-

Tian Dong Industrial Park, Decheng District Economic and Technological Development Zone, Dezhou City

Chemical Resistance Quick-Ref: Uhmwpe/Hdpe Vs Common Industrial Media

If you choose the wrong plastic for a tank, liner, or ground mat, you don’t just replace one sheet.

You lose production, you clean a big mess, and sometimes you even scrap a full batch.

That’s why we talk so much about chemical resistance when we design UHMWPE & HDPE sheets and plates at Dongxing Rubber.

Let’s walk through the real picture, in simple words, with a quick table you can keep in mind.

Table of Contents

Why Chemical Resistance For UHMWPE/HDPE Sheets Matters

UHMWPE and HDPE look similar on paper:

- both are polyethylene

- both are light, tough, and easy to machine

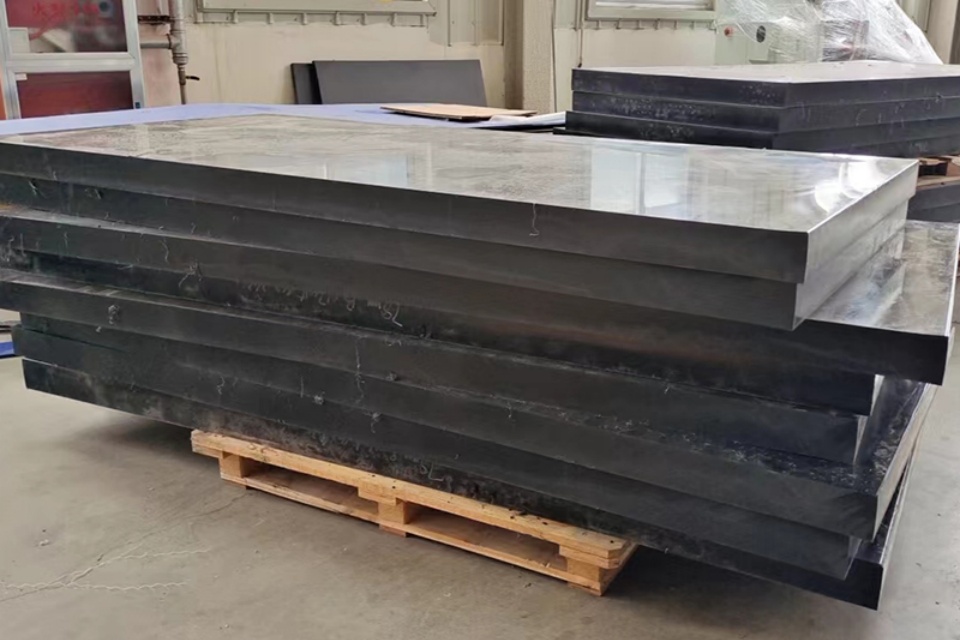

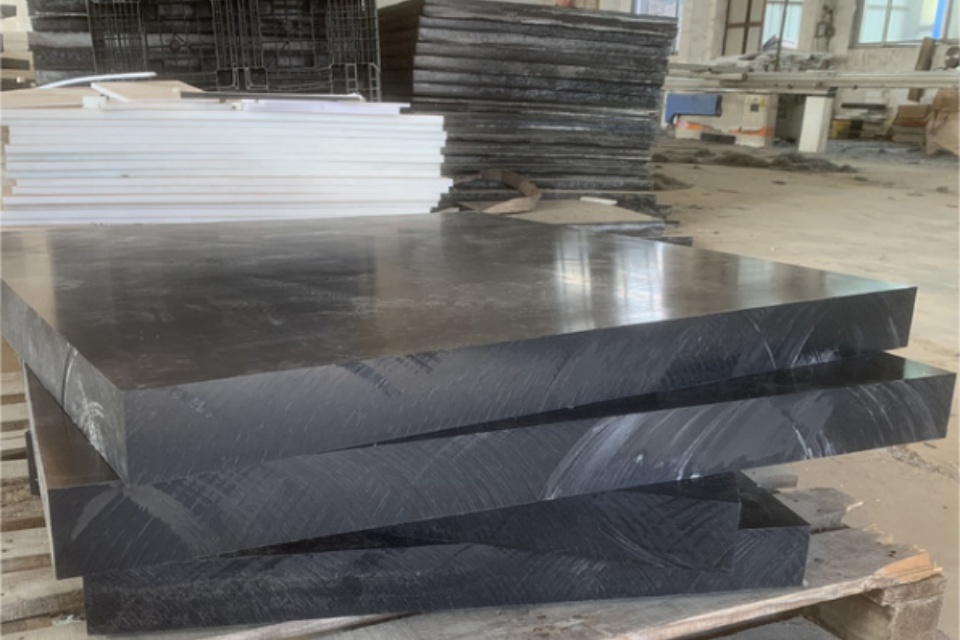

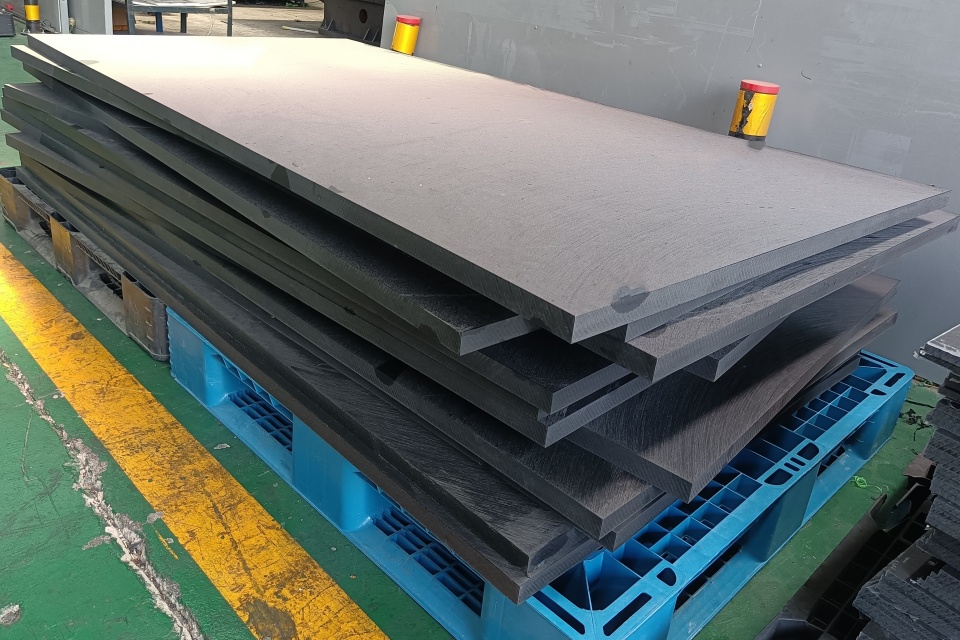

- both are common for tanks, chute liners, road mats, ice rink boards, and fender pads

But in the field you care about other things:

- will this sheet soften or swell in my chemical?

- what happens when the temperature jumps?

- does it still behave the same after five years of wash-down and CIP?

- can I put the same material into food area and acid area?

If the answer is wrong, your nice UHMWPE HDPE sheets & plates become just one more maintenance headache.

Chemical Resistance Of UHMWPE/HDPE To Non-Oxidizing Acids, Bases, And Salts

Good news first. For most “normal” process media, both materials perform very well.

Typical “green zone” media:

- hydrochloric acid at low and medium concentration

- diluted sulfuric acid

- many organic acids like acetic (at normal levels)

- sodium hydroxide / caustic soda cleaning solutions

- salt brines, fertilizer solutions, many neutral salt baths

In these cases:

- UHMWPE: very little attack, surface stays stable

- HDPE: also very little change, even after long contact at room temperature

This is why so many plants use PP/PE products and MG engineering plastic sheets for:

- pickling tanks

- fertilizer hoppers

- salt water storage

- flue gas washing skids

