-

Tian Dong Industrial Park, Decheng District Economic and Technological Development Zone, Dezhou City

Reducing Bridging And Ratholing With Low-Friction Liners

If you run a bin, hopper, or chute long enough, you’ll meet two old enemies: bridging (arching) and ratholing. They show up on the worst days. A truck is waiting. Your line is starving. Someone grabs a mallet. It gets loud, fast.

Here’s my take: most “flow problems” aren’t mystery problems. They’re friction problems, geometry problems, or “this powder hates humidity” problems. Low-friction liners don’t fix everything. But used the right way, they can turn a sticky, temperamental system into something that runs calmer and needs less babysitting.

And yeah—this matters for business. Less hang-up means less downtime, fewer clean-outs, and fewer “we gotta shut it down right now” moments.

Table of Contents

Bridging (Arching) In Hoppers

Bridging happens when material forms a stable arch over the outlet. The bin looks full. The feeder looks hungry. Nothing moves.

Typical bridging causes in bulk solids handling

You’ll usually see one (or more) of these:

- High wall friction: material grips the wall instead of sliding.

- Too-small outlet: the “throat” is basically asking for a blockage.

- Cohesion and moisture: fine powders, damp product, fat/oil, sticky fines.

- Particle interlock: irregular shapes that “lock arms.”

A quick field check you can do today

If you bang the wall and the flow starts for 10 seconds, then stops again, you probably don’t have a feeder issue. You have a wall slip issue or a throat sizing issue. I see this all the time in coal handling, mineral bins, and dusty recycled material.

Ratholing In Silos

Ratholing is when material flows down a narrow channel in the center, while the outside stays stuck. It looks like a “pipe” formed inside your bin.

Funnel flow vs mass flow keywords you should use

- Funnel flow: center moves first, sides stay parked.

- Mass flow: everything moves, top to bottom, wall to wall.

Ratholing loves funnel flow. It leaves dead zones. That means old product sits there. It can cake, rot, harden, or contaminate the next batch. It also steals capacity, so you “feel” short on storage.

Why wall friction shows up again (yep, again)

If the wall grabs the material, the material won’t slide. That’s it. The center drains, the sides cling, and you get a rat-hole.

Wall Friction And Hopper Angle

This is the part most teams skip because it sounds “too engineering.” But it’s the difference between guessing and fixing.

If your hopper wall isn’t steep enough or slick enough, the wall won’t release material. Low-friction liners help because they reduce wall friction and encourage slip.

Typical dry sliding friction (rule-of-thumb ranges)

These are typical ranges you can use to explain the idea. Real values change with load, surface finish, dust, and moisture.

| Surface (liner or wall) | Typical friction trend | What you’ll notice on site |

|---|---|---|

| Polished steel | Medium | Can still hang up with fines and moisture |

| Painted carbon steel | High | Builds up fast, grabs dust like glue |

| HDPE sheet | Medium-low | Better slip, still can smear with warm sticky stuff |

| UHMWPE sheet | Low | Material slides easier, less “hang-up” |

If your wall friction drops, you often need less hopper angle to keep flow moving. That can be huge on retrofits, because you can’t always rebuild the bin. Sometimes you just need it to stop acting like a sandcastle.

Low-Friction UHMWPE Liners

A good liner does two jobs at once:

- It reduces wall friction so bulk solids can slide.

- It takes wear so your steel shell doesn’t get chewed up.

When people say “low-friction liner,” they usually mean UHMWPE or a related polyethylene grade. If you sell or spec liners, the conversation gets easy when you keep it practical:

- “Does it slide better?”

- “Does it last?”

- “Can we install it without a week of drama?”

“Does a liner fix bridging?”

Sometimes. If the bridge starts because the wall grips the material, lowering wall friction can reduce bridging risk. If the bridge starts because the outlet is too small, a liner won’t magically change physics. You might still need a bigger throat, a better feeder, or a flow aid.

Here’s a realistic “what works” cheat sheet:

| Symptom | Likely root cause | Quick check | Liner-related fix |

|---|---|---|---|

| Sudden stoppage above outlet | Arching / bridging | Probe near throat, listen for hollow zone | Lower wall friction + review outlet size |

| Material flows then quits | Wall slip problem | Tap wall, flow restarts briefly | Add low-friction liner on hopper walls |

| Center channel forms | Ratholing | Bin level drops but discharge gets weak | Liner + consider mass-flow upgrades |

| Frequent build-up on walls | Adhesion / fines / moisture | Scrape wall, see smeared layer | Choose grade + surface finish, add clean-out access |

Coal Bunker Limit Plates And Coal Hopper Liners

Coal systems are rough. They’re dusty, abrasive, and they love to pack in corners. This is why operators care about two things: flow control and wear control.

