-

Tian Dong Industrial Park, Decheng District Economic and Technological Development Zone, Dezhou City

Retrofitting Steel-Faced Fenders with UHMWPE Pads

You’ve probably seen it. A steel-faced fender does its job, but the ship still leaves with ugly scuff marks. The berth crew hears that nasty squeal during contact. The hull paint looks “burnt” in one spot. And after a few months, your maintenance team is chasing the same problems again.

So you start asking a simple question: Can we keep the steel strength, but make the contact surface kinder and smoother?

That’s where UHMWPE pads come in. Retrofitting steel-faced fenders with UHMWPE pads isn’t fancy. It’s practical. It’s the kind of upgrade you do when you want fewer complaints, less rework, and a fender line that behaves more predictably.

Below, I’ll walk you through the “why” and the “how,” with real shop-floor thinking, not brochure talk.

Table of Contents

Steel-Faced Fenders and Real Berthing Problems

Steel-facing gives you a hard, durable front. But in real berthing scenes, it can create pain points:

- High friction contact: The ship doesn’t just push in. It also slides a bit. Tides, wind, and thrusters make that happen.

- Stick-slip: That grab-and-release motion makes noise and can spike side loads. It feels like the ship “jumps” on the fender.

- Coating damage and marking: You get scuffs, streaks, and sometimes deep paint wear.

- Maintenance gets annoying: Steel panels can wear unevenly. Once the surface gets rough, it gets worse fast.

UHMWPE Fender Pads and Why Retrofit Makes Sense

UHMWPE (Ultra-High Molecular Weight Polyethylene) pads work because they change the contact behavior at the front face.

What you usually get after a retrofit:

- Lower friction, so ships slide more smoothly.

- Non-marking contact, so you reduce visible streaks.

- Better wear behavior, because UHMWPE resists abrasion well.

- Replaceable surface, so you don’t rebuild the whole fender. You swap pads.

And here’s the big win: you keep your steel structure, but you upgrade the “touch point.” That’s often the smartest place to spend effort.

Coefficient of Friction and “Side Load Headaches”

Let’s keep this simple. Friction decides how much the ship “drags” across the face.

Here’s a practical comparison you can use when explaining the retrofit to a port manager:

| Contact Pair (Typical) | Typical Friction Level | What You Feel On the Dock |

|---|---|---|

| UHMWPE on Steel | ~0.2 | Smoother slide, less squeal |

| Rubber on Steel | ~0.7 | More grab, more stick-slip |

When friction drops, the ship can move a bit without fighting the fender face. That often means less “weird” side loading on chains, brackets, and anchors. It won’t fix bad mooring, of course. But it helps the whole system act more calm.

And yeah, you’ll still hear dock guys say: “This berth is a bit spicy today.” Wind and swell still exist. The pad just makes the contact surface less stubborn.

