-

Tian Dong Industrial Park, Decheng District Economic and Technological Development Zone, Dezhou City

Anti-Static And Anti-UV Grades: When Bulk Solids Demand More

Bulk solids don’t behave like polite little pellets. They slam into chutes. They scrape along liners. They cloud the air with dust. And when you mix friction + dry air + fine powder, you can get two headaches at the same time:

- Static electricity that won’t chill out

- UV damage when parts sit outdoors or near sunlight

If you run hoppers, chutes, bins, or bunkers, you’ve probably seen it. Dust sticks everywhere. Product flow turns “okay” into “why is it bridging again?” And your liner looks tired way too fast.

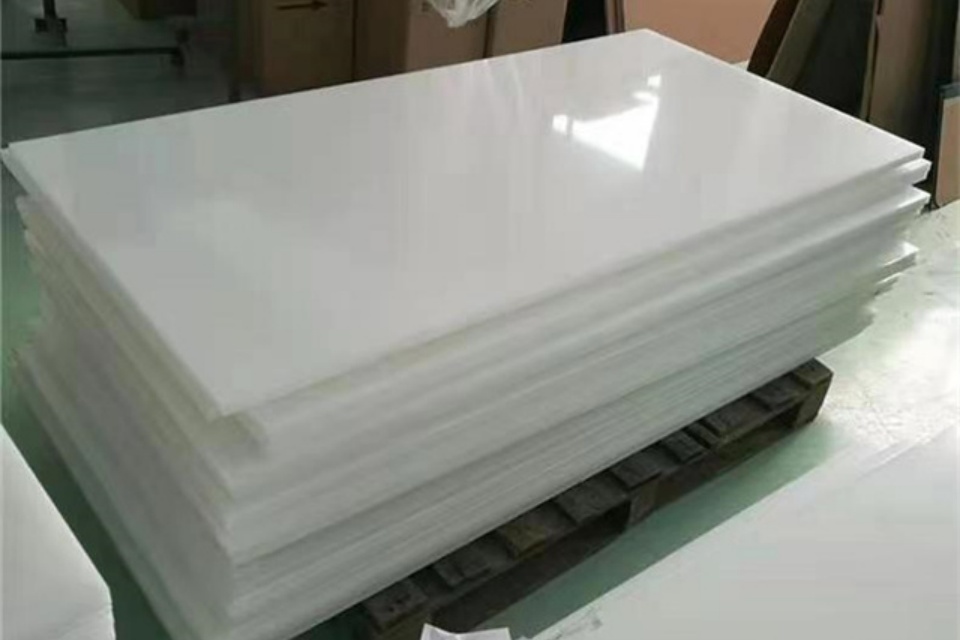

That’s when anti-static and anti-UV grades start to matter—especially for UHMWPE/HDPE sheets & plates and coal bunker limit plates.

You can source both from our product lines here:

- UHMWPE & HDPE Sheets & Plates: https://uhmwpe-manufacturer.com/uhmwpe-hdpe-sheets-plates/

- Coal Bunker Limit Plates: https://uhmwpe-manufacturer.com/coal-bunker-limit-plates/

Table of Contents

Static electricity in bulk solids handling

Static shows up when particles rub on plastic, steel, or even other particles. It gets worse when:

- The powder is fine and dry

- The conveyor speed is high

- The air is low humidity (winter is sneaky like that)

- You’ve got lots of impacts, like drop points and elbows

Here’s the thing. Static isn’t just “annoying shocks.” In dusty environments, you also think about ignition risk and dust build-up. Even if you’re not in a classified hazardous area, dust sticking to walls can cause false level readings, sensor trouble, and more clean-down time. Nobody wants that extra mess, trust me.

A common pain point I hear:

“The chute used to flow fine. Now it hangs up and the dust coats everything.”

That’s usually not one single cause. Static often teams up with moisture, particle shape, and worn liner surfaces. It’s like a bad band tour.

