-

Tian Dong Industrial Park, Decheng District Economic and Technological Development Zone, Dezhou City

Mud, Sand, Or Turf: Picking The Right Mat Layout Patterns

You can buy the toughest mat on the planet, drop it on bad ground, and still watch it fail. I’ve seen it. The mat didn’t “break.” The layout broke.

So let’s talk like people on site talk. Your mat job usually dies in one of three ways:

- It sinks (rutting, pumping, bogging).

- It walks (joint spread, plate drift, edge lift).

- It tears stuff up (turf shear, scuffing, trip edges).

If you pick your pattern based on those failure modes, you stop guessing. You start building a route that rigs can actually use.

If you need product options while you plan, start here: Ground Protection & Road Mats and Base Mats.

- https://uhmwpe-manufacturer.com/ground-protection-road-mats/

- https://uhmwpe-manufacturer.com/base-mats/

Table of Contents

Ground Protection Mat Layout Patterns: Start With Failure Modes

Before you sketch a single line, ask one boring question:

“What’s the ground trying to do to me today?”

Rutting and mud pumping

Mud doesn’t just “look wet.” It acts like a soft sponge. Wheels push water and fines around. You get ruts, then pumping, then the mat starts rocking.

Joint spread and plate drift

If your connectors don’t hold, or your joints sit right under tires all day, the road slowly “unzips.” Crews call it mat walk. It’s annoying, then it’s unsafe.

Turf shear and surface scuffing

Turf fails in turns. Straight lines often survive. Corners don’t. A skid steer that pivots can peel grass like you’re opening a tin can.

Mud Ground Protection Mats: Overlap Direction and Drainage

Mud jobs punish lazy layouts. If you only do one thing right, do this:

Overlap like roof tiles

When mats overlap or link, point the overlap so traffic and water flow don’t drive mud into the seam. Think “roof tiles.” Water should shed, not dive under your mat.

For temporary roads and work pads, Base Mats with tread and locked connections help keep the surface stable while you move forklifts, trucks, or cranes.

Build a “bog pad” zone

If your access road hits a soft patch, don’t keep the same width and hope. That’s how you end up winching. Widen the road into a small pad, then transition back to the lane.

Practical site move:

- Widen at gates, turns, and low spots

- Run a staggered joint pattern through the soft section (more on that below)

- Keep edges tight so you don’t get a rolling lip

Sand Access Roads: Shear, Spin-Out, and Abrasion

Sand looks friendly until a loaded truck spins and polishes your tread. Then the lane turns into a beach wrestling match.

Widen the track where you turn

Sand failures happen at turns, braking zones, and start/stop points. That’s your hot zone. Make those zones wider, and keep joints out of that wheel path.

Keep joints out of the wheel path

If tires ride the same joint all day, sand works under it. The seam opens. The mat starts to chatter. Crews complain about “bouncing plates.”

A linkable, reversible mat style can help you reconfigure fast when the route shifts (and routes always shift). Quick Mat pages describe mats that are non-slip, reversible, linkable, and designed to build access roads and pads quickly.

Turf Protection Mats: Traffic Flow and Turns

On turf, the goal isn’t only “don’t sink.” It’s also “don’t wreck the lawn.”

Reduce turf damage at corners

Don’t make a sharp corner if you can avoid it. Build a gentle curve, or create a wider corner pad so machines can turn without pivoting on one spot.

Crew slang rule:

- No “spin turns” on grass.

- If the operator must pivot, give them extra mat width so they pivot on mat, not turf.

Pedestrian safety at edges

Events and walkways bring another problem: tripping. Keep edges aligned. Avoid random half-mat offsets where people step on an edge and roll an ankle.

Quick Mats are described as protecting turf while spreading load, which is exactly what you want when foot traffic meets equipment lanes.

Staggered and Brick-Bond Patterns: Joint Control for Real Sites

Straight runs look neat. Straight runs also fail first when traffic repeats.

Staggered joints for repeated traffic

If you expect the same wheel path all day (dumpers, telehandlers, MEWPs), stagger your joints so the tire doesn’t hammer one seam again and again. You’re basically moving the weak point away from the beatdown lane.

Brick-bond pattern for staging pads

For big work pads (crane setup area, laydown yard, pump station), use a brick-bond style. It spreads movement, reduces long “zipper seams,” and keeps the pad from creeping.

Base Mats and Ground Protection & Road Mats: Match the Product to the Pattern

Patterns solve half the job. The mat design solves the other half.