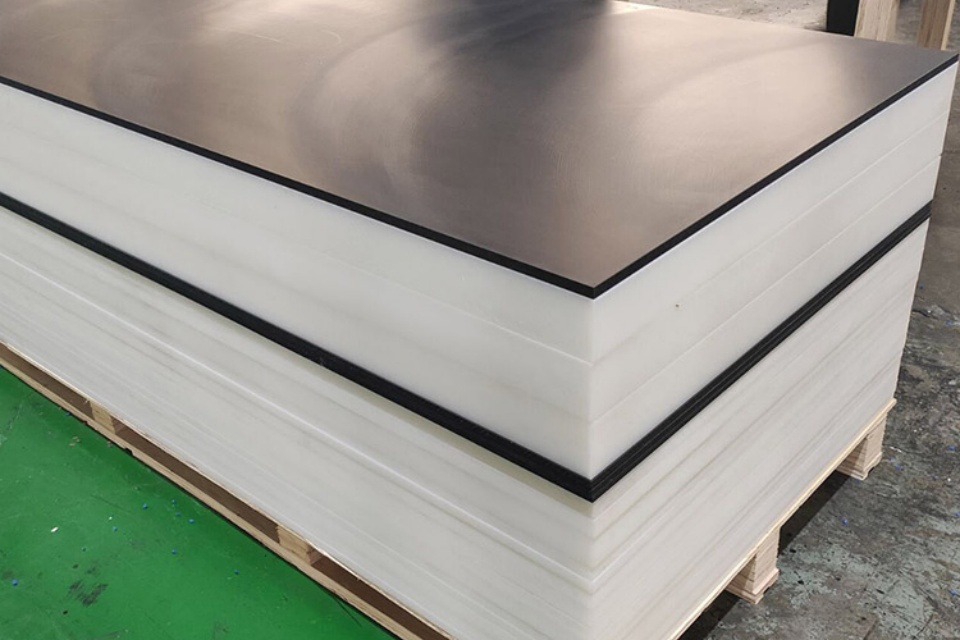

UHMWPE Pad Thickness, Wear Allowance, and Duty Level

A lot of retrofits fail for a boring reason: the pad spec doesn’t match the duty.

If you under-size the pad, it wears too fast. If you overbuild it, you waste time and money (and your install gets harder).

A common way to spec pads is by duty level and planned wear allowance:

| Duty Level | Typical Pad Thickness (t) | Typical Wear Allowance (W) | Typical Bolt Size Range |

|---|---|---|---|

| Light Duty | ~30 mm | ~3–5 mm | M16 |

| Medium Duty | ~40–50 mm | ~7–15 mm | M16–M20 |

| Heavy Duty | ~60–80 mm | ~15–32 mm | M24–M30 |

| Extreme Duty | ~90–100 mm | ~25–40 mm | M30–M36 |

Wear allowance is the “extra” you plan to lose over time. It’s like tire tread. You don’t want to run it to zero.

A quick rule that works in real life:

If your berth sees frequent contact, higher approach angles, or rough hull conditions, don’t pick the light spec just because it’s easy. You’ll regret it later.

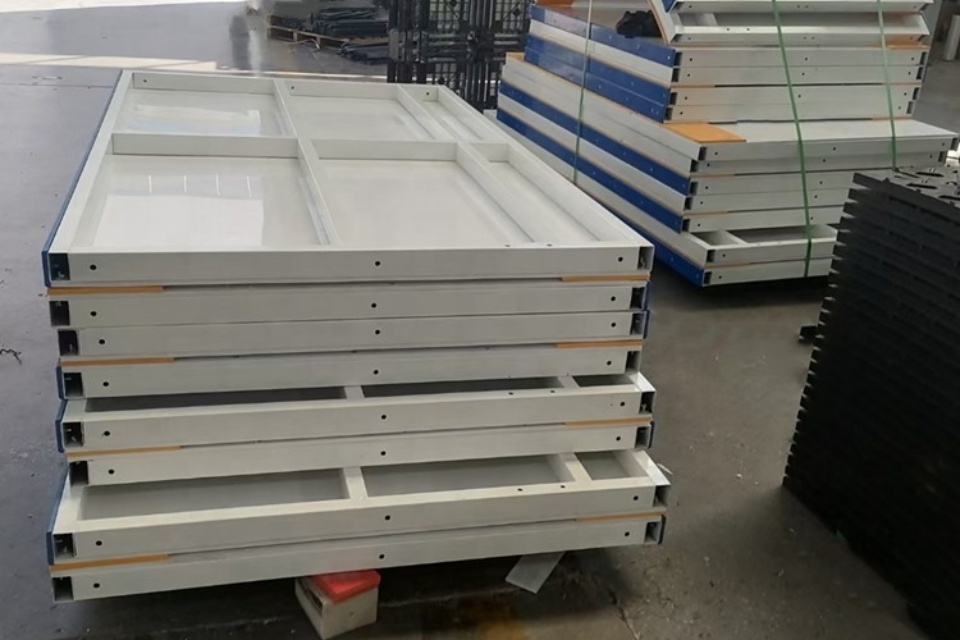

Bolted UHMWPE Facing Pads and Fastener Details

Most retrofit jobs use bolted-on UHMWPE pads. That’s good because it keeps the system serviceable. But details matter.

