-

Tian Dong Industrial Park, Decheng District Economic and Technological Development Zone, Dezhou City

Outrigger Pad Sizing: Calculating Foot Pressure And Pad Area

When you put a crane or truck on soft ground, you don’t really park a machine.

You park tons of force into the soil.

If the outrigger pad is too small, the leg “punches” the ground, you get sinking, tilt, cracked concrete, and sometimes very bad stories on the jobsite. If the pad is sized right, everyone just work and goes home.

In this article we walk through, in plain language:

- how to think about outrigger load,

- how to deal with ground bearing capacity,

- how to use a simple foot pressure formula to get pad area,

- and why nylon sheets and UHMWPE pads from Dongxing Rubber make sense as the last layer between steel and soil.

Table of Contents

Outrigger load calculation

First thing: don’t divide crane total weight by four and call it a day.

Real life is more messy.

- One side can carry more when you boom over that side.

- Long radius picks push more reaction into the “heavier” outrigger.

- Wind, slewing, dynamic effects add extra peak loads.

On a real project, the rigging supervisor should:

- read the load chart and outrigger reaction table from the crane maker,

- pick the worst-case configuration (max radius, heavy pick, one side loaded),

- take the max single outrigger reaction as the design value.

If you don’t have nice tables, you use conservative engineering, or you call someone who does this every day. Guessing “ah, it’s about equal on each leg” is how people end up re-levelling crib stacks at 2 a.m.

Ground bearing capacity and soil conditions

Next question: how strong is the ground under your pad stack?

You can’t see bearing capacity with your eyes. Clay can look “ok” and still be very weak. A geotech report is best, but many sites don’t have it ready. So people use typical ground bearing capacity values with safety margin.

Here’s a simple reference table you can use in early planning (numbers are indicative only, not design code):

| Soil or base type | Typical allowable bearing pressure (kPa) | Comment |

|---|---|---|

| Very soft clay / fill | 50–75 | High risk, needs big pads |

| Firm clay | 100–150 | Many normal jobsites |

| Medium dense sand | 150–200 | Better, still watch for water |

| Dense sand / gravel base | 250–300 | Good for heavy outrigger loads |

| Reinforced concrete slab | 300+ (if designed for it) | Check slab design, not just guess |

You see the problem quickly:

same outrigger load, totally different required pad area when you move from dense gravel to soft fill.

On many sites supervisors just say “ah, it’s firm enough”. That’s not a soil report. When in doubt, you treat the ground as weaker, and you upsize the pad. Cheap insurance.

Foot pressure formula and pad area calculation

Let’s keep the math as human as possible.

The basic idea is simple:

Ground pressure = Load on outrigger ÷ Pad area

We want ground pressure ≤ allowable bearing capacity.

So we turn the formula around to solve for required pad area:

Required pad area = Load on outrigger ÷ Allowable ground pressure

That’s it. No rocket science.

But you must feed the formula with realistic numbers, not wishful thinking.

- Use the maximum outrigger reaction from the crane data.

- Use a conservative bearing capacity based on soil type or report.

- Add an internal safety factor inside your head: if the math gives 1.0 m², you don’t order a 1.0 m² pad and feel clever, you go a bit bigger.

From pad area to pad size

Area is not what you buy. You buy length x width.

If the calculation says you need 1.2 m², and you want a square pad, you do:

- Side length ≈ √1.2 ≈ 1.1 m

So a 1.1 m × 1.1 m pad will roughly hit the target (or you pick 1.2 × 1.2 m and sleep better).

For rectangular pads, same concept:

- You choose any L × W that gives area ≥ required area.

- Maybe 1.0 m × 1.3 m, if that fits your truck better.

One more detail people forget: the real contact area is sometimes smaller than the pad area, because the outrigger shoe might not spread the load perfectly. So for safety you don’t design at the limit.

Pad material strength and deflection

So far we only looked at soil. But the pad itself can fail:

- too much compressive stress and the pad can crack or creep,

- too much deflection and the crane goes out of level.

