-

Tian Dong Industrial Park, Decheng District Economic and Technological Development Zone, Dezhou City

Low-Friction Marine Facing: Protecting Vessels And Quay Walls

You’ve seen it. A ship comes in a little hot. Wind pushes. Tide pulls. The hull “walks” along the berth and the quay wall takes the beating. Paint scuffs first. Then you start seeing steel shine-through, concrete spalls, and bent hardware. It’s annoying, and yeah, it gets expensive fast (no, I won’t throw random cost numbers at you).

That’s why low-friction marine facing matters. In plain terms, you add a slick, tough layer—often UHMW-PE—to the part of the fender or quay that touches the vessel. The ship slides instead of grabs. Less tearing. Less grinding. Less drama.

Below I’ll break down the key arguments, with real dockside scenes, a data table, and practical tips you can use on your next berth job.

Table of Contents

Low friction UHMWPE marine facing reduces shear during berthing

When a vessel lands on the fender, two things happen at the same time:

- The fender takes the hit (energy absorption).

- The hull keeps moving sideways (side load + “scrub” movement).

If the contact surface has high friction, the hull doesn’t slide. It sticks. That stick turns into shear force. Shear force is the sneaky one. It doesn’t look scary in a brochure, but it rips coatings, drags fittings, and chews up rubber faces.

A low-friction UHMWPE facing flips that story. The hull can slip along the contact zone. You cut the shear. You also cut the “grab-and-release” jerks that make crews nervous.

Think of it like this: would you rather drag a heavy box across concrete, or across a smooth plastic sheet? Same box. Very different fight.

UHMW-PE fender facing pads protect hull coatings and quay wall structures

A lot of berth damage starts small:

- A few scrape marks.

- A torn patch of anti-fouling.

- A sharp corner on a steel frame that kisses the hull one time too many.

Low-friction facing works like a buffer skin. It takes the rub marks. It spreads contact. It keeps hard steel edges away from the hull.

On the quay side, it helps too. If you run a steel-on-steel or steel-on-concrete contact by mistake (bad alignment, worn rubber, missing pad), you get fast damage. A facing pad gives you a safer “first contact” surface.

One more point people forget: UHMWPE doesn’t just slide well. It also fights wear. That matters when you’ve got frequent calls, tight schedules, and tugs pushing ships into place all day.

Friction coefficient table: UHMWPE vs rubber vs steel for quay wall protection

Here’s a simple comparison you can paste into your spec sheet discussion. Values vary by surface finish, load, wetness, and temperature, so treat these as typical published ranges, not a lab promise.

| Contact material (facing) | Typical friction coefficient (µ) | What you usually see on site | Good fit for |

|---|---|---|---|

| UHMW-PE (UHMWPE) | ~0.10–0.20 | Smooth sliding, less “snatch” | Fender facing pads, quay wall rubbing strips |

| HDPE | ~0.20–0.30 | Slides, but not as slick as UHMWPE | Light-to-medium scrub zones |

| Nylon | ~0.20 | Can slide well, but watch water uptake | Some guides, rollers, specialty spots |

| Rubber (plain contact) | ~0.60–0.80 | High grab, higher shear | Good for grip, not for sliding faces |

| Steel (bare) | ~0.40–0.60 | Scrapes fast, risky for coatings | Avoid as direct contact surface |

| Timber | ~0.30–0.50 | Changes with wet/dry, wears uneven | Older berths, temporary fixes |

If you want one takeaway: lower friction usually means lower shear, and that’s a big reason ships and quay walls last longer.

Quay wall protection needs system thinking: rubber fenders + UHMWPE facing pads

Don’t treat facing as a “sticker” you slap on at the end. It works best when you design it as part of a marine fender system:

- Rubber unit handles energy (compression).

- Steel frame carries load.

- UHMWPE facing handles sliding and wear.

- Fasteners and backing plates keep everything tight.

If you skip system thinking, you get the classic failures:

- Pads crack because bolt spacing is off.

- Pads dish or creep because backing support is weak.

- Bolts loosen because the berth sees constant vibration and scrub.

- Pads pop off and disappear into the sea (yep, it happens).

So when you spec it, ask: Where does the side load go?

If the answer is “into two bolts and hope,” you already know it’s wrong.

Real-world berthing scenarios where low-friction facing earns its keep

Crosswind berthing and tidal range “walk”

You get a crosswind day. The pilot lands, then the vessel keeps drifting along the face while lines come tight. That side motion is the scrub zone. Low-friction facing keeps that movement smooth.

