-

Tian Dong Industrial Park, Decheng District Economic and Technological Development Zone, Dezhou City

OEM/ODM-Dienstleistungen

Wir bieten einen umfassenden Service für die OEM/ODM-Herstellung von Hochleistungs-Kunststoffprodukten. Mit globaler Erfahrung und integrierter Produktion liefern wir maßgeschneiderte Lösungen, die durch fundiertes technisches Fachwissen unterstützt werden - von der Materialauswahl bis zur abschließenden Qualitätskontrolle - und bei denen Innovation, Zuverlässigkeit und Wertigkeit im Vordergrund stehen.

Umfassendes Produktportfolio für verschiedene Branchen

Wir stellen eine breite Palette von UHMWPE-, HDPE- und anderen Polymerprodukten her, die den unterschiedlichsten industriellen und kommerziellen Anforderungen entsprechen. Dank dieser breiten Produktpalette können wir eine Vielzahl von Kunden - von der Schwerindustrie bis hin zu Sporteinrichtungen - mit gleicher Kompetenz bedienen. Unsere wichtigsten Produktlinien umfassen

Ingenieurwesen und technische Kunststoffe

Platten und Blätter aus ultrahochmolekularem Polyethylen (UHMWPE) und Polyethylen hoher Dichte (HDPE) (einschließlich Spezialtypen wie Bleibor-Polyethylen für den Strahlenschutz) sowie andere technische Kunststoffe wie Nylonplatten und PP/PE-Produkte. Diese Materialien werden in anspruchsvollen Anwendungen wie dem nuklearen und medizinischen Strahlenschutz, Komponenten für die Luft- und Raumfahrt und vielem mehr eingesetzt. Wir haben Standardgrößen auf Lager und bieten auch Zuschnitte oder CNC-gefertigte Teile nach Spezifikation an.

Bodenschutz & Industrielle Sicherheit

Hochbelastbarer Bodenschutz, leicht gemacht: Amphi-, Base-, Dura- und Quick-Matten für temporäre Straßen und Arbeitsplattformen sowie Kranauslegerplatten, Kohlebunkerbegrenzungsplatten und UHMWPE-Kotflügelplatten. Sicherer Zugang, solide Traktion und Oberflächenschutz für Bau, Energie, Bergbau und Veranstaltungen.

Sport- und Freizeitprodukte

Ein spezielles Sortiment an Komponenten für Eisbahnen und Sportarenen, einschließlich kompletter Eishockeybandensysteme, Floorballbanden, Kunsteisplatten und Eishockey-Übungsschiessmatten. Wir liefern langlebige, stoßfeste Platten und Paneele für Eishockeybahnen und andere Sporteinrichtungen, die für intensive Nutzung und raue Witterung ausgelegt sind. (Wir bieten sogar “Remote Ice”-Eisbahnprodukte für mobile oder temporäre Eisbahnen an). Arenen und Trainingszentren vertrauen auf diese Lösungen wegen ihrer Qualität und einfachen Installation.

Kundenspezifisch geformte und gefertigte Teile

Kundenspezifisch gefertigte Kunststoffe, durchgängig: strahlenabschirmende Bleibor-PE-Platten, Verschleißauskleidungen (Kohlebunker, Schurren), maschinell bearbeitete Zahnräder/Walzen und mehr aus UHMWPE, HDPE und Polypropylen. Gebaut für das Baugewerbe, die Logistik, die Schifffahrt, den Sport, den Energiesektor und das Gesundheitswesen - von industrieller Stärke bis hin zu Spezialsportarten.