- chemical transfer trays

If your media list is mostly non-oxidizing acids, alkalis, and salts at moderate temperature, UHMWPE and HDPE are both safe starting points.

Limits In Strong Oxidizing Acids And Oxidizing Agents

Now the red zone.

Both UHMWPE and HDPE don’t like:

- high-concentration nitric acid

- very strong sulfuric (70–98 %) at high temperature

- fuming acids

- strong oxidizing mixes (like acid + oxidizer)

- aggressive peroxide blends at high temperature

- free halogens (chlorine, bromine) in strong form

Here the polymer chain can crack, the surface can get brittle, and you can see crazing, stress cracking, or full attack.

In this area, the normal playbook in plant design:

- don’t push UHMWPE and HDPE too hard

- think about fluoropolymers or other high-end materials

- or keep exposure short and cold, if you really must

So for a nitric acid pickling line, for example, PE sheets are usually not your main wall material, they may only appear in small parts with controlled contact.

UHMWPE/HDPE Chemical Resistance In Organic Solvents

Organic solvents are a bit more tricky. The name of the solvent is not enough; you also need the family.

In general:

- Alcohols (ethanol, isopropanol, many glycols)

- UHMWPE: behaves well at room temperature

- HDPE: also stable, surface change is very small

- Aliphatic hydrocarbons (hexane, mineral oil, diesel-type stuff)

- UHMWPE: usually “OK but watch swelling”

- HDPE: similar behavior, small swelling under some conditions

- Aromatics (toluene, xylene) and chlorinated solvents

- both UHMWPE and HDPE can swell a lot

- mechanical properties drop, especially under load

- at high temperature this get really bad

So if you run a pump skid with hexane and a bit of alcohol, PE can be fine.

But for hot toluene recirculation at high temperature, this is not a good idea. You don’t want your support pads to creep and sag under the pump frame.

Effect Of Temperature And Concentration On Chemical Resistance

Here is where many design mistakes happen. The name of the chemical is the same, but the conditions are not.

