-

Tian Dong Industrial Park, Decheng District Economic and Technological Development Zone, Dezhou City

Logistics Math: Stack Height, Truck Counts, And Crew Time

If you ship hockey rink dasher boards, you already know the funny part: the boards aren’t “hard” to make. The hard part is getting them to the rink on time, in good shape, and without a dock-day meltdown.

This is why I like “logistics math.” Not big spreadsheets. Just clean, fast numbers you can do before lunch. Stack height. Truck counts. Crew time. Those three decide if your delivery feels smooth… or feels like a small disaster.

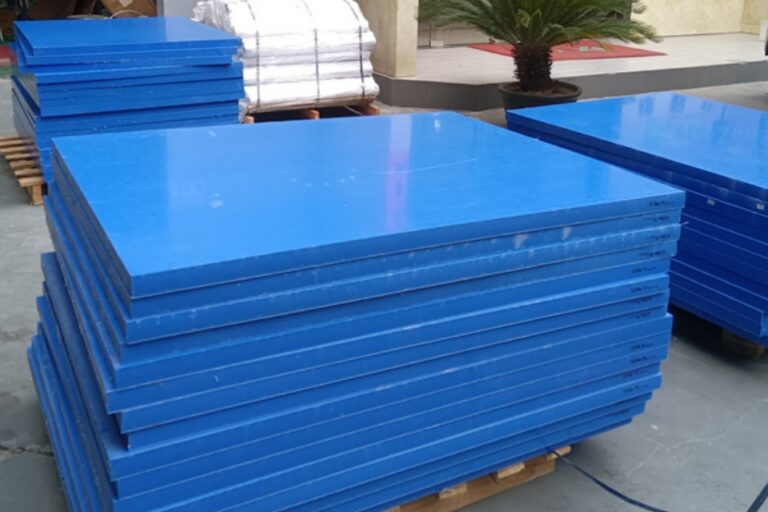

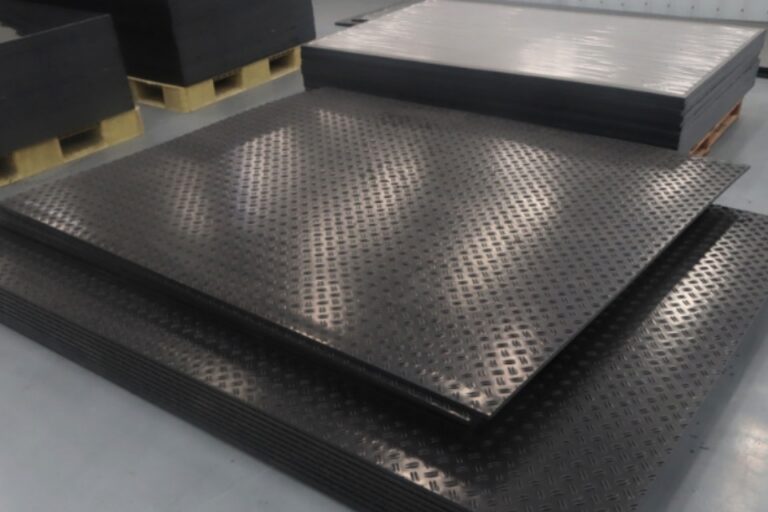

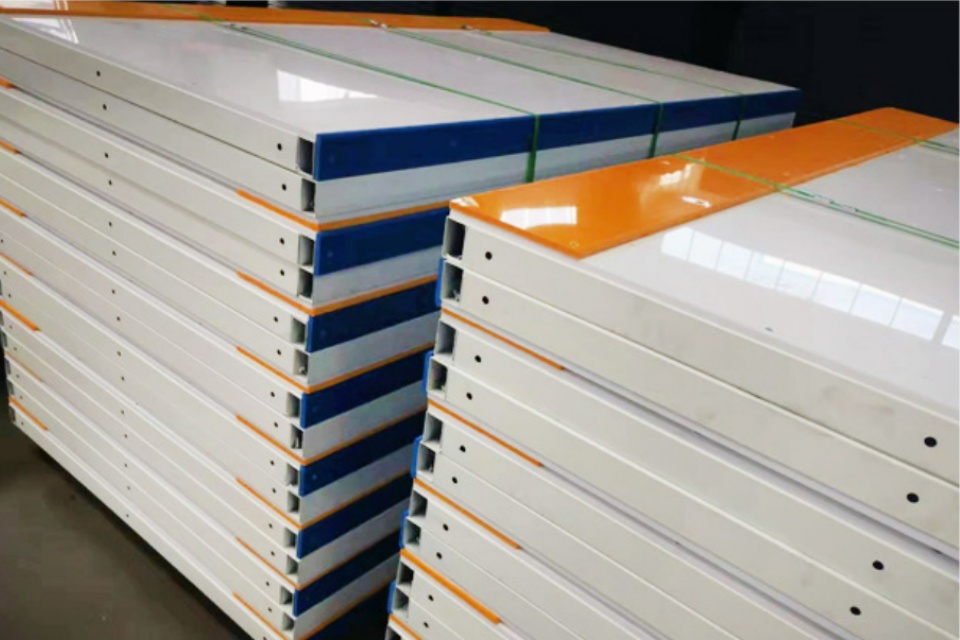

I’ll frame this around custom UHMWPE/HDPE hockey rink dasher boards like the ones here: hockey ice rink dasher boards (custom sizes are available, and the boards focus on impact and wear resistance).

