-

Tian Dong Industrial Park, Decheng District Economic and Technological Development Zone, Dezhou City

Life-Cycle Costs: UHMWPE Fender Pads In Busy Terminals

You can buy a fender pad cheap. You can also buy it smart.

In a busy terminal, the “life-cycle cost” isn’t just what you pay on day one. It’s the inspection time, the swap-out hassle, the downtime risk, and that ugly moment when a ship’s sliding and your face pad is already half gone.

If you run a berth that never sleeps, you already know the pain points:

- Tight berthing windows.

- Crew doing “quick fixes” that turn into repeat work.

- Spare parts missing when you need them most.

- Hardware that looks fine… until it isn’t.

Let’s talk about how UHMWPE fender pads can reduce those headaches over the long haul, without getting lost in cost math.

Table of Contents

Life-Cycle Cost Drivers In Marine Fender Systems

Life-cycle cost (LCC) is basically total cost of ownership, but with saltwater, steel, and schedules.

Inspection Labor And Access Time

If your fenders sit in awkward spots, your inspection becomes slow. Slow means you skip steps. Skipped steps means surprise damage later.

Busy terminals don’t lose money only from broken parts. They lose money from time. Time is the real monster here.

Downtime Risk During Berthing Windows

A pad replacement that takes “a little longer than planned” can wreck a whole shift. Then ops team gets grumpy, and everyone start blaming everyone. Happens a lot.

Here’s the key idea: design + material can reduce how often you touch the system, and how fast you can fix it when you must.

UHMWPE Fender Facing Pads And Wear Behavior

UHMWPE sits in a sweet spot for fender facing: low friction feel, strong abrasion resistance, and high impact toughness.

Low Friction Sliding And Reduced Scuff Damage

When a vessel makes contact, it doesn’t always hit straight. You get micro-sliding. You get yaw. You get rub points.

A stable, low-friction facing helps reduce:

- Paint scuffs on hulls

- Local heat from rubbing

- “grabby” contact that twists chains and frames

That means fewer complaint calls. Less finger-pointing too.

Abrasion Resistance In High-Cycle Berths

If your berth handles frequent calls, your pad sees high cycle count. Think tug assist, short stays, constant contact.

A good UHMWPE pad doesn’t magically last forever. But it tends to wear slowly and predictably when thickness and fastening are right.

Repair vs Replace: Why Spare Pads Matter More Than You Think

Here’s a blunt truth: many UHMWPE face pads don’t “repair” well once they’re cracked, missing chunks, or heavily grooved. In real terminals, you usually replace.

So your LCC depends on two things:

- How often replacement happens

- How smooth replacement goes

Missing Pads Create Cascading Wear

When one pad goes missing, the neighbor pads often take extra rubbing. Metal parts may start seeing contact. Then your “small issue” grows legs and starts running.

Spare Parts And Response Speed

If you keep a small spare set on site, you avoid long waiting. If you don’t, you gamble with downtime.

And yeah, supply chain can be messy. That’s why OEM/ODM and bulk planning matters, even if you don’t love procurement meetings.

Preventive Maintenance Intervals For Fender Panels, Chains, And Fasteners

You don’t need fancy words. You need a schedule you actually follow.

Recommended Maintenance Rhythm Table

| Item | Routine Visual Check | Planned Service Window | Major Overhaul Window |

|---|---|---|---|

| Rubber fender body | Annual | Every few years | Long-cycle overhaul |

| Steel panel / frame | Annual | Every few years | Long-cycle overhaul |

| UHMWPE face pad | Annual | Every few years | Long-cycle overhaul |

| Anchors / bolts | Annual | Every few years | Long-cycle overhaul |

| Chains / shackles | Annual | More frequent | Shorter overhaul cycle |

No, this table isn’t “perfect.” But it’s realistic. Chains and hardware often drive more repeat work than people expect, especially in rough berths.

What You Actually Look For On UHMWPE Pads

- Deep grooves (uneven wear)

- Loose fasteners or oval holes

- Edge chipping from misalignment

- Pads “walking” or shifting on the frame

If you see these early, you can fix it before it becomes a shut-down job.

Designing For Maintainability: Quick Swap, Safe Work, Less Drama

In LCC talk, maintainability is huge. If your techs hate the job, it won’t get done on time. Simple.