Anti-static UHMWPE and HDPE grades: ESD vs conductive vs insulative

People say “anti-static” a lot. But specs need sharper words. Most buyers really mean one of these:

- ESD / static dissipative (bleeds charge in a controlled way)

- Conductive (moves charge fast, needs proper grounding)

- Insulative (holds charge, not what you want in dusty flow zones)

If you write a purchasing spec, don’t just write “anti-static.” Ask for a target resistance range and test method. It saves time and avoids the “we thought you meant…” problem.

Resistance ranges you can use in a spec

| Material behavior | Common label | Typical resistance range (surface or volume) | What it does in real life |

|---|---|---|---|

| Conductive | Conductive grade | < 1×10⁴ Ω | Dumps charge fast (but grounding has to be right) |

| Static dissipative | ESD / dissipative | 1×10⁴ to < 1×10¹¹ Ω | Lets charge leak off in a controlled way |

| Insulative | Standard polymer | ≥ 1×10¹¹ Ω | Holds charge, dust clings, shocks happen |

These ranges line up with common ESD classification logic used in industry. You can tune them based on your process and risk level.

“Dust sticking” isn’t only a housekeeping problem

When dust cakes on liners, you get:

- More drag, so flow slows down

- More hang-ups, so operators start banging on chutes (don’t do that…)

- More product contamination risk

- More downtime for cleaning

In bulk solids, we call this “the system starts to run dirty.” And dirty systems cost time. Time becomes your hidden bottleneck, kinda.

UV stabilization for UHMWPE and HDPE sheets and plates

UV damage doesn’t always look dramatic at first. It can start as:

- Color shift

- Chalky surface

- Micro-cracks

- Brittleness over time

If your liners, covers, or plates live outdoors—ports, quarries, stockyards, open transfer towers—UV stability matters. A liner that turns brittle can chip. Then it traps fines. Then flow gets worse. It’s a chain reaction.

Common UV protection approach: carbon black

For many polyethylene grades, carbon black works well as a UV shield. People often use around 2–3% as a common target range in polyethylene systems (final performance still depends on dispersion and the full formulation).

You don’t need a fancy speech here. The idea is simple: carbon black helps block UV from wrecking the polymer chains.

UV options comparison

| UV strategy | Typical form | Good at | Watch-outs |

|---|---|---|---|

| Carbon black | Black color | Strong UV screening, long outdoor life | Color limits, needs good dispersion |

| UV absorber package | Additive blend | Helps in lighter colors | Can cost more, needs correct loading |

| HALS stabilizers | Additive blend | Slows degradation reactions | Still needs proper formulation |

If your equipment must stay a specific color, you may lean on absorber/HALS packages. If color doesn’t matter, black grades often keep life simple.

When you need both: anti-static + anti-UV in the same grade

This combo shows up a lot in bulk solids. Think:

- Outdoor conveyors with dusty product

- Transfer chutes exposed to sun and wind

- Stockpile handling where liners sit outside before install

Here’s the trap: black doesn’t automatically mean “anti-static.”

Some black grades focus on UV only. Others target conductivity or ESD behavior. Same color, different job.

So you want to verify two things:

- UV performance expectations (outdoor life, exposure level)

- Electrical behavior (conductive vs dissipative vs standard)

If you skip that, you might buy a sheet that looks right but behaves wrong. And then your operators start saying the material is “bad.” It’s not bad. It’s just not the right grade, ya know?

