-

Tian Dong Industrial Park, Decheng District Economic and Technological Development Zone, Dezhou City

Mat Surface Textures: Grip For Tires Vs Tracks Vs Pedestrians

You’ve seen it on a jobsite. One crew rolls in with trucks. Another shows up with a tracked skid steer. Then people start walking across the same mats with wet boots and coffee in hand. Everyone wants “more grip.” But here’s the problem: tires, tracks, and pedestrians don’t “grab” the same way. If you pick one texture for all three, somebody will complain. Sometimes they’ll slip. Sometimes the machine will spin. Sometimes the mat just becomes a mud-slick pancake.

My take is simple: the best mat texture is the one that matches your traffic type and your mess (water, mud, grit, oil). Not the one that looks aggressive in a photo.

Table of Contents

Microtexture vs Macrotexture

Texture isn’t one thing. It’s more like two layers working together:

- Microtexture = tiny roughness that creates basic friction.

- Macrotexture = bigger grooves/peaks that move water, bite into dirt, and break surface films.

Here’s a quick way to picture it: microtexture is “sandpaper feel.” Macrotexture is “tread pattern.”

| Texture scale | Typical wavelength range | What it helps most | Real-world mat meaning |

|---|---|---|---|

| Microtexture | 1 μm to 0.5 mm | Base friction (dry + low speed) | Helps tires and shoes “start” without sliding |

| Macrotexture | 0.5 to 50 mm | Wet traction + drainage | Gives water/mud a place to go, reduces skating |

| Megatexture | 50 to 500 mm | Ride/comfort/noise (more than grip) | Big bumps can feel sketchy underfoot |

If your mat face has only “pretty” small bumps, it may feel okay when dry. The moment rain hits, it don’t drain well.

Tires: Wet Grip, Drain Paths, and Hydroplaning

Tires love consistent contact. They also hate trapped water. When water sits between rubber and mat, you lose friction fast. That’s when you get that annoying “spin-out” moment while you’re trying to climb a ramp or turn a loaded trailer.

Macrotexture for drainage grooves

For tires, you usually want a surface that:

- Pushes water out sideways, not just “looks rough”

- Keeps the contact patch stable when turning

- Doesn’t create so much vibration that operators slow down (or curse you)

In practical terms, tire-friendly mat faces often use:

- Shallow channels (so water can escape)

- Repeating lugs (so the tread always finds a “next bite”)

- A direction (some patterns work better if you lay mats the right way)

Jobsite example:

A concrete pump truck creeps across mats after a rain. If the mat has no drainage routes, the front tires can “float” for a second and slide sideways. That’s when you see ruts, edge lift, and drivers getting nervous.

Tracks: Shear, Cleats, and Mud Packing

Tracked machines don’t behave like tires. Tracks create traction by shearing the ground surface. They want “bite.” They also love to turn in place, which means they can shred a weak surface.

So for tracks, you’re balancing two things:

- Enough height/edge to resist sliding

- Enough spacing so mud doesn’t pack into the pattern and turn it smooth

Cleat-style texture and “bite”

Tracked equipment tends to perform better on mat faces that have:

- More pronounced cleats/lugs

- Wider gaps between features (for self-cleaning)

- High resistance to squirm (if the mat flexes too much, traction feels mushy)

Field scene:

A mini-excavator climbs out of a muddy trench. If the mat texture is too fine, the tracks polish it with mud in about ten seconds. Then the machine “walks” sideways. People call that “track slip,” and it’s bad news near slopes or open edges.

One more thing: tracks can also create edge curl and connector stress. If your pattern is super tall but your mat system can’t handle twisting forces, you’ll see broken links and ugly seams.

Pedestrians: DCOF, Contaminants, and Trip Hazards

Now the human part. A walking surface needs grip, yes. But it also needs:

- Predictable footing

- Low trip risk

- Easy cleanup (because somebody will spill something)

DCOF (Dynamic Coefficient of Friction) as a reference point

Many flooring specs use wet DCOF testing as a benchmark. A number you’ll see a lot is 0.42 for interior wet walking conditions. It’s not a magic shield, but it’s a useful anchor when you talk to safety teams.

Still, don’t fall into the trap of “higher number = always safer.” In real life, slip risk changes with:

- Shoe outsole material

- Mud, sand, oil, algae, ice melt

- Walking speed and slope

- Maintenance (how often you clean)

And here’s the kicker: a surface with big 3D bumps can feel “grippy,” yet it may also cause trips. You don’t want a pedestrain surface that acts like a mini obstacle course.

Example you’ll recognize:

Event crews carry cases, walk fast, and don’t look down. If your mat texture has sharp peaks or deep gaps, someone will catch a toe. Then you’re writing an incident report. Not fun.

