-

Tian Dong Industrial Park, Decheng District Economic and Technological Development Zone, Dezhou City

Storage & Transport: Racks, Tethers, And Id Tags

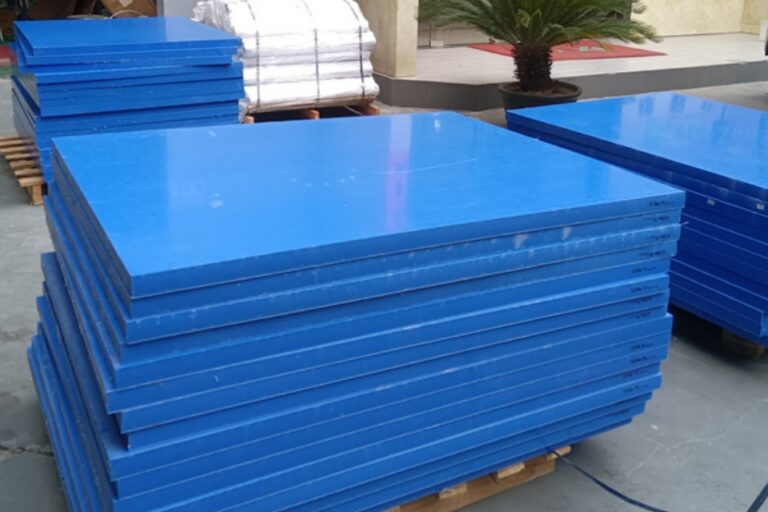

If you invest in good UHMWPE outrigger pads, but just throw them in the truck, you only finish half the job. Storage and transport decide if those pads stay flat, safe, and ready for the next lift. Bad storage slowly kills even the best plastic.

In this piece we talk about three very “boring” things that actually make or break your risk profile: racks, tethers, and ID tags. And we link them back to real crane work and to products like our UHMWPE HDPE sheets & plates and UHMWPE fender pads.

Table of Contents

Why Dedicated Pad Racks Beat Loose Stacking

You’ve probably seen this picture on site: pads lying under the toolbox, half buried under chains, some edges already chipped. Riggers is busy, so pads just “live” wherever there is space.

On paper the crane has nice UHMWPE pads.

In reality, you now have:

- bent corners,

- dirt and oil stuck on the surface,

- pads that maybe dont sit flat anymore.

Dedicated pad racks change that completely:

- They bolt to the truck bed, trailer, or crane chassis.

- Each rack holds a fixed number of pads, so the crew always knows where they belong.

- Lock pins or simple bars keep pads from jumping out when the truck brakes hard.

This sounds simple, but it cuts a lot of chaos. When pads have a real “parking place”, people put them back. When they slide around the deck, people kick them out of the way.

You can even line rack contact faces with UHMWPE plate cut from UHMWPE HDPE sheets & plates. That reduces metal-on-pad scuffing and keeps noise down when pads go in and out.

Steel Smart Racks For High-Volume Pad Storage

Small service trucks only carry 4–8 pads. Big crane fleets move dozens of pads between projects. That’s where steel “cage” racks make more sense than single pad holsters.

These smart racks:

- use heavy welded steel,

- stack multiple large pads upright,

- include forklift pockets and lifting lugs.

You treat your pads like one palletized unit, not 20 loose boards. For a rental yard or Dongxing Rubber–type OEM partner supporting many cranes, this is huge:

- Faster loading – the forklift grabs one rack, not pad by pad.

- Less damage – pads don’t fall over in the yard or bang around in the truck body.

- Cleaner yard layout – racks line up in rows; inventory is visible.

When you combine these racks with UHMWPE pads and even UHMWPE fender pads for marine jobs, you get a full “pad system” that travels cleanly between depots and sites.

Storage Is Part Of Safety: Keeping Pads “In Excellent Condition”

Safety rules often say something like: “Outrigger pads shall be in good or excellent condition and suitable for the load and ground.” Most people read that and think only about inspection.

But storage is step zero.

If you:

- leave pads in the sun on hot asphalt,

- store them under sharp steel parts,

- allow oil and chemicals to soak in,

you push your pad faster toward cracking, warping, or surface damage.

UHMWPE and HDPE are tough, low-friction materials, but they’re not magic. Good storage plus the right base material is what keeps:

- pad faces flat,

- edges intact,

- stress cracks away.

For example, using a simple rack plus a short roof section over the pad area on a truck can already cut UV exposure a lot. If you really want long service life, you pick a UV-stabilised grade from UHMWPE HDPE sheets & plates and also give it a decent parking spot.