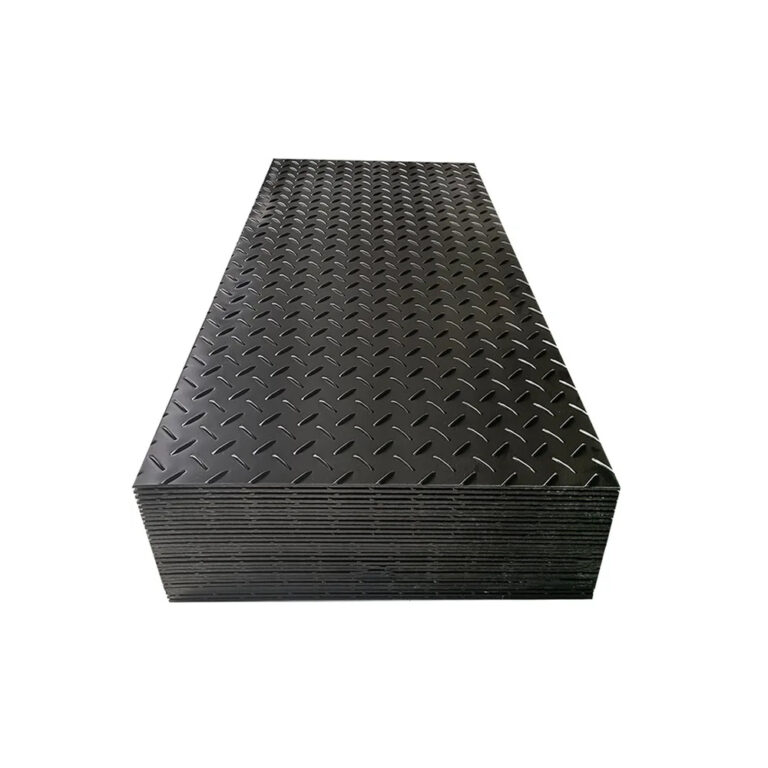

Heavy Duty Track Mats Hdpe Plastic Sheet Schutz Matte

Hochbelastbare HDPE-Raupenmatten bieten dauerhaften Bodenschutz für schwere Maschinen und Fahrzeuge. Mit ihren rutschfesten Oberflächen und ihrer hohen Belastbarkeit sind sie ideal für temporäre Straßen, Arbeitsbühnen und Baustellen und gewährleisten Stabilität auf weichem oder unebenem Boden.

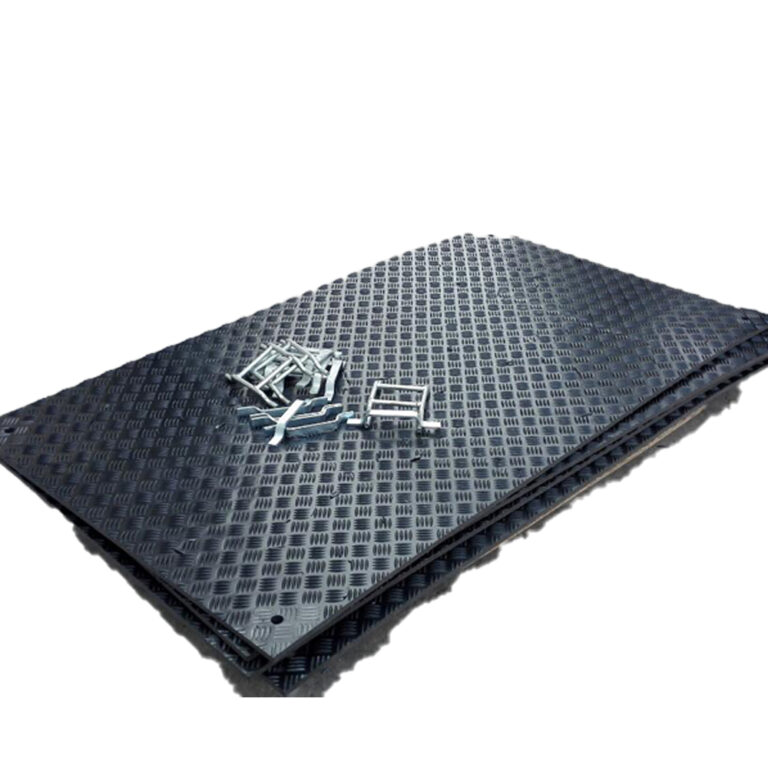

Komposit-Kunststoffmatte Schwere Ausrüstung Amphi Mat Großhändler

Wir sind Großhändler für Hochleistungs-Kunststoffmatten aus Verbundwerkstoff, auch bekannt als Amphibienmatten, für schweres Gerät. Diese langlebigen Matten verfügen über ein Rautenmuster für hervorragende Traktion, Lastverteilung und Oberflächenschutz. Ideal für temporäre Fahrbahnen und Bodenschutz,...