Key rules of thumb:

- higher temperature = faster attack, more swelling

- higher concentration = stronger attack

- longer exposure time = more damage

- mechanical stress + chemical = stress cracking risk

So a HDPE tank that looks perfect for 30 % acid at 25 °C can start to suffer if you move to 60 % at 60 °C.

Same chemical name, but a different world.

When you talk with Dongxing Rubber about a project, don’t just send “sulfuric acid”.

Send:

- concentration range

- working temperature and cleaning temperature

- contact time (continuous, batch, splash)

- mechanical load (static, dynamic, impact)

This is real process engineer talk, not just catalog talk.

UHMWPE vs HDPE Chemical Resistance And Mechanical Safety Margin

From a chemistry point of view, UHMWPE and HDPE are very close.

In many charts, their chemical resistance rating looks almost same.

So why do designers still pay more attention to UHMWPE for hard jobs?

Because UHMWPE has:

- much higher molecular weight

- better impact strength

- better wear resistance

- excellent sliding behavior

So the chemical window is similar, but the mechanical safety margin is bigger.

Typical logic in real projects:

- HDPE for tanks and big plates in soft service

- UHMWPE for liners, impact zones, chute bottoms, chain guides, and ground protection & road mats

When you combine chemical attack + abrasion + impact, UHMWPE is the “more safe” choice in many scenarios, even if the pure chemical rating is same.

Chemical Resistance In Food, Beverage, And Pharma Cleaning Media

In food and cold-chain projects, you don’t only fight chemicals.

You fight them together with:

- repeated hot water rinse

- frequent caustic cleaning

- disinfectants like hypochlorite

- mechanical impact from trays, trolleys, pallets

Here UHMWPE is popular in:

- ice rink products and boards

- conveyor side guides

- cutting boards and wear strips

- cold room bumpers and impact pads

Why? Because:

- it resists typical CIP alkalis and mild acids

- it handles salt spray and brine

- it doesn’t suck up water

- it keeps low friction for a long time

For radiation areas or nuclear medicine rooms, lead-boron polyethylene plates add another layer:

- base PE matrix with good chemical behavior

- plus shielding fillers for neutrons and gamma

So you still get similar compatibility with many cleaning chemicals, plus the shielding function.

Example Quick-Ref Table For UHMWPE/HDPE Chemical Resistance

You can use this table inside your design notes.

It’s not a full spec, but it gives a fast feeling.

| Media group | Typical examples | UHMWPE behavior (ambient) | HDPE behavior (ambient) | Design comment |

|---|---|---|---|---|

| Non-oxidizing acids | HCl, diluted H₂SO₄, acetic | Very good, little or no visible attack | Very good, little or no visible change | Often first choice for sheets & plates and liners. |

| Caustics and alkalis | NaOH, KOH cleaning liquids | Excellent, stable even at high conc. if not too hot | Excellent, also very stable | Ideal for CIP tanks, wash lines, cabinet interiors. |

| Salt solutions / brines | NaCl, nitrates, sulphates | Excellent, almost no effect | Excellent, almost no effect | Good for fertilizer, brine tanks, cold-room hardware. |

| Alcohols & glycols | Ethanol, IPA, glycols | Very good, low swelling | Very good, low swelling | OK for dosing systems and wash fluids. |

| Aliphatic hydrocarbons | Hexane, mineral oils | Good, some swelling at higher temp & long time | Good, similar pattern | Watch for combined load + temperature, design some margin. |

| Aromatics/halogenated | Toluene, xylene, chlorinated solvents | Swelling, property drop in long or hot service | Swelling, often not recommended in hot service | Better to go for other plastics here, not UHMWPE/HDPE. |

| Strong oxidizing acids | Concentrated HNO₃, hot strong H₂SO₄ | Poor, strong attack and cracking possible | Poor to limited, especially at high temp | Use more resistant materials, PE only for very soft conditions. |

Of course, always check final data with the detailed chart, but this at least keep your mind in the right zone.

How To Use Chemical Resistance Charts Before You Call Dongxing Rubber

To wrap up, here is a short “engineer checklist” you can use before you send your RFQ:

- List every medium, including cleaning liquids and emergency chemicals.

- For each one, write concentration, temperature, and contact time.

- Mark which parts see impact, sliding, or heavy wear.

- For wear zones, think UHMWPE sheets and liners first.

- For big, static panels with gentle media, HDPE plates often enough.

- For shielding plus chemical resistance, look at lead-boron polyethylene plates.

When you share this info with Dongxing Rubber, we can match you with:

- the right UHMWPE HDPE sheets & plates

- custom cut size and machining

- OEM/ODM support for PP/PE products, nylon sheets, ground mats, ice rink boards, and more

- bulk wholesale options for your long-term projects

This way you don’t just “guess a plastic”.

You build a line that runs stable, less leak, less fire-fighting maintenance, and your customer feel you really know the process, not only the catalog.