-

Tian Dong Industrial Park, Decheng District Economic and Technological Development Zone, Dezhou City

Connecting Systems: Pins, Plates, And Interlocks Compared

When you lay ground protection mats for a temporary roadway, the mat isn’t the only thing doing the work. The connection system does a quiet, brutal job too. It fights drift, edge lift, and that ugly “mat walk” you see after a loader turns hard.

If you buy or wholesale Ground Protection & Road Mats (especially Dura Mats), you already know this pain: the jobsite looks fine at 8:00, then one hour later the lane starts opening up like a zipper. Now you’re pulling mats back, again. People get mad. Schedules slip. It’s not fun.

Dongxing Rubber builds for B2B buyers who need OEM/ODM, bulk orders, and repeatable quality across projects.

(And yep, you can start here: Ground Protection & Road Mats and Dura Mats.)

Below, I’ll compare pins, plates, and interlocks in a way that matches real site conditions, not lab dreams.

Table of Contents

Heavy equipment temporary roadway stability: drift, edge lift, separation

Let’s say you’re building an access lane for a crane delivery. The soil is soft. The trucks arrive early. The operator turns the steering wheel like they’re driving a kart.

That’s when connectors matter.

- Drift happens when mats “creep” sideways with repeated rolling load.

- Edge lift shows up when a corner pops up and catches a tire or track.

- Separation is the classic gap you see after turning traffic.

You don’t just want mats to touch. You want the lane to behave like one surface, or close to it. That’s why many Dura/Base style mats focus on creating durable temporary roadways and work surfaces with textured, non-slip patterns for stability.

Pin connection system: fast locking in muddy sites and high-cycle installs

Pins win when your crew needs speed and simple moves.

Where pins shine

- Muddy, messy sites: you can usually clear a hole and drop a pin faster than you can line up hardware and start threading bolts.

- High-cycle projects: if you lay, pull, and re-lay mats all week, pins keep your workflow moving.

- Heavy turning zones: pins help reduce that “mat shift” at intersections and tight radiuses.

Real scene: wind farm build-out. The lane stays open for months. Crews constantly “patch” sections as cable pulls and deliveries change. Pins feel like the least annoying option. You can keep a small kit and just go.

One more thing: pins make sense when you need fast “lane edits.” Move the edge 1 mat width, add a passing bay, then lock it back up. No drama, if the hole pattern matches.

Pin compatibility and alignment: hole pattern, tolerance, and missing hardware

Pins also come with hard limits. They’re not magic.

The pain points

- Alignment: if the ground is uneven, holes don’t line up clean. You end up prying and kicking mats into place. It gets old fast.

- Tolerance stack: a tiny twist across a long lane becomes a big misalignment at the far end. That’s how you get crews saying “these mats dont fit,” even when they do.

- Hardware control: pins are small. Pins get lost. Then the lane turns into a half-connected mess.

If you plan to mix mat types (or mix suppliers), pins can turn into a compatibility trap. So, for B2B buyers, standardizing hole spacing across SKUs is a huge win. This is where OEM/ODM work pays off, because you can lock a connector spec early and keep it consistent across your orders.

Plate connectors and bolted couplers: simple, steady, slower install

Plates (or couplers) are the “old reliable” option. They usually mean a connector plate + bolts/nuts that clamp mats together.

Where plates work well

- Long straight runs: fewer tight turns, less shear force, less connector drama.

- Permanent-ish temporary roads: if the lane stays down for weeks, slower install matters less.

- Crews with tools and time: plates are great when the install team runs a clean process.

But here’s the catch: plates ask for discipline. You need:

- the right tools on hand,

- torque consistency (at least “tight enough”),

- a way to store hardware so it doesn’t vanish into the mud.

If your site is chaos, plates can feel… kinda painful. People rush. Bolts go missing. Then the lane loosens little by little. It’s not the plate’s fault. It’s the jobsite.

Interlocking edges: fast laydown, better continuity, not always enough for heavy rolling loads

Interlocks feel amazing when you want fast coverage. You drop a mat, slide it in, and keep moving. On lighter duty lanes, interlocks can be all you need.

A lot of Dura/Base style products talk about interlock designs and non-slip diamond patterns to keep the surface stable for machinery on tough ground.

Where interlocks work best

- Event build-outs (forklifts, carts, light vehicles)

- Pedestrian routes on turf

- Short access pads where turning traffic is limited

Where interlocks struggle

- Heavy turning loads (loaders, telehandlers, tracked machines)

- Stop/start traffic (delivery trucks braking and accelerating on the lane)

- Steep approaches where gravity and tire scrub fight the joint

In those cases, interlocks can still be useful, but crews often add a second layer of “locking” thinking: pin + interlock, or plate + interlock. You don’t always need both, but you should at least consider it.

