-

Tian Dong Industrial Park, Decheng District Economic and Technological Development Zone, Dezhou City

Uhmwpe Fender Pads Vs Rubber-Only Fenders: When To Combine

If you run a port, yard, or small jetty, you dont just care about theory. You care about paint damage, angry captains, and fenders that fail in the middle of peak season. In this talk we look at UHMWPE fender pads vs rubber-only fenders, and more important, when you should combine them.

I’ll keep it simple, but we still use real port language: berthing energy, reaction force, hull pressure, all that stuff.

Table of Contents

UHMWPE Fender Pads: Low-Friction Sliding Surface

UHMWPE fender pads are not the main shock absorber.

They are the sliding skin on the front:

- Very low friction, ship can slide along the berth.

- High wear resistance, no rot, no rust.

- Gentle on expensive hull coatings.

Most pads are machined from UHMWPE or HDPE sheets and plates, like the products you see in your own category “UHMWPE HDPE Sheets & Plates” (for example UHMWPE HDPE sheets & plates).The pad bolts to a steel fender panel or sometimes direct to a rubber block.

So in short:

Rubber body = energy absorption

UHMWPE pad = controlled sliding and wear layer

If you forget this, design go wrong fast.

Rubber-Only Fenders: Energy Absorption And Grip

Rubber fenders by themself do two jobs:

- Absorb berthing energy – cone, cell, arch, D-fenders, all handle impact and keep reaction force inside the safe window.

- Provide high friction – the hull “sticks” more to the face, which can help in swell or where you dont want vessel walking along the quay.

Typical behaviour:

- High friction → more grip, more damping.

- But also more paint wear, more local pressure hot spots, and sometimes higher shear loads on anchors and chains.

Rubber-only systems still work well for:

- Small fishing ports and river jetties.

- Tug and barge berths.

- Short dolphins where ship does not travel far along the face.

For heavy traffic, big ships or fancy hull coating, rubber-only starts to feel a bit old-school.

Side-By-Side Comparison: Friction, Wear, Maintenance

| Aspect | UHMWPE Fender Pad Facing | Rubber-Only Fender Face | Combined System (Rubber + Panel + UHMWPE Pads) |

|---|---|---|---|

| Main role | Low-friction sliding surface, wear layer | Energy absorption + high friction contact | Energy absorption + low-friction contact + load spreading |

| Energy absorption | Very low, not the shock absorber | High, core function of rubber unit | High (rubber body), evenly spread by steel panel |

| Typical friction | Around 0.1–0.2 vs hull paint (very “slippy”) | Often 0.6–0.8 vs concrete or paint (grippy) | Hull sees UHMWPE friction, structure sees rubber performance |

| Hull coating impact | Gentle, less scratching and chipping | More scuffing, faster paint damage | Lowest coating damage over life cycle |

| Wear & lifetime | Very good abrasion resistance, easy to change pad only | Rubber face can crack, age, tear, change means big work | Rubber body protected, usually only pads change during life |

| Motion in swell | Ship slides easier, needs chains/stoppers to control travel | Ship “sticks” more, extra damping | Tunable with chain sets, layout and pad area |

| Typical use | Quay walls, fender panels, piles, sliding strips | Small berths, tugs, barges, simple quay | Container, bulk, tanker, Ro-Ro, heavy berths |

You dont need exact numbers, just keep the relative trend: UHMWPE = low friction, rubber-only = high friction.

Real Berthing Scenarios: Where Each Option Fits

Scenario 1: Small River Pier Or Fishing Harbor

Picture a 1,000–2,000 DWT coaster or fishing boat:

- Berthing speed is low.

- Fenders are simple arch or D-type.

- Budget is tight.

- Owner dont worry too much about a few paint marks.

Here a rubber-only fender line is fine.

High friction helps hold the boat in place when current or swell pushes. Crew just want something robust they can hit all day.

UHMWPE pads might be “nice to have”, but they aren’t mandatory.

Scenario 2: Container Berth With High Berthing Energy

Now jump to a busy container terminal:

- Larger ships, higher berthing energy.

- Expensive hull coating, class surveyor always looking.

- You need low reaction force and controlled hull pressure to meet design code.

Here the normal solution is:

Cone or cell rubber fender + large steel frontal panel + UHMWPE facing pads

Why?

- Rubber body absorbs energy.

- Panel spreads load so hull pressure stays within limit.

- UHMWPE pads give low friction so the ship slides smoothly along the berth as tugs work the line.

If you use rubber-only in this scene, you often see:

- Hot spots on hull.

- Paint ripping off.

- Complaints from shipping line and more downtime to patch fenders.

Scenario 3: Ro-Ro Ramp Or Ferry Berth With Sliding

On a Ro-Ro berth or ferry ramp, the ship:

- Comes in and out many times per day.

- Sits against the fender while ramp is operating.

- Slides up and down with tide and sometimes along the face.

For this duty you really want:

- Consistent friction (not too sticky, not crazy slippery).

