-

Tian Dong Industrial Park, Decheng District Economic and Technological Development Zone, Dezhou City

Machining UHMWPE Cleanly: Cutting, Drilling, Tapping, Deburring Tips

You want clean parts, tight fits, and zero fuzzy edges. UHMWPE can do that. But it won’t forgive heat, dull tools, or timid feeds. Let’s walk through what actually works—on the saw, mill, drill, tap, and deburr bench—so your parts look clean and run right.

Quick note: At Dongxing Rubber, we make and supply UHMWPE & HDPE sheets, pads, and custom parts for OEM/ODM buyers. If you need ice-sport gear, check our Hockey Practice Shooting Pads as a real-world machining use case.

Table of Contents

Why UHMWPE Machining Feels Tricky (UHMWPE machining challenges)

UHMWPE is tough, slick, and heat-sensitive. It doesn’t break chips like metals. It smears when hot, springs back a little after cutting, and loves to make “stringers.” So we keep three rules in mind:

- Control heat. Lower surface speed, stronger feed, sharp tools, steady chip flow.

- Cut, don’t rub. Dull tools or feather-light feeds only polish and melt.

- Stabilize the part. Rigid workholding and let parts cool before final check.

(Yes, this material will “relax” after you take it off the vise.)

Cutting UHMWPE: Saws and Milling (cutting UHMWPE, milling UHMWPE)

Saws: Pick a coarse-tooth blade. Fine teeth rub and heat up, then you see white edges and melt marks. Keep a steady feed so the teeth bite, not burn. Air blast or light coolant helps a lot.

Milling: Use sharp HSS or carbide with positive rake. Try climb milling so the tool slices, not plows. Keep surface speed modest, but don’t baby the feed—make the tool work. If chips get long and stringy, pause to clear them or use a chipbreaker-style insert profile.

Drilling UHMWPE: Step Drilling and Breakout Control (drilling UHMWPE)

UHMWPE loves to grab at the exit. To avoid the hairy edge:

- Step it up. For large holes, drill in steps. That keeps heat down and keeps the drill tracking.

- Thin web / low helix drills. These can cut without pulling so hard on the exit side.

- Slow down at breakthrough. Ease the last millimeter. Use a backer board if the part is thin.

- Deburr right away. A tiny hand-chamfer on both sides prevents stringers from re-forming.

If you’re drilling holes that will be tapped later, remember: UHMWPE can “spring back” a tad. Your pilot may need to be a touch larger than a metal chart suggests. Don’t go wild—just allow for that elastic memory.

Tapping UHMWPE: Thread Forming vs Cutting (tapping UHMWPE)

Both work, but they behave different:

- Form taps (roll taps). Zero chips, stronger threads in ductile plastics, nice finish. Use proper lubricant. Keep RPM low, advance in short strokes if your machine allows, then back out to release any torque.

- Cut taps. Use a sharp, open-flute design and frequent chip clearing. Coarse pitch threads often hold better in UHMWPE than very fine pitch.

Tip: If the tap feels sticky on entry, your pilot hole is undersize for this material. UHMWPE’s elastic recovery can “close” holes a tiny bit. Open the pilot a whisper and try again.

Deburring UHMWPE: Clean Edges Without Heat (deburring UHMWPE)

Skip the heavy buffing wheel. Heat is the enemy. Keep it simple:

- Hand scraper / fresh blade to kiss off the burr in one controlled pass.

- Light abrasive (very fine grit) by hand, short strokes.

- Inside edges: a small boring bar or countersink, barely touching, works wonders.

- Don’t over-polish. If you press hard and heat up, the edge gets glossy then curls again. Looks ugly and not dimension-true.

Workholding & Dimensional Stability (workholding UHMWPE, dimensional control)

UHMWPE is stiff for a plastic, but it’s still a plastic. It will flex and rebound.

- Rigid clamping. Use vacuum tables, soft jaws, or broad clamps to spread load. Avoid point-pressure that dents the surface.

- Support thin panels. Put a spoilboard/backer under sheet cuts.

- Cool-down check. Measure after the part returns to room temp. If you inspect hot-off-the-tool, you might chase ghosts.

- Leave finishing stock. Rough, let it cool, then take a clean skim pass.

This matters when you machine sport gear like hockey practice shooting pads—they need flatness and crisp edges so sticks glide nice.

Coolant, Chip Control, and Surface Finish (cooling UHMWPE, surface finish UHMWPE)

- Air blast keeps chips moving and reduces smearing.

- Mist or light coolant can help, but don’t flood so hard you hydroplane the tool.

- Chip control: break long chips by stepping tools, using chipbreaker inserts, or pausing to clear.

- Surface finish improves when the tool is sharp and the feed is honest. A “rubby” pass produces that chalky look. No good.

