-

Tian Dong Industrial Park, Decheng District Economic and Technological Development Zone, Dezhou City

UHMWPE Liners In Chutes And Hoppers: Angle Of Repose Matters

You can build a chute that looks “steep enough” on paper. Then the first wet shift hits, and the chute starts hanging up like it’s mad at you.

That’s the real fight in bulk handling. Material doesn’t care about your drawing. It cares about gravity, friction, and how the particles behave when they get tired, damp, or crushed.

So yes, angle of repose matters. But if you stop there, you’ll still get hang-up, rat-holing, bridging, and random clean-out jobs at 2 a.m.

Let’s talk about it in plain English, with real plant scenes. And we’ll keep it practical for liners, especially UHMWPE liners and when nylon sheets also make sense.

Table of Contents

Angle Of Repose In Bulk Material Flow

Angle of repose is the slope a pile makes when material drops and settles. It’s easy to picture. Dump coal on the floor. The pile forms a cone. That angle is the angle of repose.

Here’s the catch: it changes a lot.

- Moisture changes it.

- Fines content changes it.

- Particle shape changes it.

- Even how you poured it changes it.

So the angle of repose is a starting clue, not a final design rule.

Typical Angle Of Repose Ranges You’ll See On Site

These are common field ranges people use as a rough guide (values vary by condition, test method, and moisture). If you want the real number, you test your exact material.

| Bulk material (example) | Typical angle of repose range (degrees) | What usually pushes it higher |

|---|---|---|

| Coal (run-of-mine / mixed) | 27–45 | Moisture, fines, compaction |

| Dry sand | 30–35 | Moisture, angular grains |

| Crushed limestone | 32–40 | Fines, rough particles |

| Grain (corn/wheat) | 23–30 | Broken kernels, humidity |

| Cement / fine powder | 35–50 | Humidity, aeration changes |

What this table tells you: if you pick one “book number,” you’ll miss the real world. That’s why chutes that “should” flow still plug.

Chute Design: Self-Cleaning Angle Beats “Looks Steep”

In chutes, you don’t just want flow. You want self-cleaning flow. That means material keeps moving and doesn’t build a shelf.

A simple rule people use in the field:

- Chute wall angle should exceed the material’s tendency to pile on that surface.

- Many engineers add a small margin (often a few degrees) for safety because conditions drift.

But don’t confuse two things:

- Angle of repose = pile in open air

- Build-up angle on a liner = pile behavior on that wall material

Those can be very different.

The Wall Friction Angle Is The Real “Gatekeeper”

When operators say, “This chute is sticky,” they’re really saying: wall friction is too high, so the material slows down and parks itself.

That’s why liners matter. A low-friction liner can turn a bad day into a normal day.

Hopper Flow: Mass Flow vs Funnel Flow (And Why You Care)

Hoppers fail in predictable ways. They don’t fail because people are dumb. They fail because the hopper runs in the wrong flow pattern.

- Mass flow: all material moves. First-in, first-out. Less stale material.

- Funnel flow: a channel forms in the center. Sides sit still. That’s where you get trouble.

Bridging, Ratholing, And “Why Won’t It Discharge?”

If you’ve seen these, you know:

- Bridging (arching): material forms a stable arch over the outlet.

- Ratholing: a narrow flow tube forms, then collapses, then bridges again.

- Caking: material sticks and hardens against the wall.

Angle of repose shows part of the story, but hopper design depends more on wall friction and internal friction. That’s why serious designs use measured friction data, not just repose.

And yeah, a 60° cone isn’t magic. Some materials still hang up like crazy.

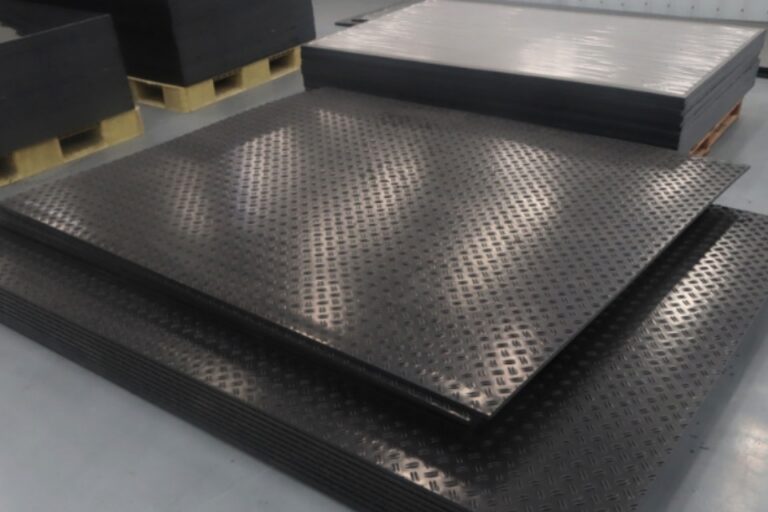

UHMWPE Liners In Chutes: Reducing Hang-Up And Wear

UHMWPE liners get picked for a reason:

- Low sliding friction (helps stop build-up)

- Great abrasion resistance (helps stop wall wear)

- Impact toughness (helps when lumps hit hard)

Here’s a common plant scene:

Your chute runs fine on dry days. Then the rain comes. Coal gets tacky. Fines smear. The chute starts building a “ski jump” of stuck material near the discharge.

A UHMWPE liner often helps because it reduces the wall drag. The material keeps moving. Less hang-up. Less shovel work.

Where UHMWPE Liners Help The Most

- Transfer points with low velocity

- Chutes with shallow angles

- Materials with fines + moisture

- Areas with repeated build-up and washdown

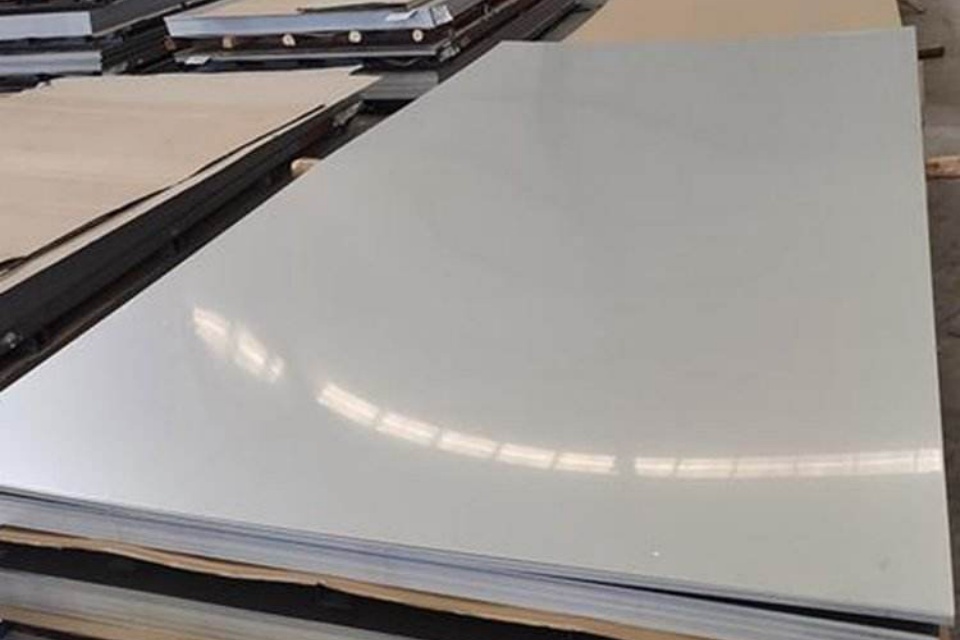

Don’t Skip The Details: Fasteners And Seams

Even the best liner can fail if you install it rough.

Watch for:

- Proud bolt heads (they act like hooks)

- Bad seams (they catch fines)

- Unsupported liner edges (they curl and catch product)

If you want smoother flow, you want a smoother wall. Simple.