Fastener Layout And Countersink Quality

Bad countersinks create stress points. Loose hardware creates movement. Movement creates more wear. It’s like a little wobble that turns into a big problem.

A good build usually includes:

- Correct countersink angle and depth

- Controlled torque practice

- Anti-seize where it makes sense

- Backing support to avoid localized crushing

Pad Thickness And Real-World Wear Allowance

Thin pads can work, but they burn through quicker in high cycle berths. Thick pads can last longer, but they must sit flat and mount right. Otherwise you just waste material.

Your goal is boring: stable contact, predictable wear, easy service.

LCC Without Cost Numbers: A Practical “Pressure Map” For Decision-Making

You asked for no cost math. That’s fine. You can still compare options using a simple qualitative map.

LCC Pressure Map Table

| LCC Factor | Busy Terminal Impact | What Helps Most |

|---|---|---|

| Downtime sensitivity | Very High | Faster replacement design, stocked spares |

| Inspection access | High | Clear access points, simple checklists |

| Wear rate under sliding | High | Correct UHMWPE grade, proper thickness |

| Hardware loosening | Medium–High | Good fasteners, torque control, locking method |

| Corrosion around mounts | Medium–High | Coatings, isolation, smart hardware choice |

| “Small defect grows fast” risk | High | Early inspection + quick fix mindset |

This is the table ops people actually use. It keeps the conversation real.

Real-World Scenarios: What Busy Terminals See (And What You Can Do)

Scenario 1: “We Keep Replacing Pads In The Same Spot”

That usually means misalignment, uneven load, or hardware movement. Don’t just swap pad and walk away. Fix root cause, or you’re paying twice in labor. And you’ll feel it.

Scenario 2: “We Can’t Shut Down This Berth”

Then you need two things: spare pads on hand, and a replacement method that doesn’t require circus-level rigging.

This is where custom fabrication helps. If you need specific hole patterns, bevels, or pad sizes, OEM/ODM can save you future headaches.

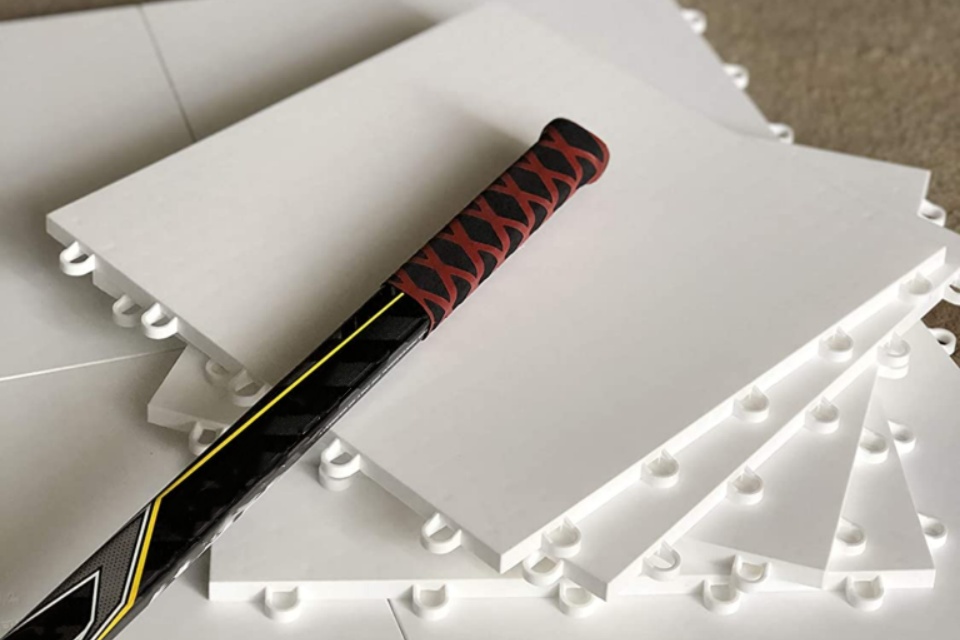

Scenario 3: “We Also Sell Wear Panels For Other High-Abrasion Surfaces”

This is a fun parallel. A busy berth beats up fender pads like a hockey player beats up practice gear.

