-

Tian Dong Industrial Park, Decheng District Economic and Technological Development Zone, Dezhou City

Ground Protection Mats 101: When To Choose HDPE vs UHMWPE

If you’ve ever watched a forklift sink into soft ground, you already get the problem. The job might be simple, but the ground is not. One rainy day and your “easy access road” turns into a mud soup.

That’s why ground protection mats exist. They spread load, protect turf, and keep machines moving. Now the real question: HDPE or UHMWPE? Pick wrong and you’ll see ruts, spinning tracks, cracked edges, or a mat surface that turns slick over time.

Let’s break it down in a real, jobsite way.

Table of Contents

Ground protection mats and ground bearing pressure

A mat is basically a “pressure spreader.” You take a high point load (a tire, an outrigger, a track edge) and spread it over a bigger area. That drops ground bearing pressure and helps stop rutting, sink-out, and pump-out (that nasty squish where wet soil pushes up).

Point loading vs distributed loading

- Point loading: small contact area, high pressure (outriggers, jack legs, stabilizers).

- Distributed loading: larger area, lower pressure (wide tires, long tracks).

If your job looks more like point loading, you usually care more about stiffness, thickness, and structure. If your job looks more like distributed loading plus lots of turning and sliding, surface wear starts to matter a ton.

HDPE ground protection mats

HDPE is the workhorse choice on many sites. It’s tough, it’s cost-friendly, and it handles weather well.

When HDPE makes the most sense

Pick HDPE mats when you need:

- General access and laydown yards (forklifts, scissor lifts, small cranes).

- Fast deployment and easy handling.

- Big mat quantities for site logistics.

- A mat that can take bumps, water, and sun without getting fussy.

HDPE also tends to be easier for certain fabrication steps, like welding and general machining. So if you need special sizes, hand holes, or edge features, HDPE often keeps things simple.

HDPE pain points you should watch

HDPE can still fail if the job is rough:

- Repeated track turns can chew up the surface.

- Grit + rotation can polish it over time (yep, it can get more slippery).

- If you run heavy gear on thin mats, you can see bending, edge curl, or local deformation. Not always, but it happens.

UHMWPE ground protection mats

UHMWPE is the “wear life” pick. People like it because it fights abrasion and slides well. That matters when your equipment isn’t just rolling straight.

When UHMWPE is the better call

Choose UHMWPE when you deal with:

- Tracked equipment that pivots or skid-steers a lot.

- High abrasion (sand, crushed stone, gritty soil).

- Frequent drag / pull / reposition (mats get moved all day).

- Jobs where you can’t afford downtime because mats start failing mid-project.

It’s not magic, but it usually takes longer to look beat up. And in real life, that’s what you pay for: less drama, longer service life, fewer swaps.

UHMWPE “gotchas”

UHMWPE can be softer in stiffness than you might expect, depending on design. So you still need to match thickness and structure to the load. Don’t assume “UHMW = invincible.” It ain’t.

HDPE vs UHMWPE: typical material properties

Numbers don’t tell the whole story, but they help you explain decisions to a customer or a procurement team.

Below is a typical comparison pulled from common plastics datasheets (ASTM methods). Your exact values vary by grade and supplier, so treat this as a baseline, not a promise.

| Property (typical, ASTM methods) | HDPE | UHMWPE |

|---|---|---|

| Density (D792) | ~0.96 | ~0.93 |

| Tensile strength (D638) | ~4,000 psi | ~3,100 psi |

| Elongation (D638) | ~600% | ~350% |

| Flexural modulus (D790) | ~200,000 psi | ~110,000 psi |

| Hardness Shore D (D2240) | ~69 | ~64 |

| Low friction behavior | good | very good |

| Abrasion resistance | good | excellent |

How to read this: UHMWPE often wins on wear and sliding. HDPE often feels stiffer in many setups. For mats, design matters as much as resin.

Coefficient of friction and “slick mat” risk

Here’s a jobsite truth: a mat that starts with good traction can turn into a slip-and-slide if the surface gets polished. You’ll see it when:

- Tracks pivot in place (rotational shear).

- Fine sand acts like sandpaper.

- Mud dries and creates a smooth film.

Practical rule

- If you expect a lot of pivoting, spinning, dragging, UHMWPE usually holds up better.

- If you expect mostly straight traffic and you want a stable, simple option, HDPE often works great.

Also, don’t ignore texture. A smart tread pattern can save you more than the resin choice.

Abrasion resistance and track turn abuse

Tracked machines don’t “roll.” They grind. That grinding is basically abrasion plus heat plus grit. If your mats live under track turns, you’re in a wear fight.

- HDPE: handles plenty of jobs, but heavy track abuse can eat the surface faster.

