-

Tian Dong Industrial Park, Decheng District Economic and Technological Development Zone, Dezhou City

Inspection Checklists For Crane Pads: Cracks, Creep, And Wear

You trust your crane.

But the crane is only as safe as the pads under its feet.

A lot of accidents dont start with a boom failure. They start with a tired outrigger pad that nobody really looked at. In this post we walk through real inspection checklists for crane pads, with focus on cracks, creep, and wear.

We also link the ideas back to UHMWPE / HDPE sheets & plates, and the kind of manufacturing we do at Dongxing Rubber for custom pads and lead-boron polyethylene plates.

Table of Contents

Why Crane Pad Inspection Checklists Matter On Every Job

You already know the basic rules: firm ground, correct pad size, full contact.

But in the field things get messy:

- Rush jobs

- Soft ground “that should be fine”

- Old pads that “always worked before”

When you dont have a written crane pad inspection checklist, you rely on memory and mood. That is when people miss:

- Fine cracks in the pad

- Slow creep (permanent deformation)

- Polished, slippery surfaces

- Broken or loose handles

A simple checklist gives your operators a repeatable routine. It also protects your company when you work with rental cranes, owners, or third-party inspectors.

Crane Pad Inspection Checklist: Cracks You Can’t Ignore

Visual inspection for cracks and edge damage

Start with a slow walk-around. No fancy tools. Just eyes and hands.

Check every pad for:

- Through cracks from the top surface to the bottom

- Long splits running from the edge into the pad

- Broken corners or big chunks missing

- Layer separation if the pad is laminated or stacked

If you see a crack that reaches deep into the pad, treat it like a cracked hook. This pad is done for crane duty. Maybe you can re-use it for light blocking, but not under outriggers.

When to retire a cracked outrigger pad

Here is a simple rule that crews remember:

- Hairline surface lines that don’t grow = monitor

- Deep or growing cracks = remove from service

- Any damage that reaches the outrigger footprint area = scrap

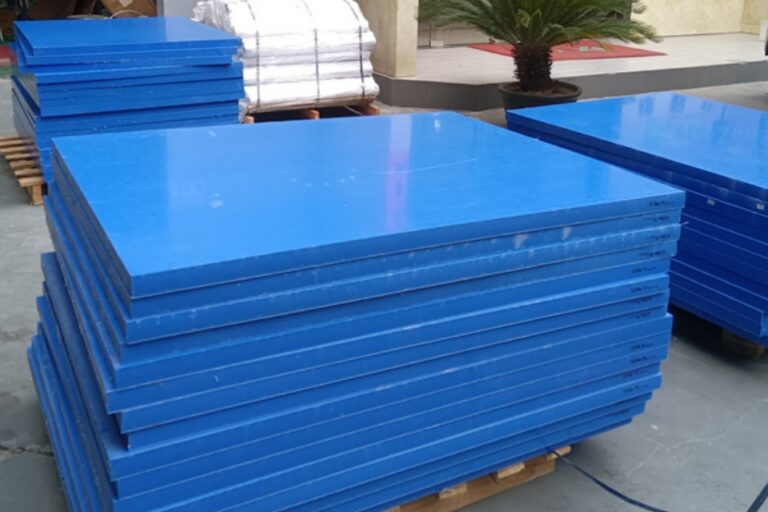

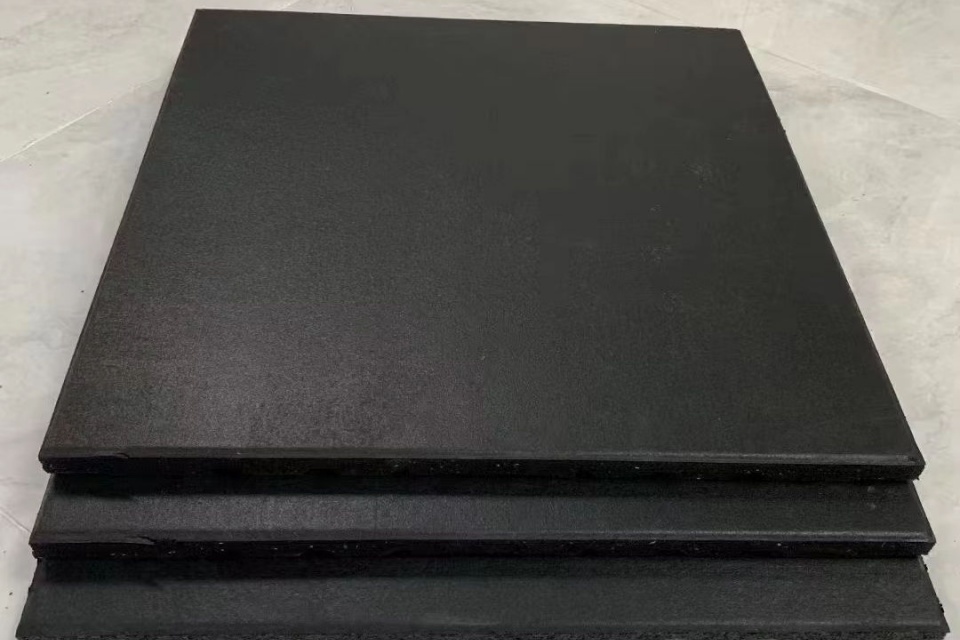

For UHMWPE and HDPE crane pads made from high-performance engineering plastic sheets, cracks often come from overload, sharp edges on steel feet, or impact during transport. A good checklist forces you to ask:

- Was the pad undersized for this crane or soil?