Table of Contents

Hockey (Ice) Rink Dasher Boards

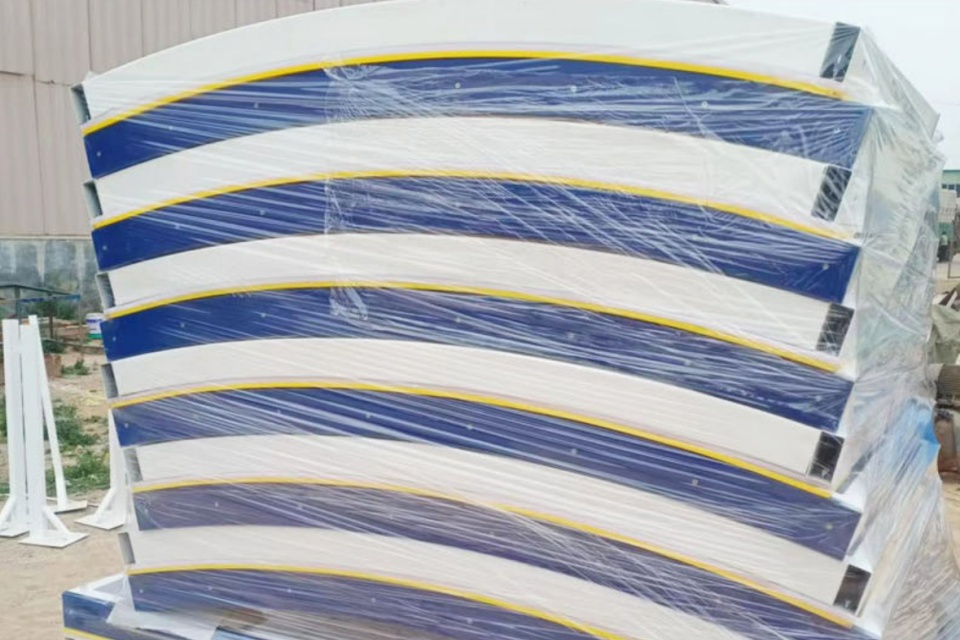

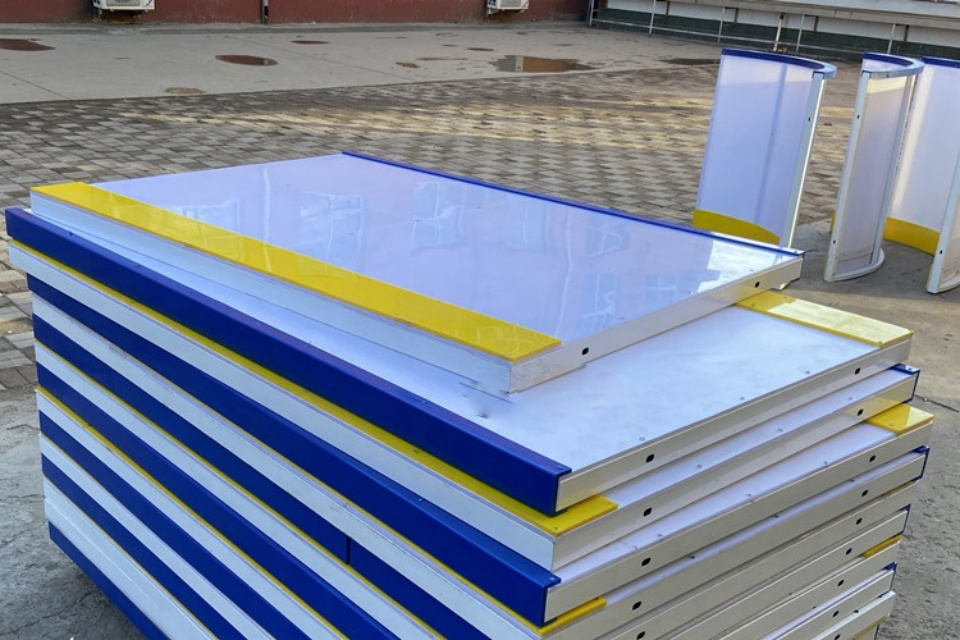

Dasher boards look simple from far away. Up close, they’re a mixed load: panels, corner sections, caps, posts, hardware kits, maybe gates. Some items stack nice. Some items fight you.

On the manufacturing side, your supplier might offer free design, custom service, and fast production & delivery, plus ISO-style quality control.

And yes, this site is tied to Dezhou Dongxing Rubber & Plastic Co., Ltd.

Now let’s talk about what happens after the boards are finished: the truck shows up. The dock clock starts. The crew starts asking questions. That’s where the math helps.

Stack Height

Stack height is not a pride contest. It’s a safety and speed decision.

If you stack too low, you waste cube and add trucks. If you stack too high, you invite warp, cracked corners, crushed packaging, or a sketchy load that “walks” during transit. And then your crew wastes time un-fixing it.

Stack Height Limits

You usually have three real limits:

- Packaging limit: will the bottom layer survive the weight above it?

- Handling limit: can a forklift lift it safely without wobble?

- Trailer limit: will it clear the door and roof bows?