Kran Ausleger Pads UHMWPE Stabilisator Platten Lieferanten China

UHMWPE-Kranabstützungen verteilen die Last des Hebers, um den Boden zu schützen und ein Absinken zu verhindern. Leicht, nicht leitend, korrosionsbeständig. Anti-Rutsch-Oberfläche, abgeschrägte Kanten, Tragegriffe. Größen 300-1200 mm, 20-100 mm dick, Zuschnitt nach Maß. Ideal für Kräne und Aufzüge. Lieferant aus China.

Vollständige Anpassung & OEM-Unterstützung

Sie haben ein Bild in Ihrem Kopf. Unsere Aufgabe ist es, es in die Realität umzusetzen. Als Ihr OEM/ODM-Partner passen wir jedes Teil an Ihre Spezifikationen und Ihre Marke an - und helfen bei jedem Schritt, damit nichts in der Übersetzung verloren geht. Unsere Anpassungsoptionen umfassen:

Design & Spezifikationen

Wir können völlig neue Entwürfe erstellen oder bestehende Entwürfe an Ihre Anforderungen anpassen. Stellen Sie uns Ihre CAD-Zeichnungen, technischen Diagramme oder sogar Musterteile zur Verfügung, und unser Ingenieurteam wird das Produkt entsprechend entwickeln. Wir sind in der Lage, kundenspezifische Abmessungen (Länge, Breite, Dicke) und Formen zu realisieren. So können beispielsweise unsere UHMWPE-Kranauslegerplatten in verschiedenen Größen und Dicken hergestellt werden, um die spezifische Lastverteilung Ihrer Ausrüstung sicher zu bewältigen. Selbst komplexe Geometrien oder gebohrte Muster können mit unseren CNC-Bearbeitungszentren für Präzisionsschnitte realisiert werden.

Materialauswahl & Modifikation

Sie haben ein Ziel vor Augen? Informieren Sie sich über unsere Materialien und Qualitäten, oder lassen Sie sich von unseren Experten beraten, welches Material am besten für Ihre Konstruktion geeignet ist. Wir arbeiten mit UHMWPE, HDPE, PP, Nylon und mehr - und wir können jedes Material so abstimmen, dass es die richtige Mischung aus Festigkeit, Sicherheit und Schutz bietet. Fügen Sie UV-Inhibitoren für das Leben im Freien, antistatische Pakete für sensible Bereiche oder Bor für den Schutz vor Neutronenstrahlung hinzu. Unsere Experten stellen sicher, dass das von uns gelieferte Polymer oder der Verbundwerkstoff Ihre mechanischen, thermischen und chemischen Anforderungen erfüllt. Unterstützt durch Testdaten und klare Dokumentation.

Oberfläche, Farbe & Branding

Wir bieten eine Vielzahl von Veredelungen an und können auch das Aussehen Ihrer Produkte individuell gestalten. Dazu gehören Oberflächenstrukturen (z. B. rutschfeste Laufflächen für Bodenmatten), glatte oder abgeschrägte Kanten für Sicherheitsmatten und eine breite Palette von Farben. Benötigen Sie gut sichtbare Optionen wie Sicherheitsgelb oder Orange? Das ist kein Problem. Wir können die Farbe auch an Ihre Marke anpassen. Für Erstausrüster (OEMs) bieten wir Private Labeling an - Ihr Logo kann aufgedruckt oder eingraviert werden - und wir bieten individuelle Verpackungen, damit Ihre Produkte verkaufsfertig und perfekt auf Ihre Marke abgestimmt sind.

