You aim for good mechanical properties at lower material cost.

Mechanical Recycling Of HDPE Offcuts

HDPE offcuts are more easy to reprocess.

You can:

- shred → wash (if needed) → extrude → make pellets

- or directly press into recycled HDPE boards

- use them in ground protection & road mats where surface finish is not key

For example, Dongxing Rubber can design a two-layer road mat:

- top layer: virgin or high-grade PE for impact and UV stability

- core or bottom layer: recycled HDPE/UHMWPE blend from your own offcuts

You use your scrap as a core material, but the customer still sees a nice, clean surface.

Table 1 – UHMWPE/HDPE Offcut Recycling Options

| Recycling option | Typical process | Main products | Pros | Limits | Typical uses |

|---|---|---|---|---|---|

| Mechanical recycling – UHMWPE | Segregate → shred → press/extrude | Reprocessed UHMWPE sheets, liners | Keeps material in loop, good wear resistance | Processing window narrow, need strong machines | Chute liners, backing plates, non-visible parts |

| Mechanical recycling – HDPE | Segregate → shred → wash → pelletize/press | Recycled HDPE boards, panels | Easier flow, common equipment | Some drop in mechanical properties | Ground mats, trench covers, walkways |

| Hybrid UHMWPE/HDPE blends | Controlled mixing of UHMWPE & HDPE granules | Structural cores, heavy blocks | Use both types of offcuts, better toughness than pure HDPE | Need testing to avoid warpage and inconsistent shrinkage | Core of road mats, Amphi Mats support zones |

| External recycler route | Ship offcuts to specialized recycler | Pellets or boards, maybe back to you | Lower internal workload | Less control on traceability and quality | Low-risk start if you don’t want to buy machines now |

Real Project Scenarios For Recycled UHMWPE/HDPE

Let’s get away from theory and talk real floors, real mud, real trucks.

Scenario 1 – Recycled Core In Ground Protection & Road Mats

You sell heavy duty ground mats into:

- construction access roads

- wind farm sites

- pipeline job sites

Most clients care about:

- load capacity

- anti-slip pattern

- connector system

They usually don’t care if the inside core is virgin or recycled, as long as:

- the mat doesn’t crack

- the surface stays safe

- documentation for recycled content and traceability is clear

Here Dongxing Rubber can help design:

- sandwich structures (virgin skin + recycled core)

- clear data sheets that show recycled content range

- stable production so mat weight and flex is consistent from batch to batch

Scenario 2 – Wear Parts And Liner Plates From Reprocessed Sheets

Your offcuts from big sheets can turn into:

- small UHMWPE wear strips

- chain guides

- liner panels for bins, hoppers, truck beds

Customer pain points here:

- steel wears fast and noisy

- they don’t want high cost for every liner change

- they’re under pressure to show “green” purchasing

Reprocessed UHMWPE sheet is perfect for this.

It slide well, it resist impact, and it uses your waste as raw material.

You can tell your customer in a simple way:

“This liner uses recycled UHMWPE from our own offcuts,

it reduce landfill and still run smooth for your bulk material.”

Traceability Requirements For Recycled PE In B2B Projects

Now the harder part: traceability.

Buyers don’t just ask “is it recycled”.

They ask:

- “from where?”

- “how much?”

- “is it safe?”

If you want to sell to serious industrial clients, EPCs, or global rental fleets, you need a traceable system, not only a story.

Basic Traceability For Industrial Customers

At minimum, your system should track:

- which line the offcuts came from

- which polymer grade and color

- when they were shredded and pressed

- which finished mats they go into

In industry language, you will hear words like:

- lot tracking

- scrap stream ID

- MTR (material traceability report)

Dongxing Rubber can issue simple reports like:

- “Batch DX-RM-2403 contains 45–55% recycled HDPE offcuts from ground mat line A.”

This already helps a lot when customers do ESG audits or supplier checks.

Higher Traceability For ESG-Sensitive Or Regulated Projects

Some buyers want more:

- large contractors with strong ESG targets

- brands who publish sustainability reports

- sometimes projects close to food, water, or public space

For them, you may need:

- documented scrap segregation rules (photos, SOP)

- test reports for heavy metals, VOC, contamination on recycled boards

- clear recycled content range on the data sheet

- signed statement that no unknown post-consumer waste is mixed in

This sounds heavy, and honestly sometimes it is.

But if you do it step by step with your supplier, it’s manageable.

Table 2 – Key Traceability Elements For Recycled UHMWPE/HDPE

| Traceability element | What you track | Customer benefit | Comment |

|---|---|---|---|

| Scrap source ID | Which machine/line created the offcuts | Buyer knows material origin is controlled | Avoid mixing random external waste with your clean scrap |

| Polymer type & grade | UHMWPE/HDPE, density, color | Confidence in mechanical properties | Important for mats that carry heavy trucks |

| Process records | Shredding, washing (if any), pressing dates and parameters | Helps QA if field issue appear | Many QC teams now expect at least basic process logs |

| Recycled content range | % range for each product type | Buyers can show ESG benefit without guessing | Not need exact %, but range must be honest and stable |

| Lot traceability for finished mats | Link each mat order to a recycled batch | Faster root-cause analysis and claim handling | Makes your project manager and QC life less painful |

How Dongxing Rubber Can Support Your Recycling Strategy

If you already buy Ground Protection & Road Mats or Amphi Mats from Dongxing Rubber, or plan to start, you don’t need to build everything alone.

A supplier with engineering plastics experience can help you:

- design mat structures that accept recycled cores

- decide which positions must stay 100% virgin (top skin, connection points, lifting eyes)

- test blends of UHMWPE and HDPE from your offcuts

- issue basic traceability paperwork for your key accounts

Because Dongxing Rubber already works with OEM/ODM projects and bulk orders, it’s normal work for them to:

- tune material recipe for your region and usage scene

- run trial lots with different recycled content

- keep cost and performance in a reasonable balance (not perfect, but good enough for field)

You don’t have to become a recycling expert.

You just need to:

- separate your offcuts

- keep them clean

- talk openly about your targets (cost saving, ESG, marketing story)

Then use Dongxing Rubber as your engineering partner to turn that pile of scrap behind the workshop into a repeatable product feature.

Conclusion: From Scrap Pile To Selling Point

Recycling UHMWPE/HDPE offcuts is not magic, and yes, it can be messy at first.

But the logic is simple:

- your offcuts are clean, high-grade material

- mechanical recycling gives you realistic, shop-floor-friendly options

- smart design lets recycled cores work inside ground mats and Amphi Mats

- basic traceability turns “we recycle something” into a story buyers actually trust

If you start small, keep your scrap streams tidy, and work with a manufacturer like Dongxing Rubber who understands both engineering plastics and OEM/ODM批量业务, that big bag of offcuts stop being only a headache.

It becomes one more reason why customers choose your mats instead of somebody else’s.