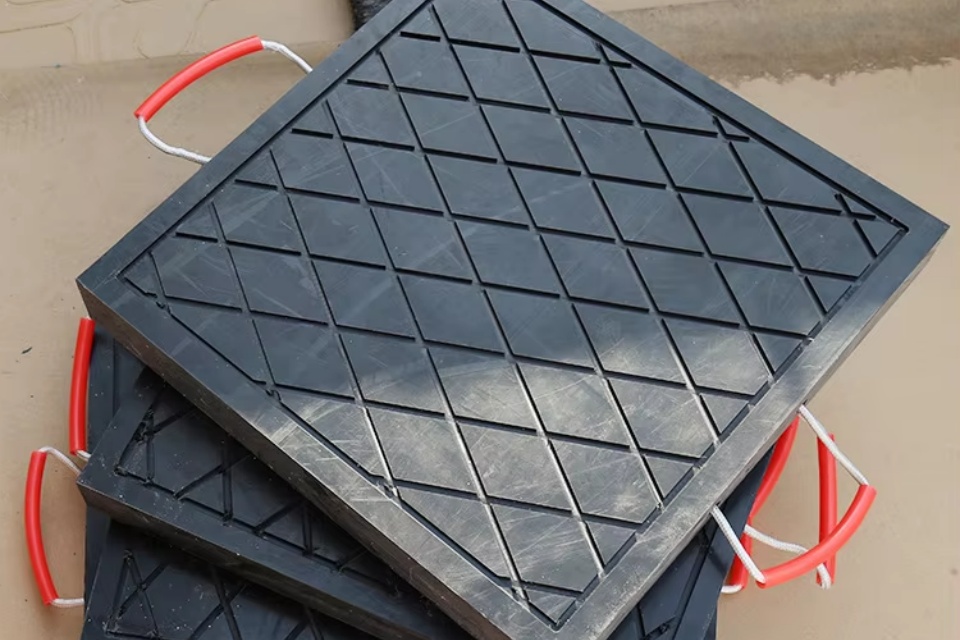

Dual-Sided Ground Protection Mats: Vehicle Side vs Pedestrian Side

This is why so many ground protection mats use two faces:

- One side: more aggressive vehicle traction

- Other side: flatter pedestrian traction

That design isn’t marketing fluff. It’s a real compromise that works in mixed traffic.

Here’s a decision table you can use when you spec texture:

| Traffic type | Best texture goal | Pattern direction | Common pain point | What to watch |

|---|---|---|---|---|

| Trucks / forklifts (tires) | Drain water + steady rolling | Grooves + repeating lugs | Wet spin while turning | Add channels, avoid “slick domes” |

| Skid steers / dozers (tracks) | Bite + self-clean in mud | Taller cleats + wider spacing | Mud packing + sideways slide | Keep gaps open, resist twist |

| Workers / visitors (walking) | Grip + low trip risk | Low-profile anti-slip | Slips on wet film | Avoid sharp peaks, keep cleanup simple |

If you only run tires, you can bias toward smoother drainage patterns. If you run tracks all day, go more aggressive. If you have both plus foot traffic, dual-sided mats are usually the least drama.

UHMWPE and HDPE: Material Behavior Still Matters

Texture helps, but the polymer matters too. HDPE and UHMWPE can both support tough outdoor work, yet they behave differently under wear, impact, and sliding.

- HDPE often shows up in ground mats because it’s stiff enough to spread load and hold shape.

- UHMWPE shines when you need serious abrasion resistance and low-friction sliding in harsh contact zones.

That “low-friction, high-wear” story shows up in bulk material handling. You can see the same thinking in coal flow control parts, where the goal is to reduce hang-ups and wear. If you deal with flow headaches, take a look at our coal bunker limit plates (no hype, just hard-use parts):

coal bunker limit plates

And in marine work, UHMWPE fender pads help with sliding contact and impact at berths. That’s a different scene, but it’s still friction management—just on a dock instead of a muddy road:

UHMWPE fender pads

Low friction vs grip (yes, both can be true)

People mix this up: “If UHMWPE is low friction, won’t it be slippery?”

Not always. Material friction and surface texture work together. You can build a surface that:

- Slides well where you want it (like against steel, rubber fenders, or chutes)

- Still provides traction where you need it (through macrotexture design)

It’s not magic. It’s just smart pattern + right polymer grade.

Field Checklist: Pick a Texture Without Overthinking It

If you want a fast rule set, use this:

- Is it mostly wet? Prioritize drainage grooves and open channels.

- Is it mostly mud? Space the lugs so mud can escape (or you’ll polish it smooth).

- Is it mostly tracks? Add cleat height and resist twist at seams.

- Is it mostly walking? Keep the profile lower and consistent. Reduce trip edges.

- Mixed traffic? Choose dual-sided, then train crews which side faces up.

Also, don’t ignore layout. Even the best pattern fails if mats float, rock, or gap open.

OEM/ODM Texture Work: Where “Good Enough” Usually Fails

If you buy mats in volume, you already know this: two mats can look the same and behave totally different.

That’s why OEM/ODM matters. At High-Performance Engineering Plastic Products Manufacturer, we support:

- Custom surface textures and thickness targets

- Bulk wholesale programs for contractors and distributors

- Sample lead times and stable production planning

- Fast response when the field throws you surprises

And yeah, sometimes you want rubber + plastic in one project. Dongxing Rubber can support rubber-side needs, while we match UHMWPE/HDPE sheet parts around the full system. It keeps sourcing simpler, and it helps you stop juggling too many factories.

Closing thought

Grip isn’t a single knob you turn up. It’s a match between texture scale, traffic type, and the mess on the ground. Get that match right, and crews move faster with fewer “whoa” moments. Get it wrong, and somebody will say, “These mats are slippery,” even when the real problem is the wrong pattern for the job.