Tug wash and micro-movements

Even when the ship looks steady, tug wash and engine pulses cause tiny movements. Over weeks, those tiny moves grind surfaces down. Low-friction facing turns grinding into sliding. It’s not magic, but it helps a lot.

Ro-Ro ramps and repeat contact points

Ro-Ro berths hit the same spots again and again. If you don’t control friction, you’ll see wear tracks and coating loss in the same band every visit. Facing pads act like a replaceable wear layer.

Installation and fastening details for UHMWPE fender facing pads

You don’t need fancy talk here. You need basics done right:

- Use a proper backing plate or support so the pad doesn’t “oil can.”

- Keep bolt holes clean and aligned. Misalignment makes stress points.

- Add countersinks/counterbores correctly so bolt heads don’t become sharp hull contact points.

- Plan for thermal movement. Plastics move more than steel, so allow a little breathing room.

- Seal and protect fasteners. Marine corrosion doesn’t play nice.

Also, don’t ignore edges. A small bevel or radius often saves you from “edge bite” marks on hull coatings.

Maintenance and inspection checklist for marine facing pads

Here’s a quick field checklist you can hand to your team:

- Look for missing pads or loose hardware (obvious, but it’s common).

- Check for deep grooves, cracks, or chunks torn out.

- Inspect bolt heads: any proud metal becomes a hull scratch tool.

- Watch for pad creep or distortion (sign of bad support or high side load).

- Replace damaged pads early. “Run it a bit longer” usually ends badly.

And yes, pads are often not worth “repair.” If it’s torn up, swap it. Simple.

