-

Tian Dong Industrial Park, Decheng District Economic and Technological Development Zone, Dezhou City

Round Vs Square Pads: Stability Trade-Offs

You stand next to a crane, mud up to your ankles, operator staring at you and asking:

“Round pads or square pads today?”

If you only say “round is safer” or “square is stronger”, you miss the real story.

Let’s walk through what actually drives stability, in simple words, and how you choose the right UHMWPE crane outrigger pads for your fleet, especially when you use Dongxing Rubber as your partner.

Table of Contents

Key Stability Factors for Crane Outrigger Pads

Contact Area and Ground Bearing Pressure

For stability, the main question isn’t “round or square”.

The first question is: how big is the contact area?

- Bigger area → lower pressure on the soil

- Lower pressure → less sink and tilt

- Less sink → more stable boom and jib

In practice, you look at ground bearing pressure:

Ground pressure ≈ load on the pad ÷ pad contact area

If your pad area is too small, both round and square pads will punch into soft soil.

So shape is the second step, not the first.

Pad Stiffness and Material Selection

The pad also needs enough stiffness so it doesn’t bend like a thin plate.

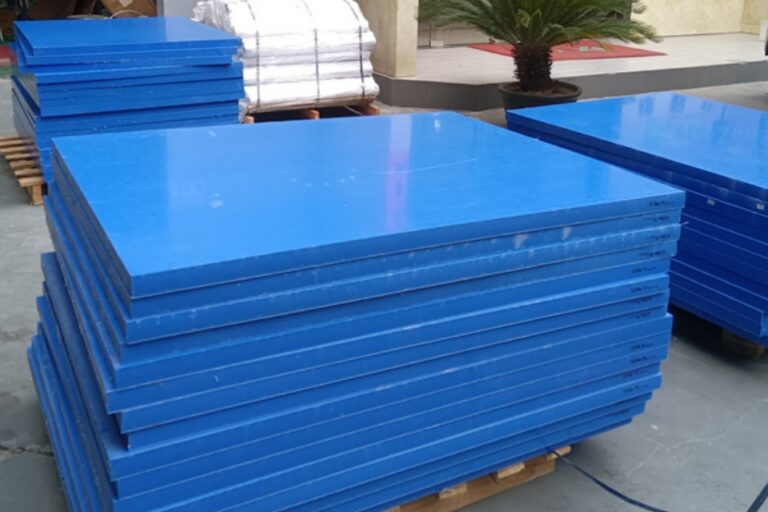

- UHMWPE and HDPE sheets and plates have high impact strength and good stiffness for pads.

- If you use low-grade wood or thin steel, you can get local bending and edge curl.

- With good engineered UHMWPE plate sheet, you spread load more evenly into the ground.

This is why many fleets move from plywood to engineered UHMWPE outrigger pads from suppliers like Dongxing Rubber.

You get predictable performance, not “hope this plank survive today”.

Geometric Differences Between Round and Square Pads

Now we talk shape.

Let’s compare round and square pads with the same outer size.

Area Comparison at the Same Outer Size

Imagine two pads:

- Square pad: 600 mm × 600 mm

- Round pad: diameter 600 mm

We can compare their contact area like this:

| Pad shape (same outer size) | Example size | Approx. contact area | Relative area vs square |

|---|---|---|---|

| Square outrigger pad | 600 × 600 mm | 0.36 m² | 100% |

| Round outrigger pad | Ø 600 mm | ~0.283 m² | ~78.5% |

So, with the same outer size, the round pad has less area.

That means higher ground pressure and more chance of sink on weak soil.

To reach the same area, a round pad needs a bigger diameter than the side length of a square pad. When you have limited truck width or toolbox space, this matters a lot.

Soft Ground Stability and Edge Effects

Load Distribution on Soft Soil

On hard concrete, the difference between shapes is small.

On soft soil, you see the effect much more fast.

- A square pad has corners.

On very soft ground, these corners can dig in deeper, like four tiny “feet”. - A round pad has no corners.

The edge is continuous, so the load around the edge is more even.

So on poor soil:

- Corners on square pads sometimes become local “stress points”.

- Round pads often give a bit more uniform load distribution and can reduce “corner punching”.

This doesn’t make round pads magic.

If the area is too small or soil bearing capacity is too low, both shapes will still sink.

But when you already size the pad correctly, shape can fine-tune how stress spreads in the ground.

Handling, Transport, and Site Efficiency

Shape also changes how your crew handles the pads every single day.

Manual Handling and Ergonomics

Big pads are heavy, even if you use UHMWPE.