Vom Prototyp zur Produktion

Wir sind mehr als nur ein Hersteller - wir sind ein Entwicklungspartner. Wenn Sie sich in einem frühen Entwicklungsstadium befinden, erstellen wir schnell die ersten Teile und helfen Ihnen, Ihr Design durch echtes Feedback zu gestalten. Sobald es fertig ist, skalieren wir mit Ihnen - nahtlos und mit einer Qualität, auf die Sie sich verlassen können. Egal, ob es sich um ein Einzelteil oder eine komplette Produktionsserie handelt, wir behandeln es mit der gleichen Sorgfalt. Denn für uns ist jede Phase wichtig. Vom ersten Versuch bis zur vollständigen Markteinführung sorgen wir dafür, dass Ihr Produkt in die Welt hinausgeht - fertig und richtig.

Maßgeschneiderte Uhmwpe Pom Hdpe Nylon Polyethylen Pom Blatt

Kundenspezifische UHMWPE-, POM-, HDPE-, Nylon- und Polyethylenplatten bieten eine hervorragende Verschleißfestigkeit, Schlagzähigkeit und chemische Stabilität. Sie sind leicht zu bearbeiten und eignen sich ideal für Zahnräder, Lager, Auskleidungen und industrielle Komponenten in anspruchsvollen Umgebungen.

Quick Mat Heavy-Duty Bodenschutz Straßenmatte Lieferant

Quick Mat HDPE-Bodenschutzmatten mit Diamantprofil schaffen stabile Zufahrtswege und Arbeitsflächen. Sie sind rutschfest, wendbar und verkettbar, verteilen die Last, schützen die Grasnarbe und sind chemikalienbeständig. Wiederverwendbar, leicht, einfach zu reinigen - ideal für Lkw, Kräne, Versorgungsunternehmen und Veranstaltungen.

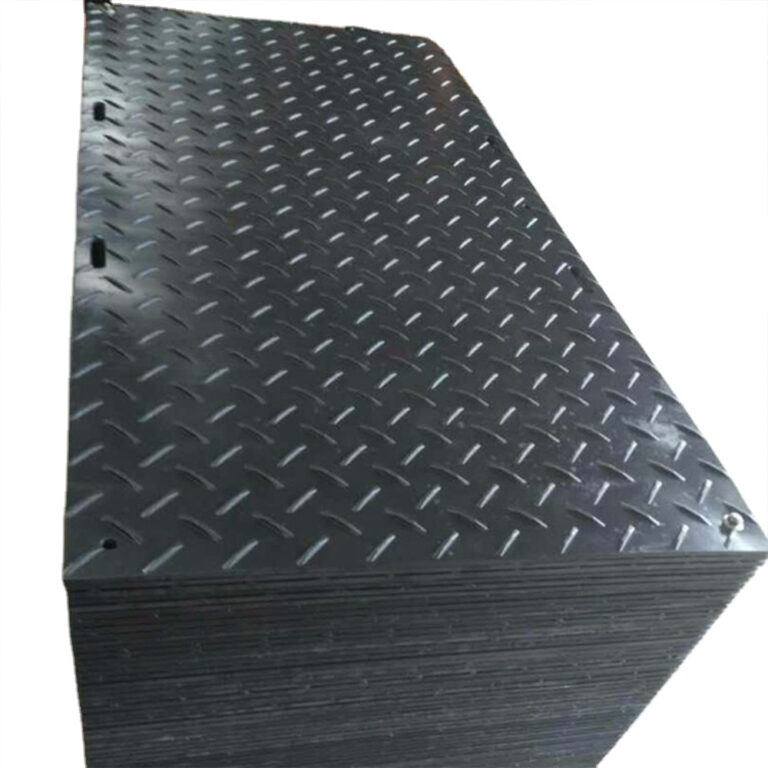

Leichte HDPE Bodenschutzmatten mit Bodenhaftung

Die leichten HDPE-Bodenschutzmatten bieten eine stabile, rutschfeste Unterlage für Fahrzeuge und Geräte. Sie sind langlebig, wiederverwendbar und leicht zu verlegen und verhindern Bodenschäden auf Baustellen, Veranstaltungen und in weichem Gelände. Ideal für temporäre Fahrbahnen und Arbeitsbereiche.

