-

Tian Dong Industrial Park, Decheng District Economic and Technological Development Zone, Dezhou City

Installation Pitfalls: Gaps, Penetrations, And “Streaming” Paths

When you design shielding with UHMWPE, HDPE or borated PE, the drawing always looks nice. Smooth walls, clean corners, no holes.

But the real problem is not the drawing. It’s the installation details: tiny gaps, pipe holes, door clearances, and all those “streaming” paths that sneak through your nice design.

If you ignore them, even high-performance shielding blocks or ice synthetic panels will not save you. The dose sneaks out along the easiest way, like water finding a crack.

Table of Contents

Radiation Streaming In Modular Shielding Systems

In modular shielding, you usually stack:

- Borated polyethylene blocks

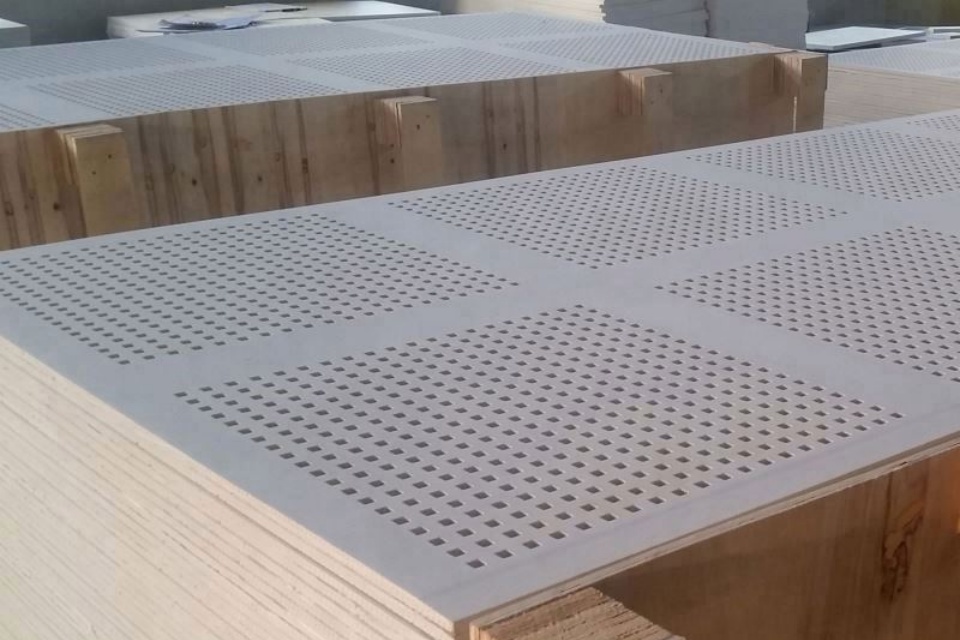

- UHMWPE / HDPE sheets

- Sometimes steel or lead plates

- Ice rink style panels for sliding or easy cleaning in some rooms

On paper, you count total thickness and say “OK, meets dose limit”.

But radiation does not behave so polite. It loves shortcuts.

In real projects, we often see:

- Layout meets spec

- Material quality is fine

- But one silly gap or penetration makes a dose hotspot behind the wall

That hotspot can be 10×, 100×, even 10 000× higher than the “bulk” field right next to it. This is what engineers call a streaming path.

Installation Gaps And Shielding Performance

Panel Joints And Expansion Gaps

For UHMWPE and ice synthetic panels, you always leave a little joint for:

- Thermal expansion

- Panel tolerance

- Quick replacement

Looks harmless. Client maybe say “It is only 3–4 mm, no big deal”.

But for fast neutrons and high energy photons, that small opening can behave like a tiny collimator.

| Gap width in joint | Total shielding thickness | Typical effect on local streaming dose |

|---|---|---|

| 0 mm (tight, filled) | 300–500 mm borated PE / concrete | No local hotspot, dose follows bulk design value |

| 2–3 mm straight gap | Same | Local dose at gap exit can be ~10–50× higher than bulk |

| 5–10 mm straight gap | Same | Local dose at gap exit can reach 100–10 000× bulk in worst cases |

| 5–10 mm stepped / labyrinth gap | Same | Peak dose much lower, often back within a few × of bulk |

Values are relative; real number depend on source energy, distance, and layout, but the ratio idea is correct.

“You can not treat joints as only cosmetic problem. For radiation they are the fast lane.”

Door Gaps And Air Gaps Around Frames

Shielding doors are another classic pain point:

- Door bottom gap for floor tolerance

- Side gaps between door leaf and frame

- Air pocket behind the door, inside the wall recess

If the door leaf is heavy but the frame gap is large, you basically build a labyrinth with no turns. Dose streams around the leaf, then leaks into the control side.

Some typical bad patterns:

- Big gap under the door because floor is not flat

- Door not fully closing, latch mis-aligned

- No compressible seal, only “visual closing”

For ice rink style rooms or test boxes lined with ice synthetic panels, you see similar issue at removable doors or hatches. The plastic surface looks nice, but the real question is: what is behind the panel, and how is the joint sealed?