Here’s a practical stack-height decision table you can use in a pre-ship call:

| Stack approach | What it’s good for | What can go wrong | When I’d use it |

|---|---|---|---|

| Single-stack (one layer per skid) | Fast unload, low damage risk | More trucks, more dock slots | Small projects, tight deadlines, new crew |

| Double-stack (two layers) | Better cube, fewer trucks | Higher crush risk, higher tip risk | Stable packaging + forklift crew that knows the drill |

| Mixed-stack (heavy low, light high) | Balanced load, better stability | Easy to mess up in the yard | Mixed kits (panels + hardware + trim) |

| “Too tall” stacks | Looks efficient on paper | Bad wrap integrity, leaning skids | Honestly… don’t do it |

Quick shop-floor slang that matters here: wrap integrity and unit load stability. If the load can’t survive a hard brake, it’s not “done.” It’s just waiting to fail.

Truck Counts

Truck counts sound simple: “How many trucks?”

But the real question is: How many trucks, at what loading pattern, with what dock schedule?

Pallet Count and Trailer Cube

You don’t need perfect numbers. You need repeatable assumptions.

Start with these inputs:

- Units per skid (or crate)

- Skids per truck (based on your typical pattern)

- Any “cannot stack” rules (hardware on top of panels, gates separate, etc.)