Fortschrittliche technische Fähigkeiten und Materialkenntnisse

Unsere OEM/ODM-Arbeit wird von echtem, praktischem Fachwissen getragen. Wir haben beträchtliche Ressourcen in modernste Ausrüstung, erfahrene Mitarbeiter und bewährte Qualitätssysteme investiert, damit wir anspruchsvolle Spezifikationen ohne Kompromisse erfüllen können. Unsere Anlagen arbeiten mit fortschrittlichen Werkzeugen, die für Hochleistungskunststoffe entwickelt wurden und bei jedem Auftrag enge Toleranzen, wiederholbare Ergebnisse und eine reibungslose, effiziente Produktion gewährleisten. Mit Sorgfalt!!

Hochmoderne Ausrüstungen

Je nach Produkt setzen wir eine Reihe von Produktionstechniken ein - darunter Extrusion und Formpressen für Platten und Paneele, CNC-Fräsen und -Bearbeiten für kundenspezifische Formen, Spritzguss für komplexe Teile und Fertigung/Montage für Verbundstrukturen. Mit dieser vielfältigen Ausstattung können wir alles herstellen, von großformatigen HDPE-Platten bis hin zu kompliziert bearbeiteten Komponenten. Alle Prozesse werden unter strenger Kontrolle durchgeführt, um genaue Abmessungen und eine hervorragende Oberflächenqualität zu erzielen.

Erfahrenes Ingenieurteam

Unser technisches Team besteht aus erfahrenen Ingenieuren, Materialexperten und praktischen Technikern, die die Kunststofftechnik leben und anwenden. Gemeinsam verfügen sie über jahrzehntelange Erfahrung in der Kunststoffherstellung. So erhalten Sie bei jedem OEM/ODM-Projekt kreative Problemlösungen mit präziser, zuverlässiger Technik. Wir helfen bei der Verfeinerung von Designs für eine einfachere Produktion, empfehlen intelligentere Materialien und stellen sicher, dass Ihr Produkt die versprochene Leistung erbringt. Dieser technische Schwerpunkt zahlt sich besonders bei Programmen aus, die neue Ideen oder die strikte Einhaltung von Industriestandards erfordern. Wir bleiben von der Konzeptüberprüfung bis hin zu den Testläufen und der Produktionsaufnahme dabei.

Materialwissenschaftliche Kompetenz

Bei der Arbeit mit technischen Kunststoffen geht es um mehr als nur die Auswahl eines Materials - es geht darum, wirklich zu wissen, wie sich jedes einzelne verhält. Wir haben Jahre damit verbracht, uns mit jeder unserer Optionen vertraut zu machen: von UHMWPE, das von selbst gleitet und Stöße abfängt, über die robuste Haltbarkeit von Nylon bis hin zur unschlagbaren Chemikalienbeständigkeit von PP. Mehr noch, unser Team liebt die Herausforderung: Wir helfen Ihnen bei der Auswahl des perfekten Basisharzes oder mischen sogar ein maßgeschneidertes Compound - und fügen flammhemmende oder festigkeitssteigernde Bestandteile hinzu, wann immer Sie sie brauchen. Dieses umfassende Material-Know-how bedeutet, dass Ihre Teile nicht nur passen, sondern auch allem standhalten, was Sie ihnen zumuten - ob Druckbelastung, abrasiver Verschleiß, sengende Hitze oder aggressive Chemikalien.

