-

Tian Dong Industrial Park, Decheng District Economic and Technological Development Zone, Dezhou City

Food-Contact Compliance for UHMWPE/HDPE Sheets: A Quick Checklist

If your UHMWPE or HDPE sheets will touch food, the bar is high—and rightly so. This quick, engineer-friendly checklist turns complex regulations into practical steps you can act on today.

Table of Contents

FDA 21 CFR 177.1520 compliance checklist

Confirm polymer category and intended use

Match your polyethylene grade and intended use to the correct olefin polymer provision in 21 CFR 177.1520. Keep the exact item number in your technical file along with a supplier letter of guarantee.

Verify additive clearances in 21 CFR Part 178

Antioxidants, stabilizers, slip agents, lubricants, antistats, and pigments must be authorized and used within stated limitations. Capture composition statements and batch usage levels.

Align with the Food Contact Notification framework

If an additive or condition of use is not already covered, document how it is authorized through an existing regulation or an FCN. If no additives are used, state that clearly in the file.

EU 10/2011 plastics regulation essentials

Check the Union List and specific migration limits

Confirm every monomer, additive, and processing aid is authorized and meets any specific migration limit or quantity restriction. Keep supplier references for each component.

Meet the overall migration limit

Plan testing to the 10 mg per square decimeter overall migration limit using the correct food simulants and worst-case time and temperature for your declared use.

Define conditions of use and test design

Link real-world conditions to laboratory tests. Declare food types, contact time and temperature, and reuse expectations. Choose simulants and test cycles that represent the worst credible case.

Material and formulation controls

Choose food-contact-appropriate resin

Confirm identity as UHMWPE or HDPE, viscosity or melt index class, and whether the resin is virgin. If recycled content is used for a market claim, ensure it is permitted for direct food contact and document the chain of custody.

Lock down additives, pigments, and colorants

For color packages and slip systems, confirm authorization and any SML limits. Store certificates of analysis, usage ranges, and pigment CI numbers where applicable.

Manufacturing and hygiene under GMP

Implement contamination controls and sanitation

Run to Good Manufacturing Practice. Segregate food-contact materials, implement clean changeovers, define rework rules, and document sanitation frequency and methods.

Control processing parameters that affect migration

Thickness, temperature history, cooling rate, and post-processing can influence extractables. Record critical parameters, acceptance ranges, and equipment settings to support repeatable compliance.

Testing and documentation package

Perform migration testing or conservative calculations

For EU supply, run overall and specific migration as needed. For the US, assemble a scientific basis that demonstrates compliance with the cited CFR sections, including worst-case migration modeling or supporting tests.

Issue an EU Declaration of Compliance

Identify the material, intended food types, contact time and temperature, and any multilayer details. Reference applicable legislation and attach a list of authorized substances where required.

Maintain traceability from resin to finished sheet

Tie resin lots, additives, pigments, and processing conditions to finished-sheet IDs. Archive test reports and supplier declarations for the statutory retention period.

Conditions of use and labeling

Define allowable temperatures and contact duration

State whether the sheet is for room-temperature contact, chilled storage, hot fill, or brief reheating. Note exclusions such as prolonged contact with high-fat foods at elevated temperatures if not supported by evidence.

Provide clear labeling and instructions

Place use conditions in customer specifications and labels. Include first-use washing guidance, sanitation compatibility, and reuse limits if applicable.

Rapid buyer’s checklist

- Polymer and use match 21 CFR 177.1520 and EU 10/2011

- All additives authorized and within limits

- EU overall migration ≤ 10 mg per square decimeter with SMLs met

- Conditions of use defined and backed by testing or rationale

- GMP and contamination controls documented

- Migration tests or conservative calculations on file

- EU Declaration of Compliance issued, US compliance statement available

- Full traceability from resin lot to shipment

- Labels and instructions reflect tested limits

Helpful UHMWPE and HDPE resources on our site

Explore materials, formats, and services that support compliant builds and clean documentation:

- Homepage

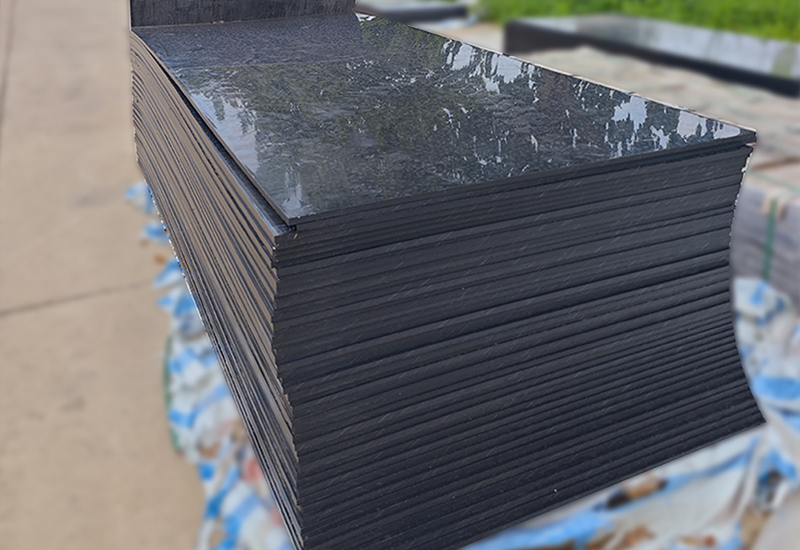

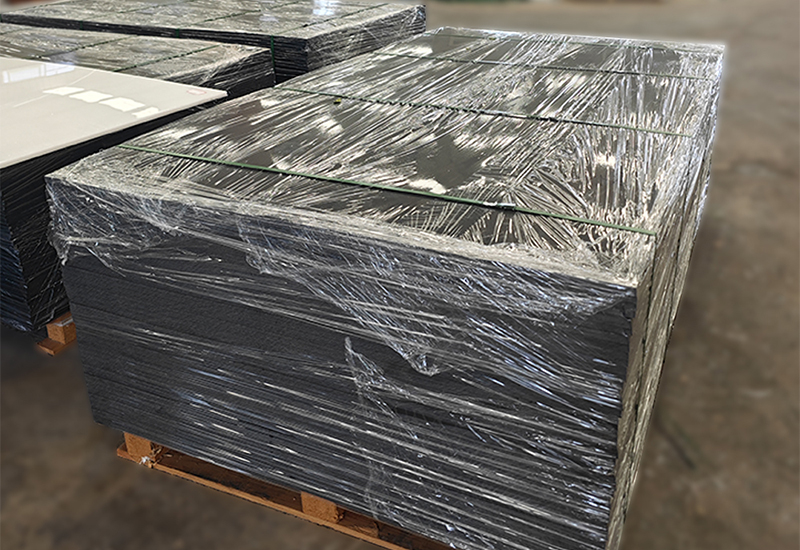

- UHMWPE sheets

- HDPE sheets

- UHMWPE and HDPE sheets and plates

- PP and PE products

- Products catalog

- Industries served

- OEM and ODM services

Engineer tip you can copy into your SOPs: build a living food-contact dossier per resin grade and thickness. When formulations, pigments, suppliers, or processing windows change, re-check the CFR and EU alignment, redo worst-case assessments, and update your Declaration of Compliance and customer claims.