Then use the clean formula:

Truck count = ceiling(Total skids ÷ Skids per truck)

Here’s a sample planning table (example only, you’ll plug in your own counts):

| Project bundle | Total skids | Target skids/truck | Planned trucks | Notes |

|---|---|---|---|---|

| Main dasher board panels | 18 | 9 | 2 | Keep panel skids together for easy staging |

| Corners + caps + trim | 6 | 6 | 1 | Light but awkward shapes |

| Gates + hardware kits | 4 | 4 | 1 | Don’t bury hardware, crew will hate you |

| Total | 28 | — | 4 | Build load plan before pickup |

That table looks basic. Good. Basic keeps you alive.

Also, watch the classic shipping trap: you might cube out before you weigh out, or the other way around. Either way, your truck plan changes. So don’t lock your schedule until you confirm your packaging layout.

Crew Time

Crew time is where plans go to die.

A truck arrives “on time,” but unloading drags. Now the driver waits. The dock gets backed up. The rink team gets grumpy. People start doing dumb stuff like cutting wrap too early.

So you plan crew time the same way you plan trucks: with simple rules.

Live Unload vs Scheduled Unload

Two common dock setups:

- Live unload: driver waits while you unload right now.

- Scheduled unload: you slot the truck into an appointment window.

If you can’t guarantee crew + forklift + dock space, live unload gets messy real fast. The detention clock starts ticking (and yeah, nobody likes that talk).

Crew Time Math

Use this sticky-note formula:

Total unload minutes = (Skids × Minutes per skid) ÷ Number of unload lanes

Then adjust for reality: tight dock, long push, liftgate, snow, new operator… you know.

Here’s a crew-time table you can reuse:

| Unload scenario | Minutes per skid (rule of thumb) | Crew + equipment | Risk level |

|---|---|---|---|

| Forklift unload, staged dock | 4–7 | 1 forklift + 2 people | Low |

| Forklift unload, tight dock | 7–12 | 1 forklift + 3 people | Medium |

| Pallet jack only (no forklift) | 10–18 | 4 people | High |

| Hand-unload / floor-loaded | 18–35 | 5–8 people | Very high, and everyone will be tired |

No, those numbers won’t be perfect. They don’t need to be perfect. They need to be honest enough that you don’t book a 30-minute window for a 3-hour job. That’s where you get burned.

And yeah, sometimes the crew is late, or the forklift battery is dead. It happens. Plan for it, dont pretend it won’t.

Dock Scheduling

Dock scheduling is where stack height and crew time meet.

If you double-stack to reduce trucks, you may increase unload time because the crew needs more careful handling. That can wipe out the “saved” time you thought you won.

Here’s a fast checklist (print it, tape it to a wall, whatever):

- Confirm dock type: leveler, ramp, yard access

- Confirm equipment: forklift capacity, forks length, spare battery

- Confirm unload flow: where skids will land, how they get staged

- Confirm packaging rules: “Do not stack,” “Keep hardware visible,” “Gate skids separate”

- Confirm who signs and who counts (counting on-site is always slower than you expect)

This is also where working with an OEM/ODM manufacturer helps. If your supplier does custom service and moves fast, you can tune packaging for the customer’s dock reality, not just for your warehouse convenience.

OEM/ODM Services

For B2B rink builders and wholesalers, OEM/ODM isn’t just branding. It’s logistics control.

When the supplier can adjust panel sizing, bundle logic, labeling, and packing sequence, you can:

- reduce mis-picks at install

- speed up staging

- cut “where is the hardware” chaos

- keep the crew moving

This site calls out high quality and fast delivery, backed by testing and efficient production.

That matters, because logistics math only works if the load is consistent. Random packaging kills every plan.

Also, if you want the clean “one team, one spec, one packing rule” setup, link your project to the OEM/ODM workflow early. It saves a lot of back-and-forth later.

Closing Thought

Here’s the truth: you can’t control every dock, driver, or weather day. But you can control your math.

- Stack height controls damage risk and unload stability.

- Truck counts control schedule pressure.

- Crew time controls whether the delivery feels smooth or painful.

Do the simple math early. Share it with your customer. And if you’re pairing boards with rubber parts or rink-side protection, it’s normal to coordinate those details with suppliers like Dongxing Rubber so the whole system lands right the first time.

That’s not fancy. It’s just how real projects stay on track.