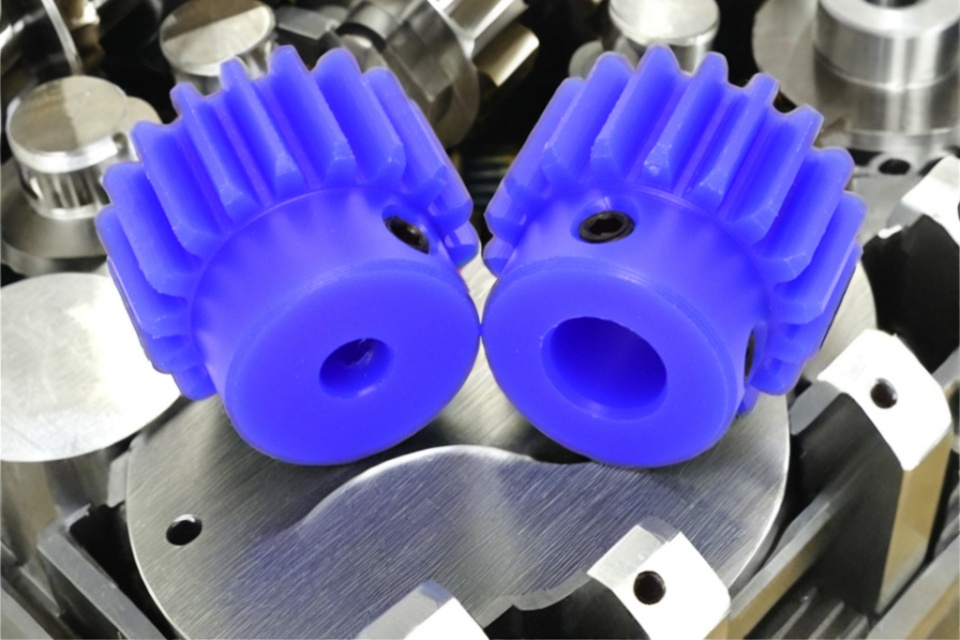

That’s why heavy-duty pads usually use engineering plastics like:

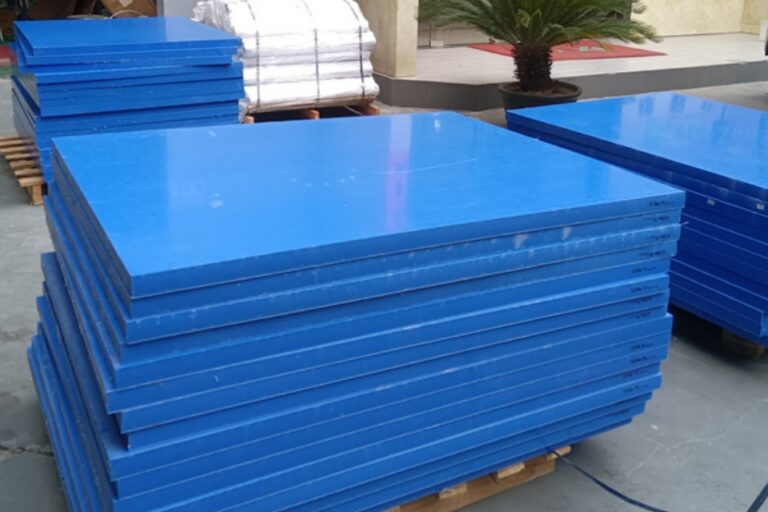

- UHMWPE (ultra-high-molecular-weight PE)

