-

Tian Dong Industrial Park, Decheng District Economic and Technological Development Zone, Dezhou City

Temperature, Chemicals, And UV: Extending Pad Service Life

When your crane or truck goes on site, the outrigger pads and ground mats sit in the worst place: right between steel and dirt.

They see hot sun, oil leaks, winter cold, and some pretty rough handling.

If you treat pads like disposable wood blocks, they die fast.

If you match material + environment + simple care, they work many many years and save a lot headache.

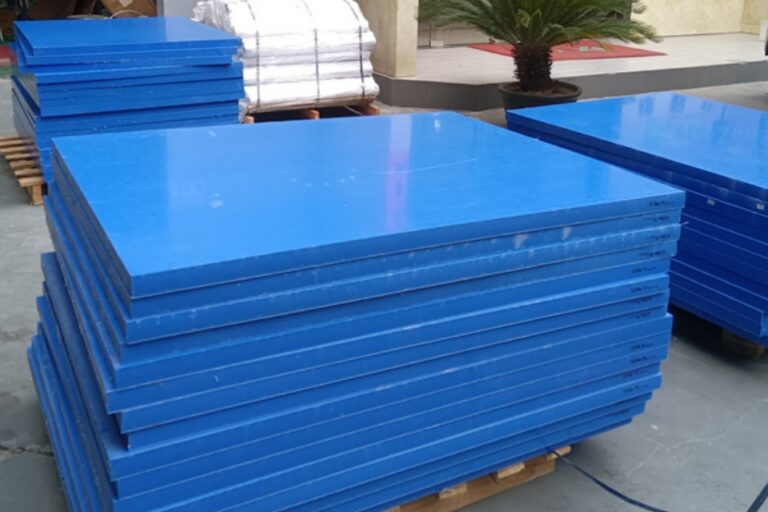

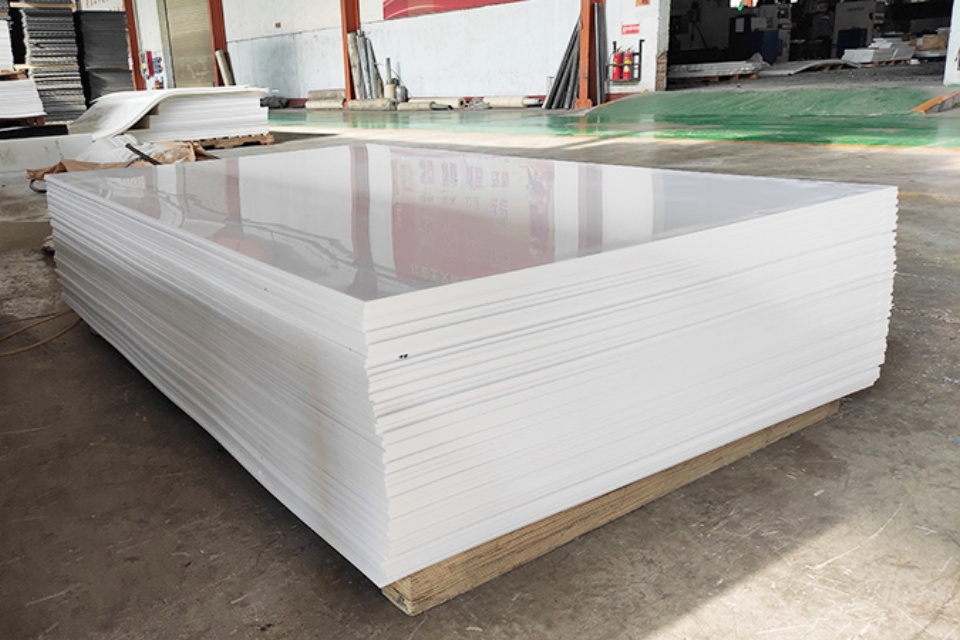

In this article we talk about temperature, chemicals, and UV for UHMWPE / HDPE outrigger pads and ground protection mats, and how to get longer service life from products like your UHMWPE HDPE sheets & plates and HDPE sheets.