- Do we need different pad geometry next time?

This is also where Dongxing Rubber adds value. When we see repeated crack patterns from customers, we redesign pad shapes, fillets, and thickness using our UHMWPE HDPE sheets & plates production know-how.

UHMWPE Creep: Slow Deformation That Bites Later

How creep shows up on site

Creep is a slow, permanent deformation under load. With UHMWPE pads you dont see it like a dramatic break. You see it as:

- Pad that used to be flat now has a dish in the center

- Corners lift off the ground when the outrigger sits in the middle

- Deep, permanent footprint marks that stay even after you remove the crane

- Pads that no longer stack flat on the truck

Creep gets worse when:

- Loads are high for a long time

- Ground is soft and not well spread

- Temperature is high (hot weather or hot surfaces)

If your checklist only looks for cracks, you miss this slow shape change.

Linking pad sizing, soil condition, and UHMWPE HDPE sheets & plates

When we design pads from UHMWPE HDPE sheets & plates, we talk about:

- Contact area vs. expected ground bearing

- Safety margin for soft spots

- Thickness vs. creep under long-term load

On site, your checklist can include simple questions:

- Does the pad stay flat when loaded?

- Do we see corner lift or rocking?

- Has the pad shape changed compared with new stock pads?

If yes, the pad might still “work” today. But it is sending you a warning. Many fleet managers keep one reference pad in each yard to compare shape against the older pads.

Wear, Surface Texture, And Contamination

Slippery pads and side-load risk

Even if the pad has no cracks and no big creep, surface wear can kill friction. That is dangerous when you:

- Slew over the side

- Work with wind loads

- Work on a slight slope

Things to look for:

- Shiny, polished areas where texture is gone

- Deep grooves from repeated use of the same outrigger foot

- Local “steps” or ridges that focus stress

When the anti-slip texture is gone, the pad behaves like a plastic ice rink panel. The crane can “walk” under side load. Not fun.

Cleaning and re-surface routines in real jobsites

Your checklist should also ask:

- Is there mud, gravel, or ice stuck under the pad?

- Is there oil or grease on the top face?

- Can we clean it now with the tools on site?

A lot of crane guys just kick the pad and call it good. That’s not enough. Make “clean pad, clean ground” a line on the form. Simple, but it works.

At factory level we use the same mindset when we produce ice rink products and lead-boron polyethylene plates for shielding. Surface quality is not decoration. It changes how the product behaves under load or radiation. The same thinking goes back into our crane outrigger pads.

Sample Crane Pad Inspection Checklist Table

You can drop this table into your own SOP, toolbox talk, or crane handbook.

| Item | What to Check | Typical Problem (Cracks, Creep, Wear) | Action on Site |

|-------------------------------|------------------------------------------|---------------------------------------------------|----------------------------------------|

| Pad ID & rating | Marking, WLL, size, thickness | Marking gone, rating unknown | Verify with office; tag or scrap |

| Surfaces & edges | Top, bottom, all sides | Deep cracks, long splits, broken corners | Remove from crane service |

| Creep / shape change | Flatness under and after load | Dish shape, corner lift, permanent footprint | Review pad sizing; plan replacement |

| Surface texture | Anti-slip pattern, local grooves | Polished areas, deep tracks from outrigger foot | Increase monitoring; replace if severe|

| Contamination | Dirt, mud, oil, gravel, ice | Slippery film, stones under pad, packed mud | Clean, re-seat pad, recheck stability |

| Handles & lifting points | Rope, steel bars, bolts, holes | Cracked handles, loose bolts, sharp burrs | Repair or remove pad from use |

| Ground contact & stability | Contact with soil or timber cribbing | Rocking, partial contact, visible sinking | Rebuild support, maybe larger pads |

| Record & sign-off | Who inspected, date, crane / job name | No record, no name, no trace | No lift until checklist is completed |

You can tweak the wording to match your company style or local standards.

Many customers ask us to print QR codes or pad IDs into the UHMWPE pad itself. That makes it very easy to track inspections in digital systems.

Turning Checklists Into Value For Your Crane Fleet

A good inspection checklist is not just “paper for safety guys”. Done right, it gives you:

- Fewer pad failures and fewer “panic re-rigging” moments

- Better use of your pad stock (you retire bad pads on time, not too early, not too late)

Because Dongxing Rubber controls the full chain for UHMWPE & HDPE manufacturer products, we can match your checklist with the right hardware:

- Custom ground protection & road mats for soft sites

- UHMWPE outrigger pads built from MG engineering plastic sheets and PP/PE products

- Options for OEM/ODM services, logo engraving, color coding by capacity

- Batch orders for rental fleets and big contractors

- Samples in short lead time, then bulk production with stable quality

If you already run cranes but your pads look tired, send us your real-world photos and rough job scenarios. We help you turn what you see in the field—cracks, creep, and wear—into better pad design and a simple inspection checklist that your operators actually use.

Look under the crane. The checklist starts at the pad.