- Very good wear resistance.

- Easy replacement when pad worn.

Again, rubber + panel + UHMWPE pads is the go-to combo. Ferry operators hate downtime; they want to just unbolt a pad, swap it, and keep schedule.

When To Combine UHMWPE Pads With Rubber Fenders

So, when do you mix both instead of choosing one?

You combine UHMWPE pads and rubber fenders when:

- Ship size is medium to large.

- Berthing energy is not small.

- Berth handle regular liner traffic, not just odd calls.

- Coating damage and claim risk hurt your profit.

- You think in life-cycle cost, not only first CAPEX.

Simple rules of thumb:

- Rubber-only for low-energy, small-craft berths, simple jobs.

- UHMWPE pads alone for guiding, sliding strips, pile protection where energy is low but wear is high.

- Combined system for most modern commercial ports and serious terminal projects.

This is also how many PIANC-style design guides and big EPC contractors think, even if they dont say it in marketing words.

How Dongxing Rubber Fits Into This Picture

Now we talk a bit business.

Dongxing Rubber is not just selling a few random plastic blocks. Your site sits as a High-Performance Engineering Plastic Products Manufacturer, focused on:

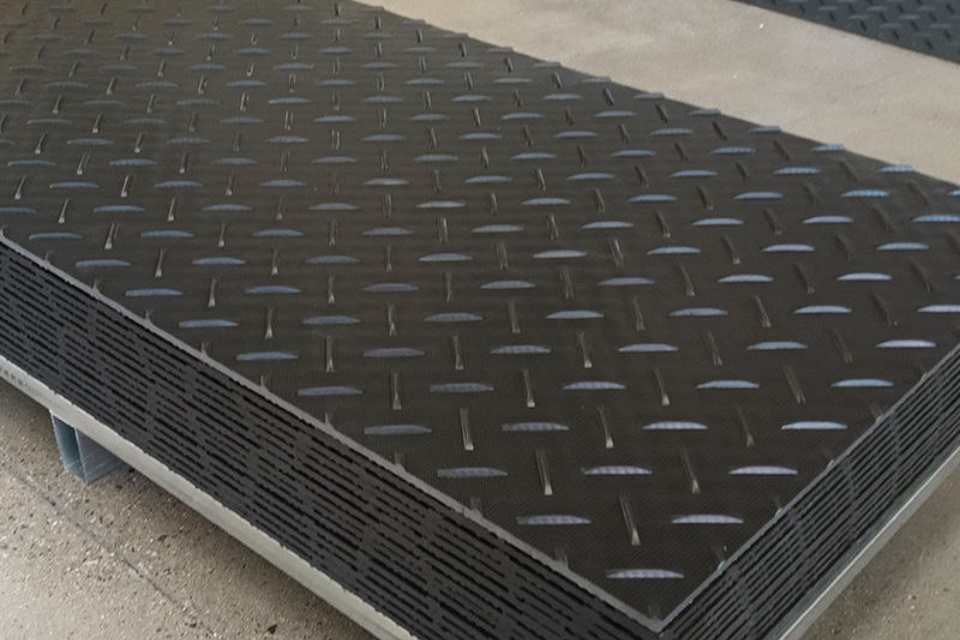

- UHMWPE & HDPE products: sheets, fender pads, outrigger pads, ground mats, ice rink boards. Here you can use customizable polyethylene UHMWPE sheets as raw material base.

- PP/PE products and nylon sheets.

- OEM / ODM custom machining and project support through your OEM/ODM services, drilling, bevelling, handle holes, ID marks.

- Bulk purchase for distributors and project contractors.

For the fender scene, this means:

- You can supply custom UHMWPE fender pads in the same material family as your UHMWPE HDPE sheets & plates.

- You can match pad dimensions to existing cone or cell fender panels.

- You can add chamfers, countersunk holes, radius corners, even color code for different berth lines.

- Lead time is short (samples in some days, production in some weeks, 24-hour response), which matters a lot when a jetty is down and port boss shout on the phone.

From the client view, combining rubber fenders on structure + UHMWPE pads from Dongxing Rubber gives:

- Better hull protection.

- Lower unplanned maintenance.

- Simple pad replacement instead of full fender swap.

Even if my spelling here is not perfect, the value is clear.

Closing Thoughts

You dont have to be a “fender guru” to make a smart choice:

- Rubber-only fenders: cheap, simple, good grip, fine for small boats and low-energy berths.

- UHMWPE fender pads: smooth sliding, low wear, protect hull coatings.

- Combination: rubber takes the hit, UHMWPE takes the slide, owner takes the long-term benefit.

When you design your next quay or upgrade an old jetty, ask one short question:

“Do I expect high traffic, big ships, or strict hull protection?”

If the answer is yes, then combining UHMWPE fender pads with rubber fenders is not luxury. It is just good, practical port engineering – and a clean business oppotunity for Dongxing Rubber and your clients.