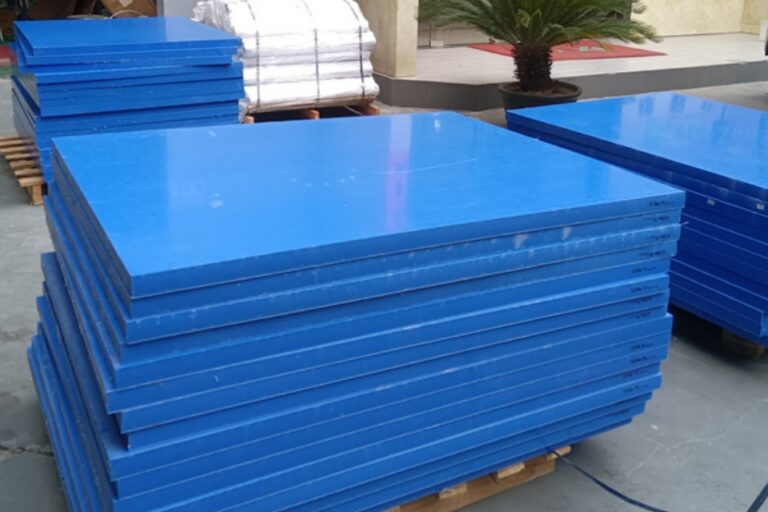

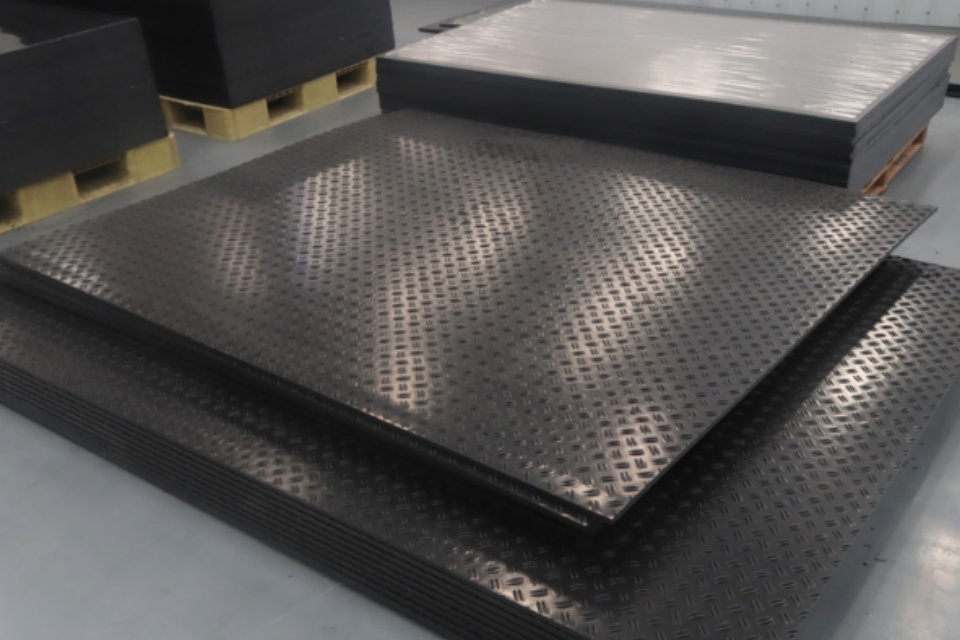

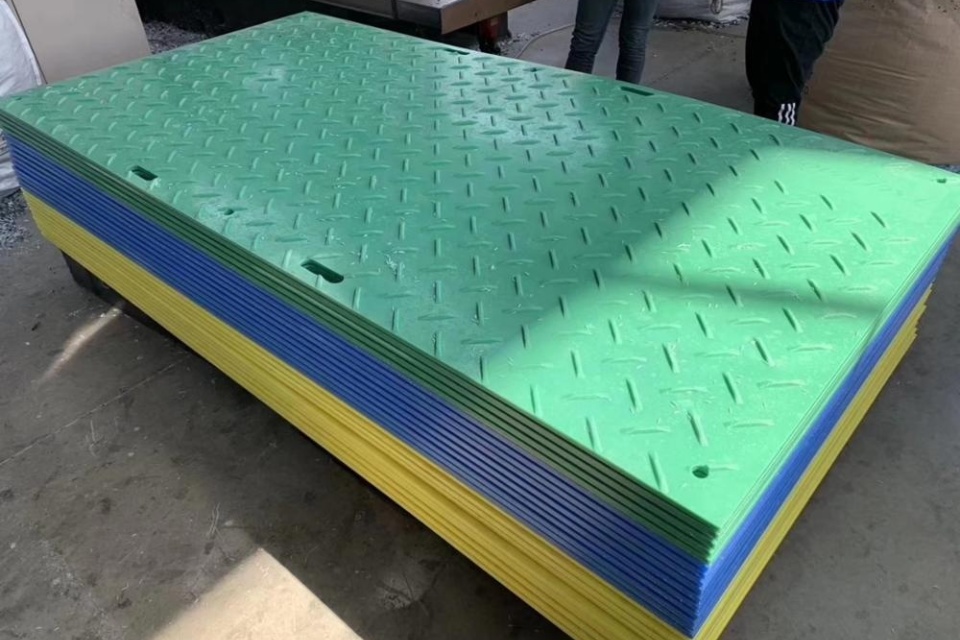

Where ground protection mats fit into marine maintenance jobs

Now the practical dock work angle. When you install or replace facing pads, you often bring in lifts, cranes, or forklifts onto rough ground near the berth. That ground can be soft, wet, or uneven. You don’t want equipment sinking, or leaving a mess that shuts the berth down.

That’s where ground protection mats make the job smoother. If you’re staging gear, laying a temporary road, or protecting pavement, check the mats category here):

- https://uhmwpe-manufacturer.com/ground-protection-road-mats/

- https://uhmwpe-manufacturer.com/dura-mats/

You can use mats as a quick “work lane” for lifts and pallet moves. It keeps the crew moving. It also reduces the chance you damage the site while you’re trying to protect the quay wall. Kind of ironic, right?

OEM/ODM marine facing and supply notes for bulk buyers

If you buy in volume, you already know the pain points: lead times, inconsistent machining, and pads that don’t match the drawing when they arrive. That’s why many berth owners and wholesalers ask for OEM/ODM support, stable batches, and fast response.

We build engineering plastic products for bulk buyers and project work. That includes UHMWPE/HDPE parts, and yes, job-site support products like mats. You can also loop in partners like Dongxing Rubber when you need the full fender package (rubber body + facing + hardware). It’s a clean way to stop juggling five suppliers who blame each other.

Sources you can cite (names only, no links)

- PIANC guidance on fender systems and UHMW-PE facing manufacturing topics

- Major fender manufacturers’ technical notes on UHMW-PE facing pads, wear, and replacement practice

- Published material references comparing friction behavior of UHMWPE, rubber, steel, and timber

- Academic summaries of UHMWPE wear/friction and chemical resistance behavior

If you want, paste your target port type (container, Ro-Ro, tanker, ferry) and the berth setup (pile, dolphin, solid quay). I’ll tailor the scenarios and the checklist to match your exact use case.