Table of Contents

Temperature Effects On UHMWPE And HDPE Outrigger Pads

Temperature is the first big killer.

Same pad, same crane, but summer on blacktop and winter on frozen soil is totally different story.

High Temperature Creep And Pad Deformation

On very hot days:

- Surface of black road can reach very high temperature.

- UHMWPE and HDPE become softer when it’s hot.

- Under high point load from the outrigger foot, the pad may creep more.

If the pad is too thin or the working load is close to the limit, you may see:

- Visible “dish” shape in the center.

- Edges lifting a bit.

- Pad becomes harder to stack flat later.

To avoid this:

- Use proper thickness and safety margin in the design.

- Check the material’s working temperature range when you choose UHMWPE HDPE sheets & plates.

- On very hot asphalt, add a small timber or steel distribution layer if needed, so the pad doesn’t sink in soft asphalt like pizza in oven.

Low Temperature Impact And Brittle Cracks

In winter conditions:

- Many plastics get stiffer and more brittle.

- A hard impact on the corner (for example, dropping the pad from the truck) can start a crack.

- Freeze–thaw cycles around small notches will grow that crack slowly.

Good UHMWPE and HDPE grades still work fine at low temperature, but you should:

- Avoid hammer hits on pad corners.

- Don’t slam the outrigger shoe directly on the edge.

- Check pads for white stress lines or small cracks before big lifts.

A little daily inspection is cheaper than a surprise pad failure in the middle of a pick.

Chemical Resistance Of UHMWPE HDPE Sheets & Plates

Real job sites are not clean labs.

You have hydraulic oil, diesel, grease, concrete slurry, road salt, cleaning chemicals and sometimes even acid rain.

UHMWPE and HDPE have excellent chemical resistance, this is why so many outrigger pads and ground mats use these resins. But “excellent” doesn’t mean “invincible”.

Typical Chemical Exposure On Job Sites

Common situations:

- Hydraulic hose bursts → oil pool under the pad.

- Mixer truck washes chute → concrete water runs around the mat.

- Winter highway job → de-icing salt everywhere.

- Workshop cleaning → solvent sprayed near stored pads.

If pads were made from wood, they soak all this stuff and rot.

With UHMWPE / HDPE, the pad doesn’t suck water, but long-term contact with strong chemicals can still:

- Roughen the surface.

- Change friction a bit.

- Leave ugly stains that make pads look “old” (even if still structurally OK).

Simple Chemical Control Rules

You don’t need rocket science:

- Wipe oil and fuel from pads after the lift.

- Don’t leave pads sitting in thick concrete slurry for weeks.

- Avoid aggressive solvent cleaners; use mild detergent + water.

- In salty regions, spray pads with water before long storage, just like you’d do with truck chassis.

For big fleets and rental yards, these small habits plus good UHMWPE HDPE sheets & plates selection is the difference between “replace every few seasons” and “pads still fine after many years”.

UV Exposure And Outdoor Pad Aging

UV is the slow, quiet enemy.

Pads look okay for a while, then one day you see:

- Faded color.

- Chalky surface.

- Little cracks on corners.

That’s UV ageing + oxygen + time.

Why UV Stabilized HDPE Sheets Matter

Standard plastics can degrade under long sun exposure.

To fight that, serious manufacturers:

- Use UV-stabilized UHMWPE / HDPE grades.

- Add carbon black or other pigments to block UV.

- Choose resins tested in outdoor weathering.

When you buy HDPE sheets for pad production or custom profiles, ask for:

- UV-stabilized grade.

- Outdoor service life expectation.

- Color option (dark colors usually handle UV better).

If your customer’s pads live on open yard 365 days, not in warehouse, this detail really matter.

Storage Habits To Cut UV Damage

Even good material gets old faster if you abuse it.

Easy tricks:

- Store pads under a roof or inside container when not in use.