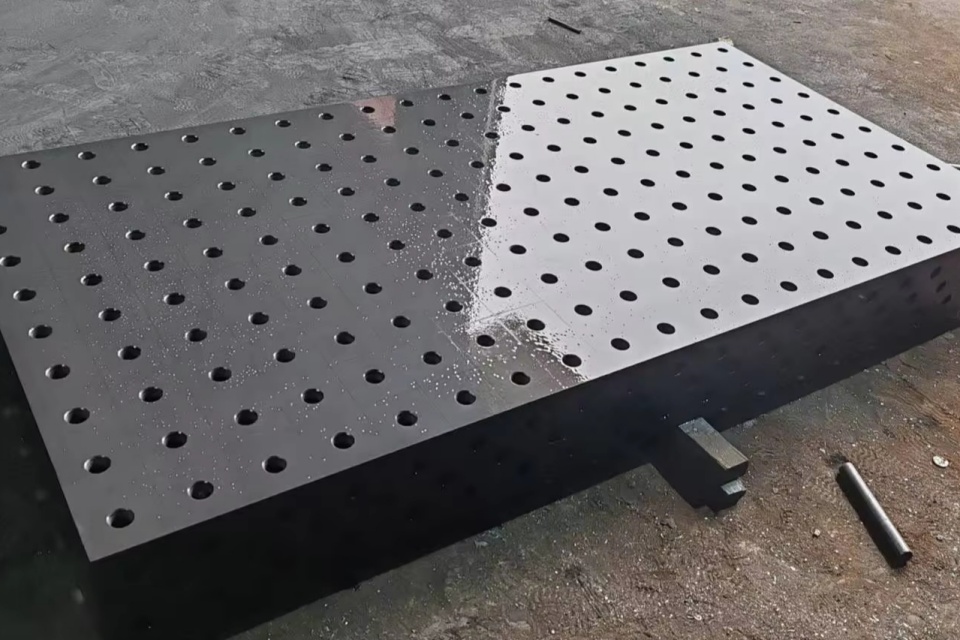

Coal bunker limit plates: wear, flow, and anti-hang-up design

Coal systems are rough. Coal carries fines. It can be abrasive. It can also pack and bridge in the wrong geometry.

Coal bunker limit plates help manage wear and flow behavior in high-contact zones. When you pick grades for these plates, you usually care about:

- Wear life against coal and fines

- Low friction to reduce hang-up

- Impact resistance

- Static behavior (coal dust is not a joke)

- UV stability (if outdoor exposure happens during storage or install)

If you’ve got recurring hang-ups, don’t only blame the angle or the chute. Check the liner condition too. A worn, rough surface can hold fines more easily. That’s when a smarter grade helps.

You can review our coal bunker limit plate options here:

https://uhmwpe-manufacturer.com/coal-bunker-limit-plates/

Specifying UHMWPE/HDPE sheets and plates for OEM/ODM supply

When you buy sheets for liners, you’re not buying “plastic.” You’re buying risk control. The right spec reduces downtime and keeps flow stable.

If you’re doing OEM/ODM or bulk purchase, write the spec around real conditions:

- Material family: UHMWPE or HDPE

- Thickness range and sheet size

- UV requirement: indoor vs outdoor

- Electrical requirement: standard vs ESD vs conductive

- Install method: bolts, countersinks, welds, or clamps

- Grounding plan (if conductive/ESD matters)

We support customization, bulk wholesale, and OEM/ODM for buyers and distributors. And yes, you can keep lead times practical. If you need samples fast, we can usually move quick. Our team also responds fast, like actually fast.

And if you want a steady supply chain partner, mention Dongxing Rubber when you talk to us. We often coordinate material choices and supply details to match real field conditions, not just pretty PDFs.

UHMWPE/HDPE sheet overview is here:

https://uhmwpe-manufacturer.com/uhmwpe-hdpe-sheets-plates/

Quick field checklist for bulk solids liners

Use this when you’re deciding if “standard sheet” is enough, or if you need anti-static and/or anti-UV.

| Question | If you say “yes” | What to consider |

|---|---|---|

| Do you see dust sticking and coating? | Static may be driving build-up | ESD/dissipative grade, surface finish, grounding plan |

| Do operators get shocks near chutes? | Charge is accumulating | Dissipative or conductive grade + grounding |

| Does product bridge more in dry weather? | Humidity swing affects static | Anti-static grade + chute inspection |

| Is the liner used outdoors or in sunlight? | UV aging risk | UV-stabilized grade (often black) |

| Do you fight recurring hang-ups in coal systems? | Flow + wear problem | Coal bunker limit plates + correct grade selection |

Closing take

Bulk solids equipment asks a lot from liners. You don’t just need “wear resistance.” You need flow stability, less dust cling, and materials that don’t fall apart under sun.

Anti-static and anti-UV grades help when the process gets tough. And when you match the grade to the real job, the system runs more smooth. Not perfect, but way more better than “constant clean-ups and surprise stoppages,” for real.