So the argument is clear: storage practice is part of your safety case, not just a logistics choice.

Tethering Pads And Tools To Stop Dropped Objects

Now we move from “where it lives” to “what happens on the move”.

During lifting jobs, people carry pads up access stairs, onto platforms, into narrow streets. In crowded areas a dropped pad or tool can be a serious incident. A 30 kg UHMWPE pad sliding off a truck is no joke.

That’s where tethers and lanyards come into the picture:

- For smaller pads and cribbing, you can clip a short tether when you pass them up from ground to platform.

- For tools used around the pads (spirit levels, torque wrenches, shackles), tool lanyards keep them attached to the user or handrail.

- When you pull pads out of vertical racks at height, a short tether gives you a second chance if grip slips.

Is this overkill for some jobs? Maybe. But on high-rise, refinery, or plant turn-around work, clients already ask for dropped-object control in the lift plan. Showing that your pad handling includes tethers sends a clear signal: you take that requirement serious, not just on paper.

Why Every Pad Rack Needs Clear ID Tags

Let’s be honest: in many fleets nobody really knows the story of each pad.

- How old is it?

- For which crane class was it purchased?

- When was it last inspected?

Without ID tags, your pads turn into anonymous black squares. That’s a compliance risk.

ID tags fix this in a very simple way:

- Each pad or rack gets a unique ID code.

- The tag includes WLL / SWL or suited crane class, inspection date, and maybe owner name.

- Crew can log checks by ID in a simple app or spreadsheet.

For UHMWPE fender pads it’s similar. In ports and marine jobs, clients want traceability for each fender panel. A robust plate plus engraved or printed tag shows:

- which batch of UHMWPE fender pads you used,

- which OEM supplied it,

- what maintenance was done.

“No tag, no use” is a simple shop rule that keeps bad pads out of service without long debate at the crane.

Standardised Pad + Rack Kits Reduce Guesswork

One more step: you don’t just buy pads and racks randomly. You standardise kits.

A kit means:

- a defined pad size and thickness,

- the matching rack that fits exactly that size,

- the matching ID tag template,

- and sometimes even a standard tether set.

For Dongxing Rubber style customers (OEM/ODM and bulk buyers), this gives real business value:

- Faster quoting – sales teams offer “Kit A / Kit B” instead of customising every time.

- Simpler training – rigging crews learn one standard configuration per crane class.

- Less inventory mess – purchasing and maintenance track a small set of SKUs, not endless one-off parts.

From a materials angle, you pick a base from UHMWPE HDPE sheets & plates that matches your load and climate. Then you lock that into a kit bill of materials. No more mystery pads appearing on the truck.

Comparison Table: Storage And Transport Options

You can show the options to your project manager or HSE lead with a simple table like this:

| Option | Typical Design | Capacity / Example | Safety Impact | Best Use Case |

|---|---|---|---|---|

| Loose stacking on truck floor | Pads piled under chains, near toolbox | “Unlimited”, but messy | High risk of edge damage, trip hazard | Very small jobs, low maturity (not recommended) |

| Bolt-on pad racks | Steel or lined holders fixed to chassis | 2–8 pads per rack | Pads stay in place; easier inspection | Service trucks, city cranes |

| Steel cage / smart racks | Welded steel frame with forklift pockets | Up to dozens of large pads | Safer yard handling, less manual lift | Rental fleets, large crawler cranes |

| Tethered handling | Short lanyards on pads or tools | 1 pad / tool per tether | Cuts dropped-object incidents | High-rise, plant, refinery, crowded streets |

| ID-tagged pads and racks | Metal / plastic tags fixed on pad or rack | One tag per asset | Full traceability and clear status | Any fleet under strict audit or LOLER-type rules |

You dont need perfect English in the table to make the point. What matters is that your team sees: storage and transport is a design choice, not an afterthought.

Closing Thoughts

Racks, tethers, and ID tags look “small” next to a massive crane. But they decide if your UHMWPE pads work like the datasheet promises or slowly turn into scrap.

If you:

- choose the right rack concept for your fleet size,

- treat tethering as part of your lift plan,

- and make ID tags the entry ticket for any pad to go on a job,

you protect people, protect equipment, and stretch pad service life.

From our side as a high-performance engineering plastic supplier, we see one more thing: when customers design storage and transport together with the pad material, the whole system performs better. That’s true for outrigger pads on land and for UHMWPE fender pads facing ships and waves.

You already pay for good plastic. Let’s not lose that value on the truck ride.