- If you must leave them outside, stack them so only the top piece takes full sun.

- Avoid leaving thin pads on the roof of containers or cabins for months just because “no space”.

These things sounds small, but across a big Dongxing Rubber style fleet, they cut replacement rate a lot.

Combining Temperature, Chemicals, And UV In Real Job Sites

In real life, these factors don’t come one by one. They come together.

Imagine this scene:

- Summer highway job.

- Temperature on asphalt is very high.

- Pads sit under outriggers all day in direct sun.

- A hose leaks hydraulic oil.

- At night, heavy rain cools everything fast.

Here you have:

- High heat → more creep.

- UV → faster surface ageing.

- Oil → dirt sticking and harder cleaning.

- Thermal shock after rain.

If the pad is cheap material, thin design, and crew drags it over gravel, service life goes down fast.

With high-performance UHMWPE HDPE sheets, proper thickness, and basic care rules, the same job becomes no big problem. You don’t even think about the pads, they just work. That’s the kind of “invisible stability” your customer want (even if they not say it).

Material Selection And Maintenance Strategy For Longer Service Life

From manufacturer view, pad life is not only “how strong the plastic is”.

It’s a system problem:

- Material (UHMWPE, HDPE, blend, filler).

- Design (thickness, size, chamfer, handle).

- Working condition (climate, ground, crane class).

- Operator habit.

Here Dongxing Rubber–style service comes in:

- For heavy cranes and rough sites: recommend thicker UHMWPE pads made from UHMWPE HDPE sheets & plates with UV stabilizer, maybe custom color for their brand.

- For rental companies: focus on low water absorption, chemical resistance, easy cleaning and how this reduce downtime and complaints.

- For long-term projects: propose a simple inspection checklist (check cracks, warping, handles) and yearly replacement plan for high-risk pieces.

you don’t just sell one pad, you co-design the pad package, do OEM/ODM services, and help them build a stable lifting “toolbox” for many sites. Even customer English is not perfect, they can still feel you really understand the jobsite pain.

Example Comparison Table For Pad Service Life

You can use or adjust this table directly in your blog.

| Exposure factor | Main risk | Typical situation on site | Design choice (UHMWPE/HDPE) | Simple crew action |

|---|---|---|---|---|

| High temperature | Creep, warping | Crane on black asphalt in summer | Use thicker pads, proper safety factor, UV-stabilized HDPE sheets | Don’t park pads next to exhaust, avoid soft fresh asphalt when possible |

| Low temperature | Brittle crack, edge damage | Winter lifting, frozen ground | Choose grades with good low-temp impact strength | Don’t drop pads from truck, avoid hammer hitting corners |

| Chemicals | Surface attack, ugly stains | Oil leaks, concrete water, salt | Use UHMWPE / HDPE with strong chemical resistance | Wipe oil, rinse salt and slurry before long storage |

| UV | Fading, chalking, small cracks | Long-term outdoor storage | Select UV-stabilized UHMWPE HDPE sheets & plates | Store under cover, stack pads so fewer faces see full sun |

| Mechanical abuse | Deep gouges, notch cracks | Dragging over gravel, steel edge impacts | Add chamfered edges, handles, anti-slip pattern | Train crew: lift not drag, keep pad fully under outrigger shoe |

This kind of table makes the logic clear for engineers, project managers, and buyers. They see that long pad life is 50% material, 50% behavior.

Wrap Up: Turning Pads Into Long-Term Assets

If you pick good UHMWPE / HDPE material, match it to your temperature, chemical, and UV environment, and teach crew two or three simple habits, pads stop being “consumable blocks”.

They become long-term assets that stay in your fleet for many projects.

For customers who buy from a manufacturer like Dongxing Rubber with custom machining, OEM/ODM service, bulk order support, fast samples and quick response, it’s not only safer. It also means:

- Less emergency replacement.

- Cleaner site image.

- Easier HSE communication with end users.