When to use Base Mats as a “foundation”

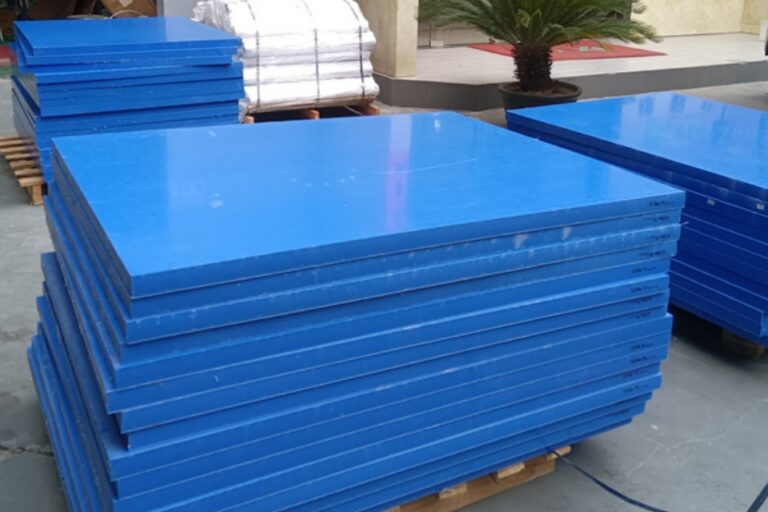

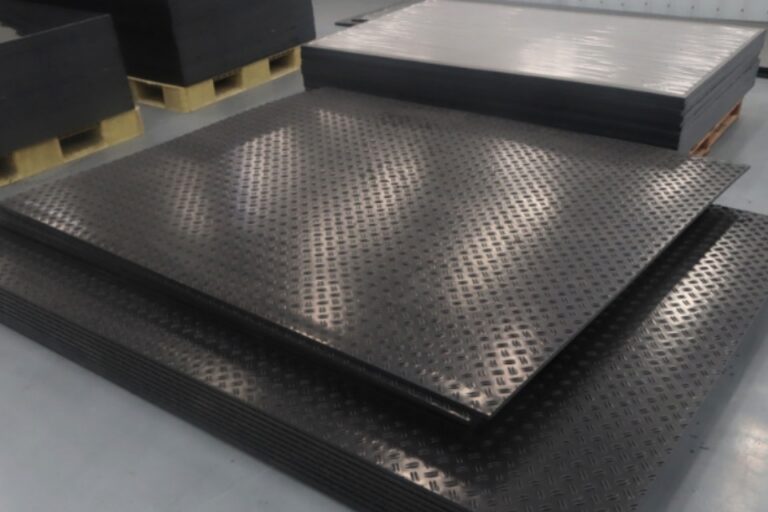

Use Base Mats when you need a stable platform more than you need speed. The Base Mat product page calls out diamond tread and steel connectors that lock panels, plus non-slip and reusable handling.

That’s helpful when:

- You’re carrying forklifts or truck traffic across mixed ground (grass/sand/concrete)

- You can’t accept drift at joints

- You need a pad that stays square, even when operators drive a little sloppy

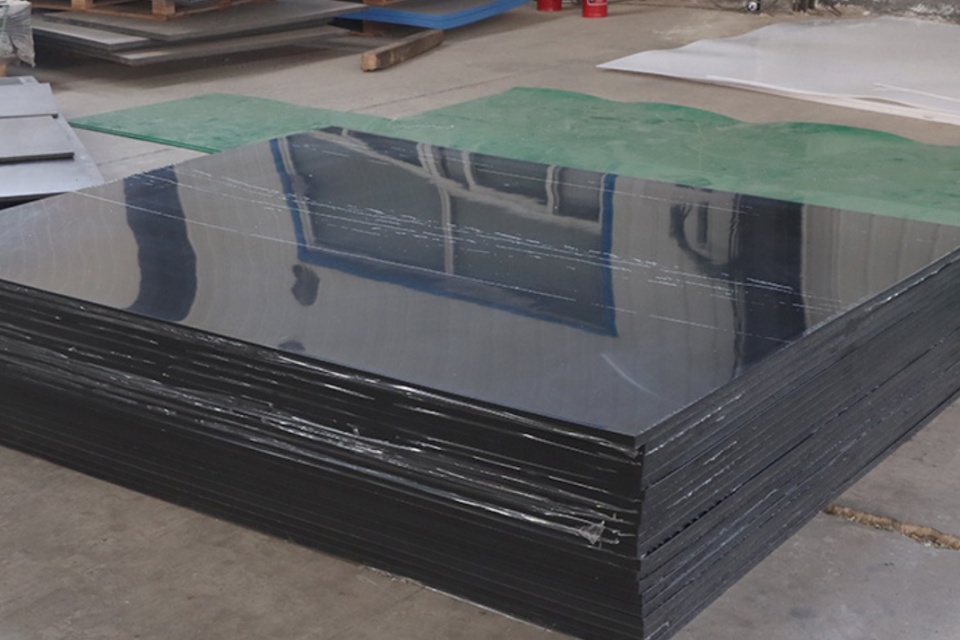

When to use Ground Protection & Road Mats for long routes

If you’re building longer access lanes, look at the broader Ground Protection & Road Mats range and pick by scene: fast deploy, heavy duty, or mixed surfaces. The category page also frames this as B2B supply with custom support.

