-

Tian Dong Industrial Park, Decheng District Economic and Technological Development Zone, Dezhou City

About Us – Top 1 UHMWPE Manufacturer

We’re a large-scale manufacturer focused on UHMWPE, HDPE, and engineering plastics—combining material science, machining, and application know-how to deliver durable, low-friction solutions.

Company Overview

Dezhou Dongxing Rubber & Plastic Co., Ltd. is one of China’s leading large-scale manufacturers of high-performance engineering plastics—specializing in UHMWPE and HDPE—with integrated R&D, precision machining, in-house testing, and full-process production to deliver durable, low-friction solutions for demanding applications. Operating from a modern ~20,000 m² facility equipped with CNC machining centers plus extrusion and casting lines, we support customers from early design through engineering validation, prototyping, batch manufacturing, inspection, and packaging. Our ISO 9001–driven quality system covers raw-material control to finished-product testing (friction, hardness, impact, and wear), while ISO 14001, CE, and FDA food-grade compliance reflect our commitment to safety and environmental stewardship. Serving power generation, ports, mining, papermaking, textiles, chemicals, environmental protection, and sports facilities across 40+ countries, we provide responsive lead times, documented inspection reports, and reliable after-sales service—guided by the principle “Integrity as the Foundation, Quality as the Priority.”

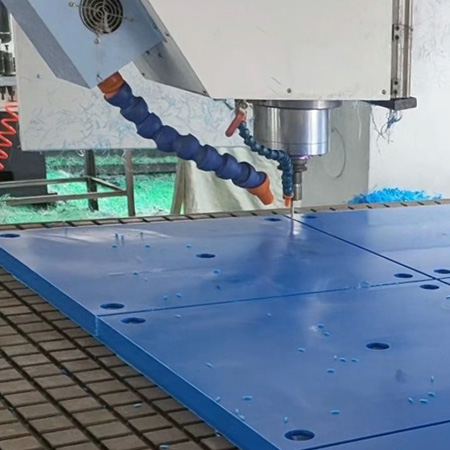

Manufacturing Capability

We operate a modern factory of about 20,000 m², equipped with CNC machining centers plus extrusion and casting lines for sheets and finished parts. A technical team with 25+ years of industry experience delivers customized solutions, supported by an in-house R&D laboratory for continuous material improvement.

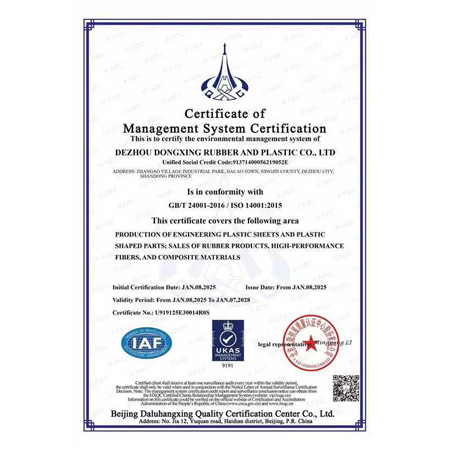

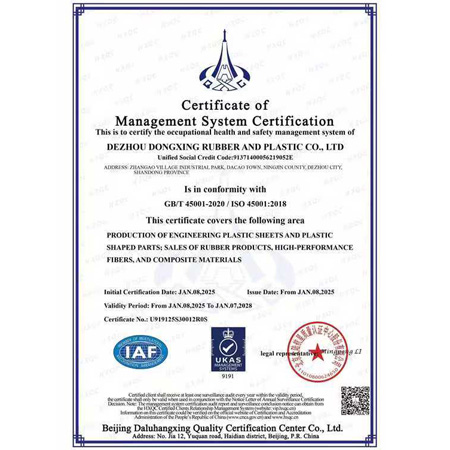

Quality Management & Certifications

We enforce ISO 9001 quality management with a full inspection process: raw materials → production control → finished product testing. On-site equipment measures friction coefficient, hardness, impact strength, and wear resistance. Every batch ships with inspection reports and traceability. Our certifications include ISO9001, ISO14001, CE, and FDA Food Grade, and we hold multiple patents in wear-resistant, low-friction plastics.

Markets & Applications

Our materials replace or complement traditional options across power generation, ports & terminals, coking, coal handling, papermaking, textiles, chemicals, and environmental protection, creating significant economic benefits. We also serve sports arenas and nuclear shielding applications.

We export to 40+ countries spanning Southeast Asia, the Middle East, Europe, South and North America, earning long-term trust through reliable quality and competitive pricing.

Customization Workflow & Business Terms

We specialize in bespoke parts. Provide drawings or samples; we return shop drawings for approval and a firm quote. Typical timelines: samples 3–15 days; batch production 3–20 days (project-dependent). Domestic shipping: 3–5 days; international timing confirmed per order. Payment: full payment to start, or 50% deposit with balance before shipment. After-sales: urgent matters answered within 24 hours and resolved promptly.

Case Studies & Recognition

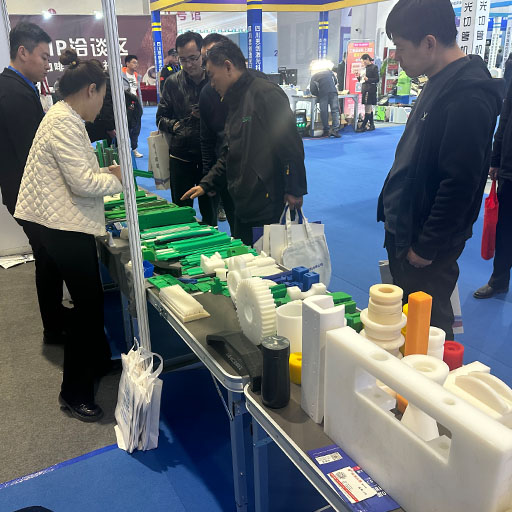

Active exhibitor at Hannover Messe, Canton Fair, CONEXPO (USA), BIG5 (Dubai); recognized as Outstanding Supplier and Trusted Enterprise in consecutive years.

Projects across logistics, mining, power, and packaging show clear gains: UHMWPE liners and wear parts cut friction, protect surfaces, and extend service intervals, turning downtime into throughput and lowering total cost of ownership at lower cost.

Chosen by OEMs and end users worldwide, we deliver consistent quality, rapid response, and on-time supply. From quotation to commissioning, our engineering support streamlines installation, reduces risk, and sustains reliable performance in the field.