Comparison table: pins vs plates vs interlocks for ground protection mats

Below is a field rule-of-thumb table. It’s not a lab test. It’s the stuff people say after doing this too many times.

| Factor | Pins | Plates / Bolted Couplers | Interlocking Edges |

|---|---|---|---|

| Install speed | Fast | Medium to slow | Very fast |

| Best on muddy sites | Good | Mixed (threads hate mud) | Good (until joints pack with debris) |

| Turning traffic resistance | Good | Good (if tightened well) | Medium |

| Hardware loss risk | Medium (pins disappear) | High (small parts everywhere) | Low (no separate parts) |

| Lane reconfiguration | Easy | Slower | Easy |

| Typical failure mode | Missing pins, misalignment | Loose bolts, lost hardware | Edge lift, joint separation under shear |

| Best fit use-case | High-cycle construction lanes | Long-term temporary roads | Fast coverage, lighter duty lanes |

Decision matrix: pick the connector based on site behavior

| Site condition (what you really see) | What it usually means | Connector lean |

|---|---|---|

| Mats “walk” sideways after every shift | High shear from turning and braking | Pins or plates |

| Corners pop up near intersections | Edge lift + joint stress | Pins (often) + better layout |

| Crew keeps changing the lane shape | High rework + schedule pressure | Pins or interlocks |

| Hardware keeps going missing | Weak kitting + messy storage | Interlocks (or captive hardware design) |

| Lane stays down for weeks | Low change frequency | Plates or pins |

Where Dongxing Rubber fits for Dura Mats buyers

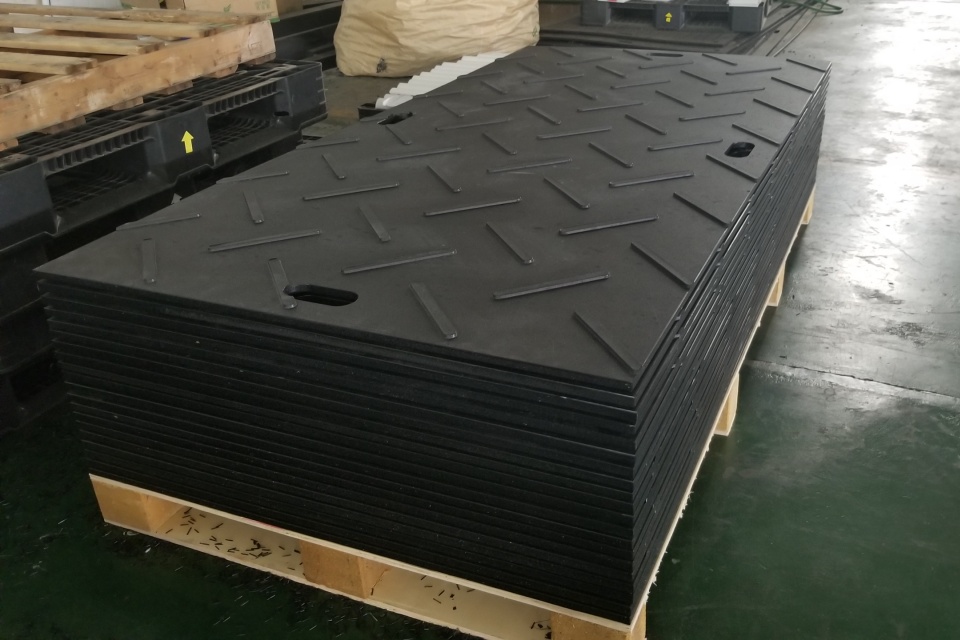

If you’re sourcing Dura Mats for wholesale or project supply, you’re not only buying a mat. You’re buying a system: surface pattern, stiffness, handling, and the connector strategy.

Dongxing Rubber positions itself as a large-scale manufacturer for high-performance engineering plastic products, with B2B support like custom design and mass production.

That matters because connector decisions often turn into OEM details:

- hole pattern standardization,

- plate thickness and shape,

- interlock geometry,

- “same mat, different market” labeling and packing.

Do that work once, and your installs get smoother across many jobs. Do it sloppy, and every site becomes a mini experiment (and nobody wants that).

A quick, practical takeaway

- Choose pins when speed and repeat installs are king.

- Choose plates when stability matters and the crew can keep hardware under control.

- Choose interlocks when you need fast coverage and the load profile is lighter—or when you can pair interlocks with another locking method.

And yeah, sometimes the best answer is boring: pick one system, standardize it, train the crew, and stick to it. That alone fixes alot.