Qualitätssicherung

Wir legen bei jedem Schritt großen Wert auf Qualität. Unsere Produktionslinien laufen unter ISO 9001 (und anderen Branchenzertifizierungen), damit wir es gleich beim ersten Mal richtig machen. Auf dem Weg dorthin überprüfen wir die Abmessungen bis auf den Mikrometer genau, führen Belastungstests an kritischen Teilen wie Kranauflagen durch und verifizieren die Materialeigenschaften, wann immer es nötig ist. Bevor irgendetwas unser Haus verlässt, wird es einer Endkontrolle unterzogen, um sicherzustellen, dass Ihre OEM-Komponenten jedes Mal ins Schwarze treffen. Wir sind nicht nur bestrebt, Ihre Spezifikationen zu erfüllen, sondern Sie mit einer Leistung zu überraschen, die weit darüber hinausgeht.

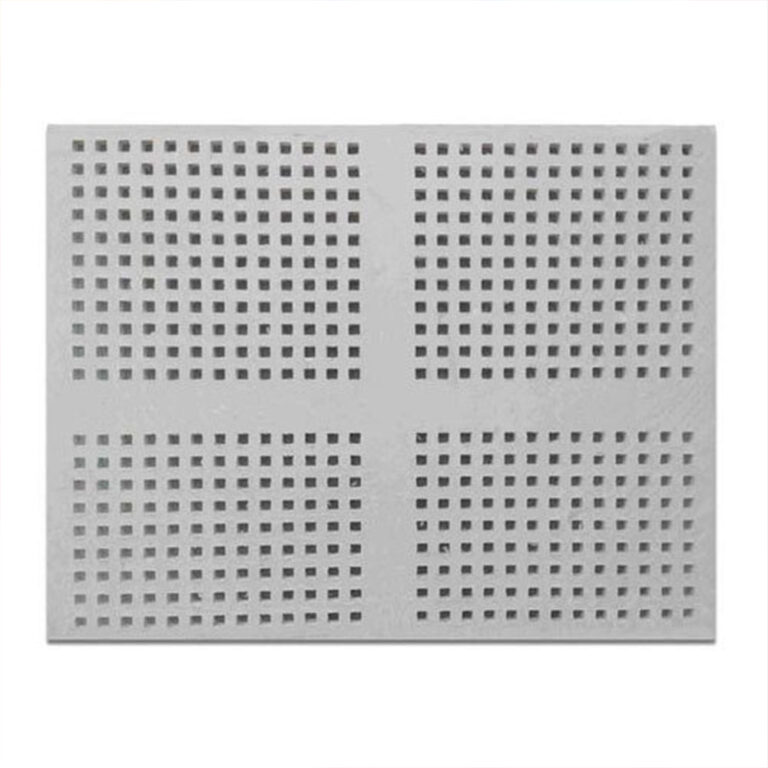

Benutzerdefinierte Loch dekorative perforierte Kunststoff Mesh Sheets Händler

Maßgefertigte perforierte Kunststoffgitter bieten Haltbarkeit, Korrosionsbeständigkeit und ein leichtes Design. Ideal für dekorative Verkleidungen, Belüftungs- und Filtrationsanwendungen. Erhältlich in verschiedenen Lochgrößen und anpassbaren Formen für industrielle und architektonische Anwendungen.

UHMWPE Plane PE Material für Beleuchtung geschnitten & extrudiert

UHMWPE-Planen aus PE-Material bieten eine hervorragende Haltbarkeit und Wetterbeständigkeit. Es lässt sich leicht zuschneiden und extrudieren und ist ideal für Beleuchtungs-, Bau- und Industrieanwendungen. Es bietet UV-, Feuchtigkeits- und Chemikalienschutz mit lang anhaltender Leistung im Innen- und Außenbereich.

Auslegerpolster Ultrahochmolekulares Polyethylen HDPE

Unsere UHMWPE- und HDPE-Auslegerpolster bieten hervorragende Festigkeit und Stabilität für schwere Geräte. Diese langlebigen Polster verteilen Lasten effektiv, verhindern Oberflächenschäden und erhöhen die Sicherheit bei Hebevorgängen. Mit einem praktischen Griff ausgestattet, sind sie ideal für Kräne und...