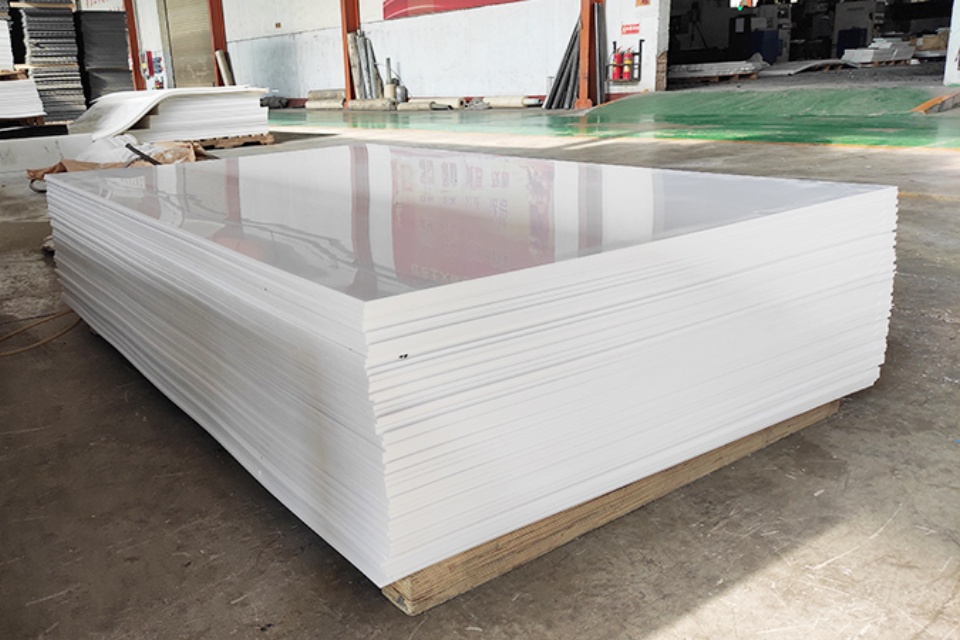

- Nylon sheets (PA6, PA66) in some projects

- sometimes stacked with timber cribbing underneath

These materials give:

- high compressive strength,

- good impact tolerance,

- no rust, low water absorption (especially UHMWPE / HDPE),

- lighter weight than steel for the same size.

At Dongxing Rubber we look at both sides of the problem:

- What does the ground need? (pad area)

- What does the pad material need? (thickness, grade, safety margin)

If you push nylon or UHMWPE far above its compressive limit, it may not explode, but it will creep slowly, and your nice level bubble starts walking away from center.

Practical sizing example for crane outriggers

Let’s walk a simple example idea. Numbers are just for understanding, not for you to copy straight into a lift plan.

Imagine:

- A truck crane on firm clay ground.

- Max outrigger reaction from the load chart: “big number” kN.

- Ground bearing capacity from the engineer: “moderate” kPa.

You:

- Plug the outrigger load and bearing capacity into the formula.

- Get a required area, say it comes out around 1.5 m² per outrigger.

- Choose a pad size, maybe 1.3 m × 1.3 m outrigger pads UHMWPE pad, stacked on timber if needed.

- Check material rating: Dongxing Rubber will suggest suitable thickness and grade so pad stress stays under limit.

In practice you also look at:

- Pad stack height (too tall = unstable crib),

- how the pads fit on the truck,

- how often you move the crane (weight matters to the crew),

- and any client rules, like “no plastic directly on old slab, use timber underlayer”.

The key point: you make decisions based on numbers and soil, not just “we always use this size”. That habit fails the moment you land on softer ground or heavier pick.

Why nylon sheets and UHMWPE pads fit heavy equipment projects

Now, where do nylon sheets come in, besides being another plastic buzzword?

Nylon has:

- high compressive strength,

- good stiffness,

- decent wear resistance.

UHMWPE has:

- very low friction,

- great impact resistance,

- very good performance in cold climates,

- excellent toughness even with repeated loading.

For many customers, the smart combo is:

- use UHMWPE or HDPE pads as the main crane outrigger pads,

- use machined nylon sheets where you need stiffer inserts, spacers, or custom interfaces between steel shoe and plastic pad,

- design the whole stack so load spreads gradually from outrigger foot → nylon/UHMWPE pad → timber crib → soil.

If you’re speccing parts for your fleet or reselling to contractors, you can take raw nylon sheets from Dongxing Rubber and machine:

- custom pad spacers,

- wear plates,

- bolt-on blocks that key the outrigger shoe so it doesn’t slide.

This gives you a full system, not only “one flat board under the leg and pray”.

Working with Dongxing Rubber for custom outrigger pads

Most end customers don’t have time to run all formulas for each project. They just know:

- “My crane is about this big.”

- “Soil is kind of soft, kind of ugly.”

- “Client doesn’t want broken paving and claims.”

That’s where we step in.

Dongxing Rubber focuses on high-performance engineering plastic products and OEM/ODM work:

- UHMWPE / HDPE pads and ground mats,

- nylon sheet machining,

- batch orders for rental fleets and distributors,

- custom sizes for different outrigger shoes and support frames.

You share:

- crane models,

- typical rigging scenarios,

- rough soil conditions and safety policy.

We help you turn it into a pad package that fits your line: correct area, thickness, material, and an eye on logistics (how crews carry and store the pads so they actually use them).

It’s not about magic or fancy slogans.

It’s about getting the foot pressure under control, so your crane, your ground, and your client’s pavement all survive the job.