Penetrations In Neutron And Gamma Shielding

Cable Trays And Pipe Penetrations

Real facilities need:

- Power cable trays

- Instrumentation conduits

- Water or cooling pipes

- Ventilation ducts

Every one of these is a potential shine path if you just drill a straight hole.

Common on-site shortcuts:

- Core drill a round hole, push pipe through, leave air all around

- Cut a rectangular slot for a cable tray, no sleeve, no extra shielding

- Multiple small holes close together, forming one “big” streaming channel in practice

You can map these issues in a small overview table:

| Penetration type | Typical on-site shortcut | Risk for streaming | Better practice |

|---|---|---|---|

| Single pipe | Straight hole, large annulus gap | Strong dose along pipe axis | Use sleeve, grout annulus, or add local thickening |

| Cable tray | Big rectangular cut in wall | Broad streaming path above tray | Labyrinth tray route, local heavy shielding around opening |

| Multi-pipe cluster | Many holes close together | Combined “effective” large opening | Use common sleeve block, fill around pipes, stagger positions |

| Inspection hatch | Simple steel cover on thin frame | Leak around frame, shine through thin plate | Thicker plate, step joint, compressible seal, shielding infill |

For borated PE and UHMWPE systems, you can still design block-type sleeves and “plug” pieces. These can be machined in factory by Dongxing Rubber and shipped as part of the kit, so the installer dont need to improvise on site.

Mitigation Strategies For Streaming Paths

Stepped Joints And Labyrinth Seals

The easiest way to kill a streaming path is: remove the straight line of sight.

For joints and doors, that means:

- Use stepped joints instead of straight butt joints

- Overlap panels (tongue-and-groove style)

- Add steel lips or UHMWPE tongues around doors and access hatches

- Use labyrinth route for cable trays and ducts (one or two 90° bends)

Even if the total thickness is the same, a stepped joint cuts the peak streaming dose by orders of magnitude in many studies.

“One bend is already much better. Two bends, the dose drop is huge.”

Field Grouting And Local Reinforcement

You will never get perfect blocks and perfect walls. So you plan for field corrections:

- Cement or polymer grout behind modules to kill air pockets

- Flexible, high-density seal strips in panel joints

- Local steel or lead “picture frames” around penetrations

- Extra borated PE layer at known hotspots found during commissioning

Here is a simple “checklist style” table that also sounds like industry talk:

| Hotspot source | Quick diagnostic | Typical fix on live project |

|---|---|---|

| Joint between modules | Scan with survey meter along seams, look for narrow spike | Inject grout, add overlap plate, or bolt an extra UHMWPE strip |

| Door gap | Measure with door both closed and slightly open | Add bottom step, adjust hinges, fit sealing profile or shim plates |

| Pipe penetration | High reading along pipe centerline | Add collar, grout gap, wrap pipe with local shield sleeve |

| Cable tray cutout | Broad hotspot above tray | Build small labyrinth with UHMWPE blocks, add lead or steel cover |

This kind of language feels real to maintenance guys. It is not academic, it is “what we actually do when the numbers look ugly”.

Quality Control For Ice Synthetic Panels And UHMWPE Shielding

Some practical rules for your buyers:

- Plan joints on paper, not on the floor

Decide joint pattern, expansion gaps and overlap design early. Dont let the installer “just cut where feels easy”. - Match panel system with shielding system

If the panel is mainly for skating surface or wear protection, make sure the shielding layer behind it is continuous. Avoid putting electrical boxes or pipe sleeves right under a joint line. - Tight joint tolerance

For ice synthetic panels from Dongxing Rubber and other UHMWPE sheets, control machining tolerance. A 1–2 mm designed joint with proper tongue-and-groove is much better than a random 5 mm saw cut. - Commissioning walk-down

After installation, do a “dose walk-down” with a survey meter where radiation is present, or at least a full visual walk-down. Look for:- Visible gaps

- Mis-aligned panels

- Open penetrations

- Un-sealed door frames

Small fixes at this stage are cheap. Later, when the line is running or the rink is open, changes cost you time and reputation, even if we dont talk detailed money.

Business Impact For OEM, ODM And Bulk Buyers

For OEM, ODM and wholesale clients, installation pitfalls are not only safety problem. They are also business risk:

- Extra shielding retro-fit

- Extra acceptance tests

- Extra paperwork with regulators

- Downtime of equipment or rink

If you supply a full package of:

- UHMWPE / HDPE plates

- Ice synthetic panels

- Borated PE blocks

This is exactly where a manufacturer like Dongxing Rubber can stand out:

- Engineering support on joint layout and penetrations

- Custom OEM / ODM blocks for sleeves, collars, and overlap strips

- Bulk supply for projects that need both ground mats, ice rink products, and shielding plates under one contract