People still need to drag, lift, or roll them, and this is where round pads often win.

- Round pads

- You can stand them on edge and roll them like a wheel.

- One person can move a large diameter crane outrigger pad more easy across a yard or jobsite.

- You reduce back strain and awkward lifts.

- Square pads

- You can’t really roll them; they “thump” on each corner.

- Large sizes may need two people or a small crane hook for safe moving.

If you run a rental fleet or high-volume lifting operation, small ergonomic gains add up.

Less time moving pads = more time actually lifting.

Stacking and Storage Efficiency

Inside a truck body or container, geometry also matters:

- Square outrigger pads stack like tiles.

They fill rectangular spaces with almost zero wasted gap. - Round pads stack in neat piles, but in a rectangular box they leave dead corners.

So if your transport space is tight and you want maximum contact area per cubic meter of storage, square pads have an advantage.

Soft Ground Case: Round vs Square in a Real Scenario

Let’s imagine a typical scenario.

- Truck crane working on a reclaimed yard with mixed fill.

- Some spots are harder, some spots are still a bit soft and wet.

- You choose UHMWPE crane outrigger pads instead of timber, because you know the ground is tricky.

What Happens With Square Pads?

- You place a square pad under the outrigger.

- One corner happens to sit near a softer patch.

- As you lift, that corner sinks faster, pad tilts a few degrees.

- Outrigger foot now sits on a slightly sloped surface.

- Crane has to work with a small extra side-load, not ideal.

What Happens With Round Pads?

- With the same load but a well-sized round pad, the edge is continuous.

- There is no sharp corner to dig in; load “flows” around the rim.

- The pad still may settle, but more evenly.

- The outrigger plate tends to stay more parallel to the ground.

Again, this doesn’t replace correct ground assessment or matting.

You still may need ground protection road mats under the pads to bridge very weak zones.

But it’s one more tool in the engineer toolbox when you design a safe lifting plan.

How to Choose Round or Square Pads for Your Fleet

You don’t need a PhD to make a good decision.

You just need a simple checklist.

Key Questions to Ask

- What ground do we see most?

- Mostly concrete and hard asphalt → shape is less critical.

- Lots of fill, clay, grass, construction backfill → soft ground logic becomes important.

- How limited is our storage and transport space?

- Tight truck body, small toolbox → square pads give more area for the same footprint.

- Space not a big issue → you can oversize round pads and still store them fine.

- How often do we move pads by hand?

- Many small setup changes per day → round pads reduce fatigue because you can roll them.

- Mostly crane-assisted pad handling → shape matters less for ergonomics.

- Do we already use UHMWPE / HDPE sheets in other gear?

- If yes, you can align your material strategy:

UHMWPE & HDPE sheets and plates for custom cribbing blocks,

and standard crane outrigger pads in round or square shapes.

- If yes, you can align your material strategy:

Some fleets also add heavy duty UHMWPE cribbing blocks under the pads to fine-tune height and spread load even more.

Example Selection Table for Crane Outrigger Pads

Here’s a simple decision helper you can reuse in your own spec sheet.

| Scenario | Ground type | Handling priority | Storage limit | Suggested pad shape | Material tip |

|---|---|---|---|---|---|

| Urban crane rental, short lifts | Mostly concrete | Medium | High | Square pads | UHMWPE square pads plus compact cribbing blocks for toolbox-friendly stacks |

| Bridge work over soft fill | Soft / mixed | Medium | Medium | Round or large square | UHMWPE pads with extra area, thicker section, plus optional cribbing blocks |

| Wind farm, many daily moves | Mixed terrain | Very high | Medium | Round pads | Round UHMWPE pads that crew can roll easily between positions |

| Heavy lifting contractor with pad truck | Mixed | Low (crane moves) | Low | Either, area first | Focus on correct area; shape is second step, use UHMWPE or HDPE core sheets |

Why Dongxing Rubber Pushes Area First, Shape Second

From the view of a high-performance engineering plastic manufacturer, the logic is clear:

- Start with required area and stiffness for safe ground bearing.

- Choose UHMWPE or HDPE grade that handles your load, climate, and chemical exposure.

- Then tune shape (round or square) for how your people actually work:

- round for easy rolling and soft ground behaviour,

- square for maximum area density and tight storage.

That’s how Dongxing Rubber designs its crane outrigger pads and stability mats:

you get both round and square options, but all built from proper UHMWPE plates, not random timber offcuts.

If you keep this order in mind — area, material, then shape — you’ll pick pads that don’t just look nice on a spec sheet, but actually keep your crane standing where it should: straight, stable, and boringly safe.