Countersunk holes and flush heads

You want a smooth face. If bolt heads stick out, they become wear points and can mark the hull. Countersunk holes help keep the front clean.

Bolt pattern and backing support

A pad needs proper support behind it. If the backing plate flexes, you’ll get localized stress and faster wear. Your pad will look “cupped” over time.

Corrosion and isolation

Steel + marine air + water = corrosion. So the fastening stack-up needs attention. People skip this step and then act surprised later, you know?

Thermal movement

Plastic moves more than steel with temperature. So you plan holes and clearances so the pad doesn’t bind up. If it binds, it can crack or “grow” into weird shapes. Not fun.

I’m not saying every job needs perfection. But you do need a clean, consistent install. Otherwise the retrofit feels “cheap.”

Retrofit Installation Sequence and Downtime Control

If you’re running a busy berth, downtime is the real enemy. A simple sequence helps:

- Survey the existing steel face: measure flatness, corrosion, weld spatter, and sharp edges. Grind the bad stuff.

- Confirm pad layout: decide pad segmentation (big panels vs smaller sections). Smaller sections are easier to replace later.

- Dry-fit pads: check hole alignment and countersink depth.

- Install with controlled torque: don’t crush the pad. Too tight looks “strong,” but it can cause stress and creep.

- Edge finishing: chamfer edges if needed. Sharp edges catch and wear faster.

- Commissioning check: walk the line and confirm there’s no proud hardware, no gaps, no rocking pads.

This isn’t complicated work. But it is picky work. If your crew rush it, the pads will tell on you later.

Ice Rink Dasher Boards and the Same UHMWPE Logic

You might wonder why I’m bringing up Hockey (Ice) Rink Dasher Boards in a fender article. Simple: the problem pattern is similar.

In an ice rink, you need boards that handle impact, stay clean, and don’t chew up skates or gear. You also want replaceable facing because collisions happen every day. That’s basically the same “front-face thinking” as a fender retrofit.

So if you already buy UHMWPE for marine pads, it’s natural to source UHMWPE for rink systems too. Same material mindset. Different scene.

If you work in rink projects, take a look at your own category page here:

https://uhmwpe-manufacturer.com/hockey-ice-rink-dasher-boards/

OEM/ODM Supply Notes for Wholesalers and Project Buyers

If you’re buying for projects or bulk resale, here’s what usually matters most:

- Consistent material grade: don’t mix “similar” plastics and call them the same. You’ll get uneven wear.

- Stable machining quality: clean countersinks, clean edges, repeatable hole spacing.

- Pack-and-ship protection: pads get dinged easily if someone throws them around.

- Fast response: when a berth is down, nobody wants a slow email loop.

If you’re building a bigger catalog, it also helps when one supplier can cover multiple lines, like Ground Protection & Road Mats plus ice rink projects, without changing how you spec or buy.

And when a project includes both rubber and plastic parts, it’s normal to coordinate with a rubber partner too. That’s where Dongxing Rubber fits naturally in the conversation—rubber fender bodies plus UHMWPE facing pads can be a clean combo for many docks.

Closing Thought

Retrofitting steel-faced fenders with UHMWPE pads isn’t about chasing trends. It’s about fixing the front-face behavior where the ship meets the dock.

If you want smoother berthing, fewer marks, and easier maintenance, the retrofit makes sense. Keep the steel. Upgrade the contact. Plan thickness and wear allowance like you mean it. Install it clean, not sloppy.

And if you also sell UHMWPE into ice rink projects, you already understand the core idea: a replaceable UHMWPE face saves headaches later. That logic travels well—from rink boards to quay walls.