Practical Settings You Can Start From (qualitative only)

Use this for direction, then tune on your machine. No hard numbers here.

| Operation | Tooling & Geometry | Relative Speed | Relative Feed | Coolant / Air | Typical Defect | First Fix |

|---|---|---|---|---|---|---|

| Sawing | Coarse-tooth blade, sharp | Low-Medium | Steady | Air or light coolant | Melted edge, white smear | Coarser teeth, more feed |

| Face/Edge Milling | Sharp HSS/Carbide, positive rake, climb | Low | Medium-High | Air first, mist if needed | Fuzzy edge, strings | Increase feed, sharpen tool |

| Pocketing | 2- or 3-flute end mill, chip-friendly | Low | Medium | Air | Bird-nest chips | Peck pattern, chipbreaker |

| Drilling (small) | Low-helix, thin web drill | Low | Medium | Air, backer | Hairy exit | Slow at breakthrough |

| Drilling (large) | Step drilling (2–3 steps) | Low | Medium | Air/mist | Oversize, heat swell | More steps, clear chips |

| Tapping (form) | Roll tap, coarse pitch | Low | Controlled | Lube | High torque | Enlarge pilot slightly |

| Tapping (cut) | Sharp open-flute, coarse | Low | Controlled | Lube | Stringy chips | Frequent reverse to clear |

| Deburring | Hand scraper, fine paper | — | — | Dry, cool | Re-burr after polish | One-pass scrape, lighter touch |

If a pass “looks shiny but sticky,” you’re rubbing. If chips look like spaghetti, your feed is too shy or tool isn’t breaking them. Dont ignore the smell—hot plastic tells on you.

Field Scenarios You’ll Recognize (use cases with UHMWPE)

Ice & sport gear: Edges must be smooth for stick glide. For Hockey Practice Shooting Pads, we keep cuts cool and deburr with a hand scraper so the puck won’t catch. Thin pads need a backer during drilling to prevent hairy exits. Explore more in our ice rink products lineup.

Ground protection & road mats: Big panels, long cuts. Coarse-tooth saws and climb passes keep productivity up. Parts are measured after cool-down; we often leave a tiny finishing pass for flatness. See our ground protection road mats for real field use.

Engineered sheets for OEM: Threaded inserts? We prefer formed threads in UHMWPE when the design allows. If you must cut threads, choose coarse pitch and lube. For repeat runs, we document the “chip-look” so operators can spot drift fast—real shop trick, works good. We stock UHMWPE sheets, HDPE sheets, and MG engineering plastic sheets to match different builds.

Buying and Production Notes (for OEM/ODM, wholesale)

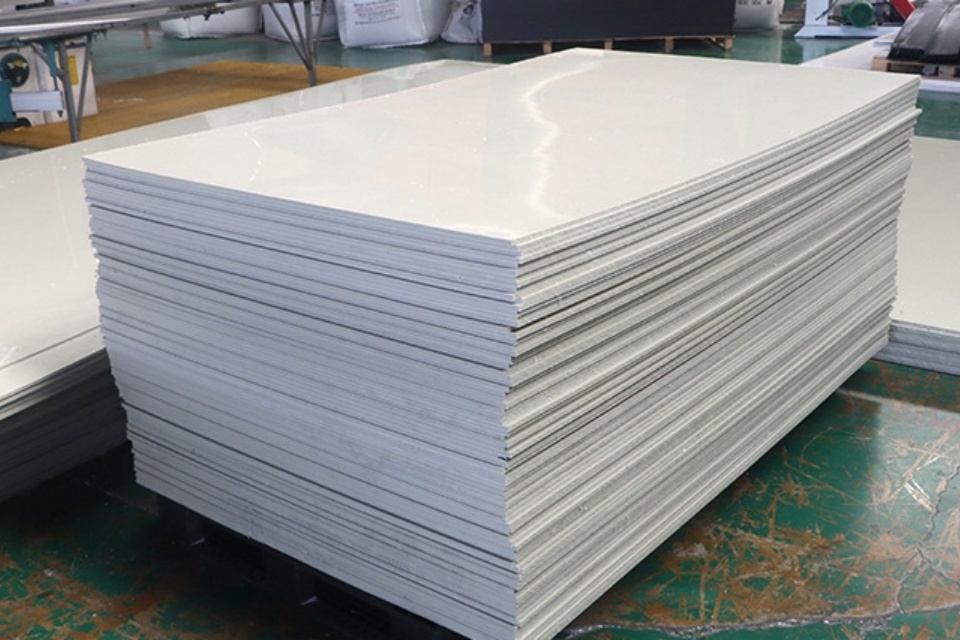

- Material options: We supply UHMWPE & HDPE sheets, pads, and custom shapes. If you need specific slip, color, or wear properties, we can tailor it.

- Services: Customization, bulk wholesale, OEM/ODM. Quick sampling and batch production. 24-hour response—talk to us, we’ll spec the cut plan with you. For one-stop project support, see our OEM/ODM services.

- Consistency: For repeat orders, we lock in tool style and pass strategy (no guessing next time). That’s how we keep your edges and holes looking the same, lot to lot.

Troubleshooting Cheat Sheet (quick fixes you’ll use tomorrow)

- Edge looks chalky / white: Too hot → drop speed, raise feed, sharpen tool, add air.

- Strings everywhere: Increase feed, use chipbreaker geometry, step the cut.

- Tap is hard to turn: Pilot slightly small for UHMWPE recovery → open it a hair; use form tap if possible.

- Hairy exit on holes: Slow at breakthrough, add backer board, micro-chamfer both sides.

- Part out-of-flat after cut: Let it cool, then skim. Support better during machining.

Why Work With Dongxing Rubber

You want clean cuts, tidy threads, and repeatable parts. We already run these flows daily for ice rinks, ground mats, and engineered sheets. We speak the shop language—chip welding, spring-back, angel-hair, all that—and we tune for your machines, not a textbook. If you’re building training gear like hockey practice shooting pads or you need OEM runs, ping us and we’ll share a starter process sheet for your line.

Final Take

Cut, don’t rub. Keep it cool. Hold it solid. Measure after it rests. Do those four, and your UHMWPE parts will look clean and run clean. This part look good, ya?