If you’ve ever used a Hockey Practice Shooting Pads surface, you know the deal: constant impact, constant sliding, constant abrasion. You don’t buy it to look pretty. You buy it to take hits and stay flat.

Same mindset with marine pads. You want a wear surface that stays stable under abuse.

And if you’ve worked with Ice Synthetic Panels before, you’ve seen how surface finish and wear pattern matter. Bad surface behavior becomes user complaints fast. In terminals, “user complaints” look like damaged coatings and angry emails.

Where “Dongxing Rubber” Fits In A Practical Fender Stack

Most terminals don’t run “plastic only” fender systems. They run a full stack:

- Rubber fender body for energy absorption

- Steel panel for load spread

- UHMWPE facing for sliding + wear

In some builds, teams pair UHMWPE fender pads with rubber fenders supplied through partners like Dongxing Rubber. That combo can make the system easier to manage over time, because each layer does its job, no confusion.

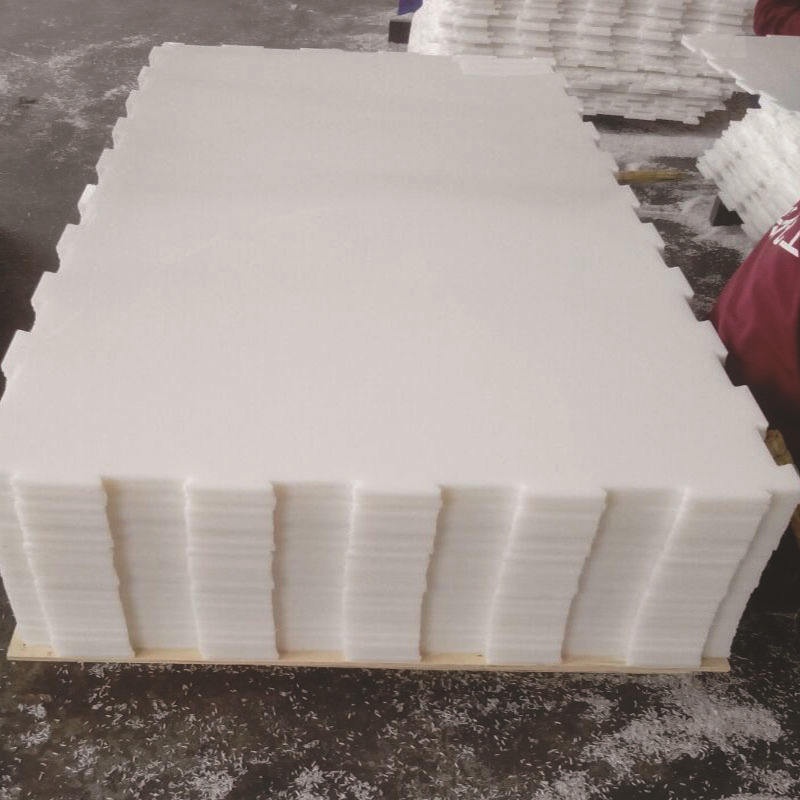

How Our Factory Approach Supports Lower Life-Cycle Headaches

We’re a High-Performance Engineering Plastic Products Manufacturer. We focus on UHMWPE and related plastics for harsh working places.

Here’s what busy terminals usually ask for:

- Custom sizes, hole patterns, chamfers (OEM/ODM)

- Bulk wholesale supply for multi-berth standardization

- Stable lead times for planned shutdown windows

We support that with practical service expectations:

- Samples in 3–15 days

- Production in 3–20 days

- 24-hour response

And yeah, sometimes you just need it fast. We get it.

Quick Checklist Before You Choose Or Re-Spec UHMWPE Fender Pads

| Question | If “No” | What To Change |

|---|---|---|

| Can your team inspect pads safely and quickly? | Inspections get skipped | Improve access + simple check routine |

| Do you have spare pads on site? | Downtime risk jumps | Stock a minimum spare set |

| Does hardware stay tight over time? | Pads start moving | Upgrade fastener plan + torque habit |

| Is wear happening evenly? | One spot fails early | Check alignment + load spread |

| Can you swap pads in a short window? | Shutdown gets longer | Design for quick replacement |