If you’re working around coal bunkers, you’ll see limit plates and liner plates used to reduce wear and reduce hang-up. On our site, you can look at the product family for Coal Bunker Limit Plates and how it ties into wear panels and bunker lining layouts.

Practical coal bunker liner points that teams actually care about

- Keep the wall slick so fines don’t “glaze” and start stacking.

- Use clean-out access because coal will surprise you, always.

- Don’t ignore fastening. A loose liner becomes a shovel project.

Installation, Fasteners, And Real-World Mistakes

A liner can be perfect on paper and still fail in the field. Installation makes or breaks it.

Fastening and fit-up keywords that matter

- Countersunk holes (so material doesn’t snag)

- Thermal expansion allowance (poly moves, steel moves less)

- Panel seams (bad seams catch product, then you get hang-up)

- Wear zones (impact areas need more thickness or backing)

Here’s a small truth: if you install a liner like a steel plate, you’ll have problems. UHMWPE needs room to breathe. Give it clearance, use the right washer stack, and don’t over-torque like you’re mad at it.

Also, plan the seams so material doesn’t “hook” on the edge. A tiny lip can start a big build-up. It sounds small, but it’s big deal, trust me.

Where “Dongxing Rubber” fits in (in a normal way)

On some retrofit jobs, teams pair UHMWPE liners with rubber parts—like sealing strips, edge protection, or skirting around transfer points.You’re not choosing plastic or rubber. You’re building a system that slides, seals, and survives.

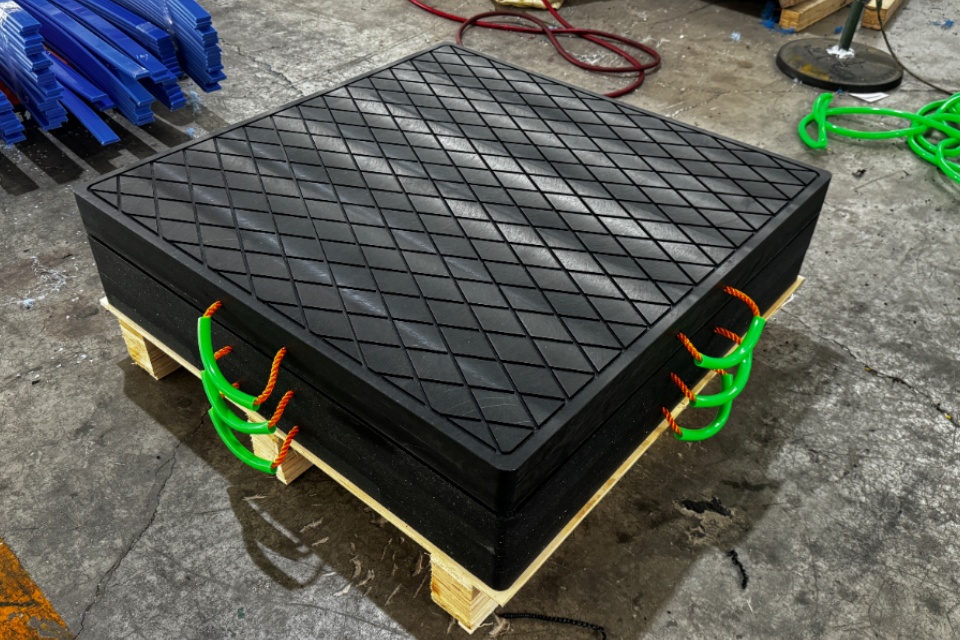

Crane Outrigger Pads And Bulk Material Yards

You might ask, “Why talk about pads in a flow article?” Because the same sites that fight bridging also fight ground failure. Mines, ports, terminals, and coal yards run both problems in the same week.

When you stabilize heavy equipment, you spread load and reduce sink. That’s exactly why Crane Outrigger Pads matter in the same industries that run hoppers and chutes. Same people. Same pain. Different failure mode.

And if your crew also builds temporary access routes, Ground Protection & Road Mats can keep rigs from chewing up soft ground. It’s not fancy. It’s just less chaos.

What To Ask Before You Buy Liners

If you want fewer surprises, ask these questions:

- What’s the material doing—free-flowing, sticky, damp, oily, hot?

- Where does it hang up—walls, corners, throat, transition?

- Do you see arching, ratholing, or both?

- Do you need wear resistance, low friction, or both?

- How will you install it—access, bolt pattern, downtime window?

If you need a fast path, start with your liner area and your worst zones. Then spec sheet type, thickness, and fastening that match your site reality. Don’t overthink it, but don’t wing it either.

If you’re buying in volume, doing OEM/ODM, or cutting custom panels, it helps to work with a manufacturer who lives in this world. We support bulk and custom builds from sample to production runs, and we answer fast—because when a bin is plugged, nobody wants to wait.

If you want, tell me your material type and the hopper style (cone, wedge, transition). I’ll map the most likely root cause and a liner layout that makes sense.