Layout Decision Table: Mud vs Sand vs Turf

| Ground | What usually goes wrong | Best layout pattern | Extra field move (no fancy tools) |

|---|---|---|---|

| Mud | rutting, pumping, joint washout | overlap direction + staggered joints | widen low spots into a small pad |

| Sand | shear, spin-out, seam chatter | keep joints out of wheel path + wider turns | add corner pads at braking/turning zones |

| Turf | scuffing, turf tear, trip edges | planned curves + brick-bond pads | ban pivot turns, keep edges flush |

Pattern Cheat Sheet: What to build, fast

| Pattern keyword | What it looks like | Best for | Watch-out |

|---|---|---|---|

| Straight run | single lane, joints in lines | quick access lanes | joints get hammered by repeated traffic |

| Double width lane | two mats wide | heavy traffic lanes | needs edge control so it doesn’t flare |

| Staggered joints | “brick” offset in a lane | stop seam failure in wheel path | mark alignment or crews drift off line |

| Brick-bond pad | offset grid | crane pads, laydown areas | don’t leave random gaps at edges |

| Corner pad | widened area at turns | turf + sand turns | make it wide enough for real turning radius |

Work With a Manufacturer That Deals With Site Reality

Here’s the part buyers care about: you don’t just want mats. You want a supplier who won’t disappear when the ground turns ugly.

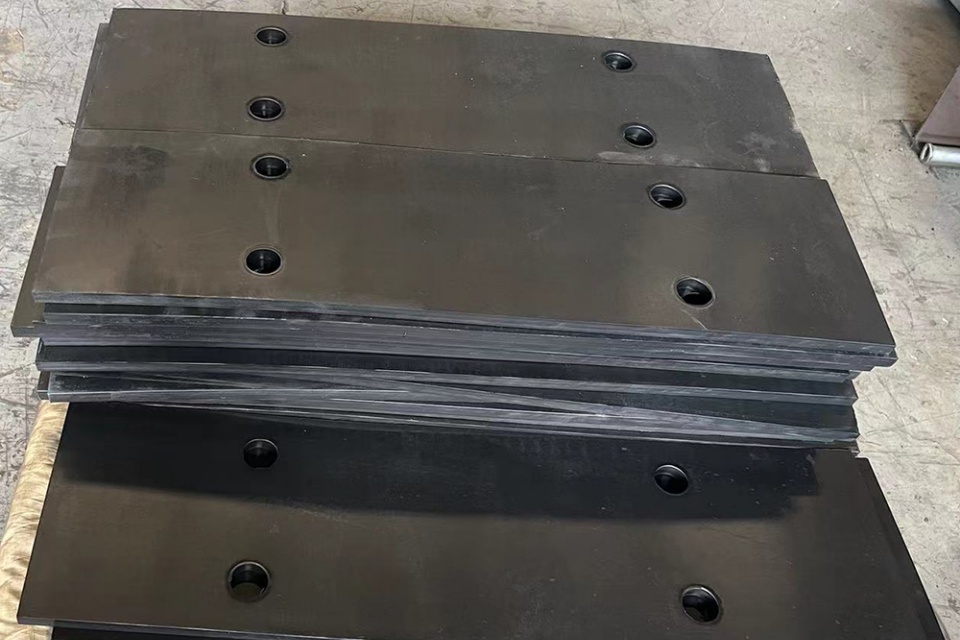

Dongxing Rubber & Plastic positions itself as a high-performance engineering plastic products manufacturer, with custom support, fast sampling, and fast response.

They also describe OEM/ODM and bulk wholesale work for repeat spec buyers, plus sample and production timelines (so you’re not waiting forever for “maybe next week”).

And yes, you’ll hear the name Dongxing Rubber in ground protection conversations. Rubber and UHMWPE/HDPE often show up in the same job stack. When your site needs both, it helps when one team speaks both “materials languages.”

If you want a clean recommendation, send three things:

- your ground (mud/sand/turf),

- your traffic (tires/tracks/foot),

- your pain point (sinking, drift, turf damage).

We’ll help you pick a mat and a layout that won’t go sideways on day two. And yeah, sometimes your site still gets messy—thats normal. The goal is to keep rigs moving, not arguing in the mud.