- UHMWPE: typically resists abrasive wear better, so it usually stays “usable” longer.

If you’ve ever heard a superintendent say, “These mats got shredded,” that’s often a track-turn story.

Creep, cold flow, and long dwell loads

If your machine sits in one place for hours (or days), plastics can deform slightly over time. People call it creep or cold flow.

What you do about it (no fluff)

- Use the right thickness.

- Increase contact area (bigger mat, better load spread).

- Avoid tiny contact points (small feet, sharp edges, steel corners).

If you’re handling outriggers a lot, you might also look at crane outrigger pads plus mats as a package. Different tools, same goal: control ground pressure and stop sink.

Thickness, traction pattern, and edge design

This part gets ignored, then it bites you later.

Thickness and stiffness

A thicker mat usually spreads load better and feels more stable under tires. But thicker also means heavier and slower to handle. So you balance:

- safety + performance

vs - speed + manpower

Traction surface

A good tread helps reduce slip, especially on wet turf, snow, or muddy access paths. If you’re working events, landscaping, or soft ground, traction is not “nice to have.” It’s basic.

Edges and connections

On real sites, edges fail first. So features like:

- beveled edges,

- reinforced corners,

- connector holes,

- anti-trip transitions

…can matter as much as resin choice.

Quick selection table: when to choose HDPE vs UHMWPE

| Job condition / pain point | Choose HDPE when… | Choose UHMWPE when… |

|---|---|---|

| General access roads | you need reliable, simple performance | you expect heavy turning and wear |

| Tracked equipment | only occasional track traffic | lots of pivoting / skid-steer action |

| Abrasive ground (sand, gravel) | light-to-medium abrasion | high abrasion, daily abuse |

| Fast deployment | crew needs quick handling | longer life matters more than speed |

| Surface staying “clean” | low rotation and less grit | high rotation, grit, drag, harsh use |

OEM/ODM ground protection mats for your exact site

Most mat “fails” aren’t material fails. They’re match fails. The mat doesn’t match the load, the soil, or the traffic style.

At Dongxing Rubber, we don’t just ship standard pieces and hope for the best. We support:

- custom sizes and thickness options,

- OEM/ODM programs,

- bulk wholesale supply for contractors and distributors,

- fast response when you need spec help (because jobsites don’t wait).