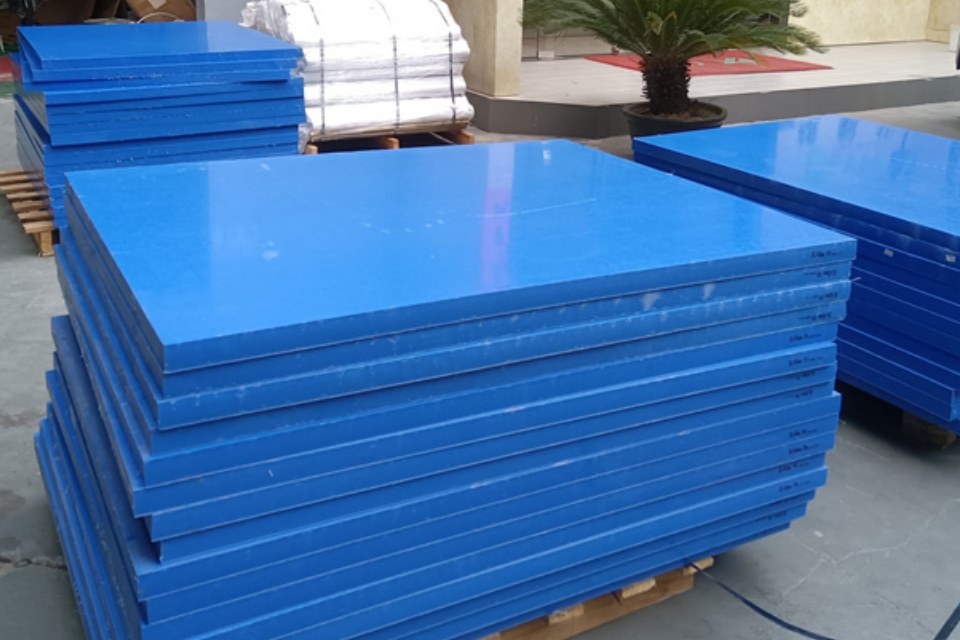

Nylon Sheets For Liners: When They’re A Better Fit

UHMWPE is not always the right call. Sometimes nylon sheets are a smarter fit for a specific job, especially when you want:

- Higher stiffness

- Better temperature behavior in some ranges

- A different wear pattern under certain loads

Nylon vs UHMWPE For Chutes And Hoppers (Quick Comparison)

| Liner sheet type | What it’s good at | Where it can struggle |

|---|---|---|

| UHMWPE liner | Low friction flow, abrasion, impact | Higher thermal expansion, needs good fastening plan |

| Nylon sheet | Stiffer, good mechanical strength | Can absorb moisture, friction may be higher vs UHMWPE in some cases |

Practical Decision Table: Angle, Friction, And Fix Options

| Symptom on site | Likely cause | What to do (fast) | What to do (right) |

|---|---|---|---|

| Hang-up near chute discharge | Wall friction too high, angle too low, seams catching | Clean + inspect seams/bolts | Switch to low-friction liner (UHMWPE), smooth fastening, check chute angle |

| Hopper discharges then stops | Funnel flow, arching at outlet | Poke / vibrate (short-term) | Review hopper flow pattern, increase outlet, pick liner by friction data |

| Ratholing then sudden collapse | Material cohesive, walls too “grabby” | Operator babysitting | Improve wall surface, reduce friction, consider mass flow geometry |

| Wear grooves and thin spots | Abrasion + impact | Patch + rotate liners | Use wear-resistant liner, fix impact point, add sacrificial sections |

Real-World Scenarios (The Stuff Buyers Actually Ask)

Scenario 1: Coal chute in a power plant

They tell you: “It flows most days, then jams in rain.”

That’s classic. Moisture bumps up cohesion and makes fines stick. If they only used angle of repose from a chart, they’re living on luck. A UHMWPE liner can reduce sticking and keep flow moving.

Scenario 2: Quarry hopper feeding a crusher

They tell you: “We get sudden stops and big surges.”

That smells like funnel flow plus bridging. You can’t fix that with angle alone. You need outlet and wall friction thinking. A liner helps, but the geometry still matters.

Scenario 3: Food or grain handling

They tell you: “It’s clean, but it still forms a cone and won’t empty.”

That’s flow pattern again. Sometimes a liner helps. Sometimes the hopper needs redesign. Many teams start with a liner because it’s faster and cheaper than steel work (no numbers here, just truth).

The Takeaway: Angle Of Repose Matters, But It’s Not The Boss

Angle of repose matters because it’s a quick signal. It tells you when you’re asking material to do something it hates.

But the real driver is material + wall friction + flow pattern.

So if you want fewer plug-ups:

- Use angle of repose as a first filter

- Then focus on friction and surface behavior

- Pick the liner that matches the job: UHMWPE & HDPE sheets for slide and wear, Nylon Sheets when stiffness and strength matters

- Install it clean. Bad seams ruin good material, every time.

And if you’re buying from a High-Performance Engineering Plastic Products Manufacturer, you probably want the full package: custom builds, bulk wholesale, OEM/ODM, quick response, and steady lead times. That’s the whole point.