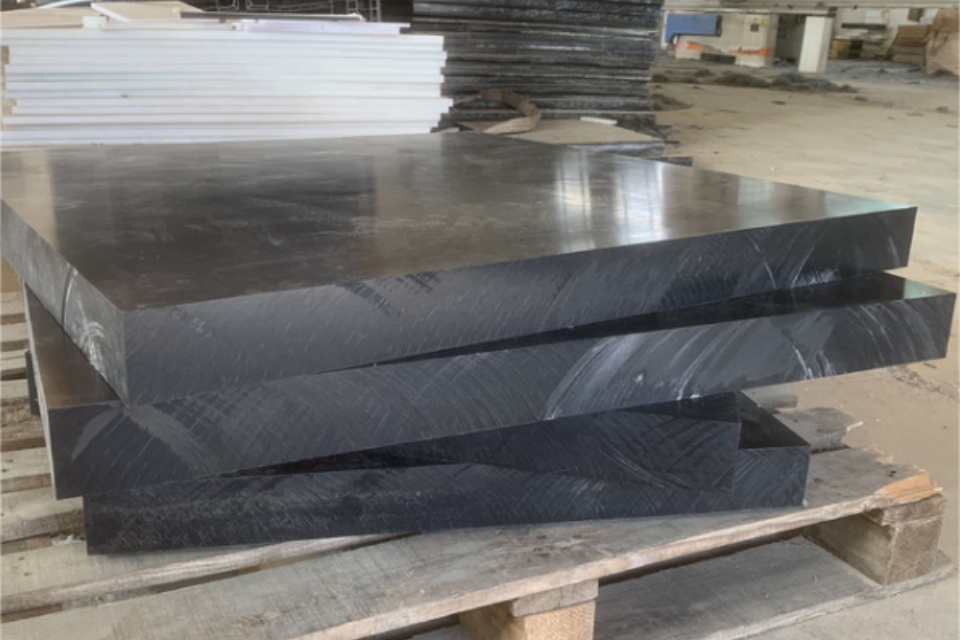

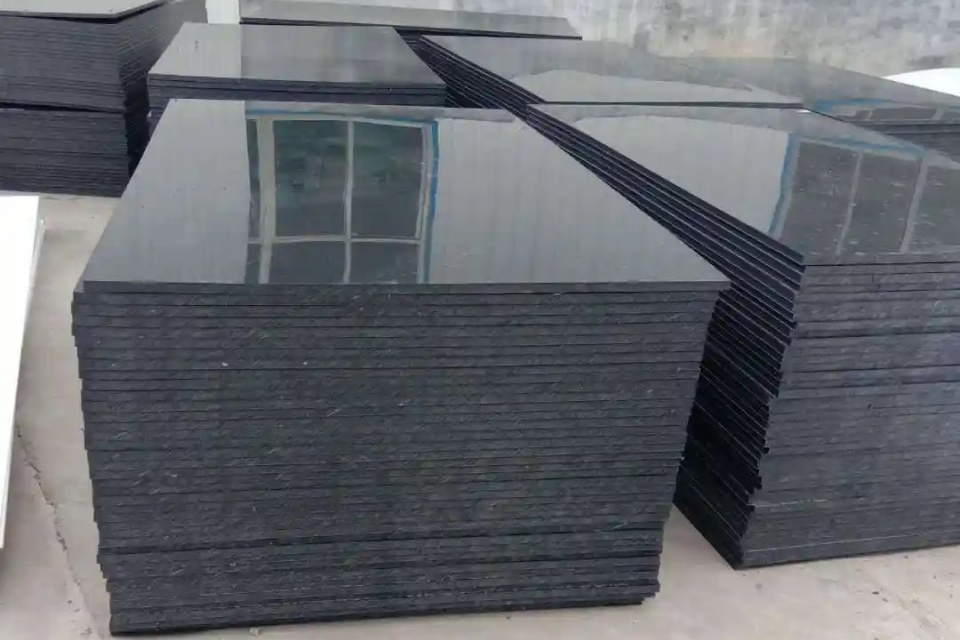

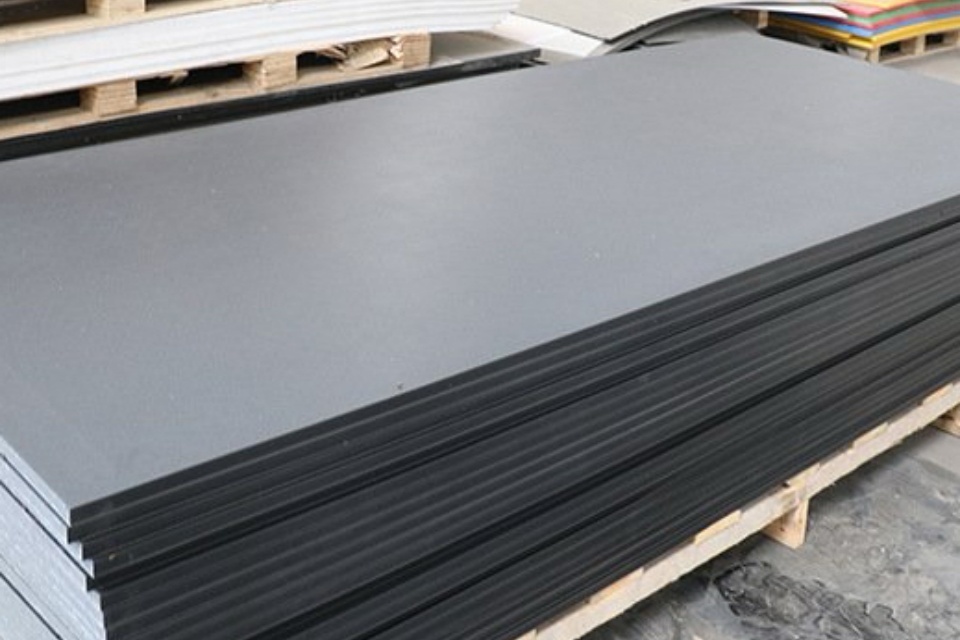

We also manufacture UHMWPE & HDPE sheets and plates, so we can build a mat solution around the real mechanical need, not just a catalog box.

And yes, some customers buy more than mats from us. If your operation also needs shielding material, we supply Lead-Boron Polyethylene Plates too—different use case, same mindset: performance materials, made to fit your job.

Internal references you can check on our site:

- Coal bunker liner use and wear control ideas (good for “material handling abrasion” thinking):

https://uhmwpe-manufacturer.com/coal-bunker-limit-plates/ - Radiation shielding plate overview:

https://uhmwpe-manufacturer.com/lead-boron-polyethylene-plates/

The simple takeaway

If you want a practical default, start here:

- Pick HDPE for general access, fast rollout, and big site coverage.

- Pick UHMWPE when wear is the real enemy—tracked pivots, grit, drag, repeat abuse.

And if you’re stuck between the two, don’t guess. Describe your traffic (wheels vs tracks), soil condition (dry, wet, sandy), and how often you reposition mats.