-

Tian Dong Industrial Park, Decheng District Economic and Technological Development Zone, Dezhou City

Boron Content (5% vs 10%+): How It Changes Shielding & Cost

When you design a neutron shielding wall or door, one question pops up very fast:

“Do I stay with 5% boron, or do I pay extra for 10%+?”

On paper, more boron looks always better. In real projects, it’s not that simple. Shielding effect, cost, weight, and even install time all move at the same time.

Below we walk through how 5% vs 10%+ boron really changes neutron shielding and total cost, using language you can talk about in a project meeting, not only in Monte Carlo report.

Table of Contents

Neutron Shielding Basics: Hydrogen and Boron Working Together

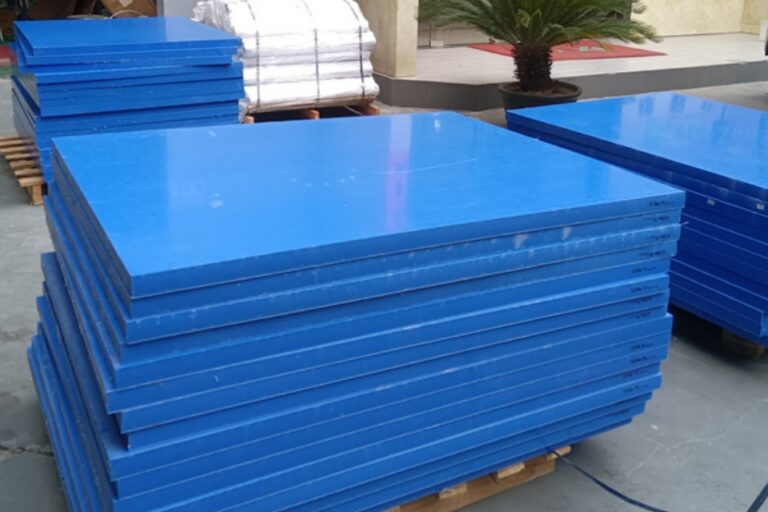

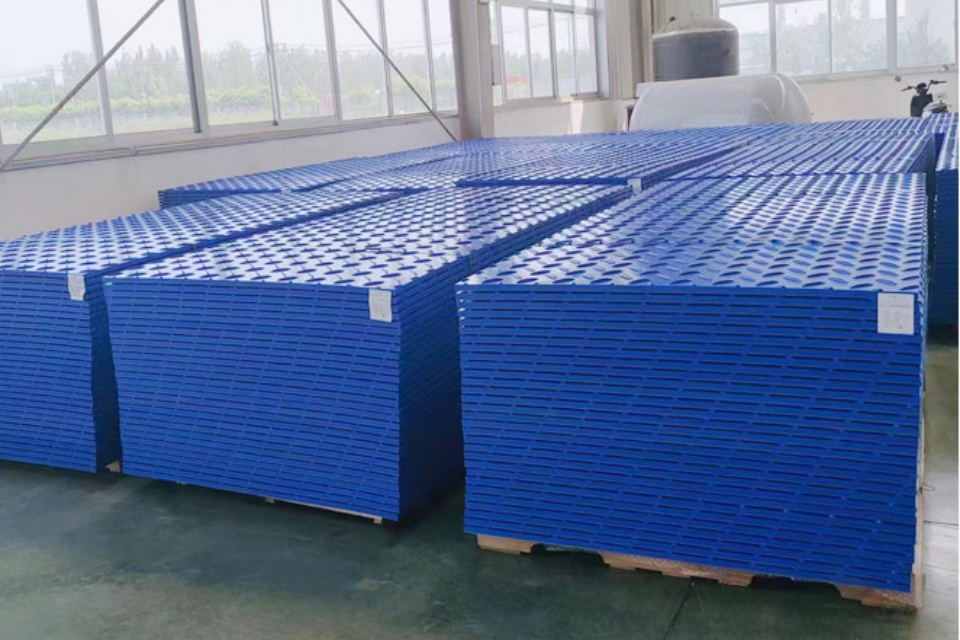

Most borated polyethylene plates use a HDPE or UHMWPE base. That’s basically the same family of material you see in ground protection mats, outrigger pads, and other heavy-duty PE parts.

The physics idea is simple:

- Hydrogen in PE slows down fast neutrons.

- Boron (mainly B-10) captures the slowed, thermal neutrons.

So the process is:

- A fast neutron hits the hydrogen atoms many times and loses energy.

- When it becomes a slow (thermal) neutron, boron “eats” it.

- In that capture, boron also throws out some γ rays you still need to manage.

Because Dongxing Rubber already works with high-performance UHMWPE & HDPE sheets, ground mats, and custom PE plates, we stay very close to this hydrogen side of the story every day, not only in theory but in real machining, drilling, and flatness control.

Neutron Shielding Performance at 5% Boron vs 10%+ Boron

You maybe think like this: “If 5% works, 10% must be two times better, 20% four times, right?” Sadly, physics don’t follow sales logic.

Fast neutron region

For fast neutrons, the main job is slowing them down. That job belongs to hydrogen, not boron.

- 5% boron PE already has lots of hydrogen.

- 10–30% boron PE still has hydrogen, but slightly less, because boron and fillers take some volume.

- So in many tests, the difference in fast neutron attenuation between 5% and 10–30% is quite small.

In other words, this kind of plate are not magic. For fast neutrons, thickness, density, and geometry matter more than just pushing boron number higher and higher.

Thermal neutron region

Once neutrons are slowed, boron becomes the star:

- 5% boron gives a very good level of thermal neutron capture.

- Around 10% boron can squeeze out some extra capture, especially in hot thermal fields.

- After a certain point, adding more boron gives smaller and smaller gain, because you are losing hydrogen and changing the structure.

In practice, many shielding engineers treat 5% borated PE as the “balanced default”, and 10–15% as a special tool when they need more performance in limited space.

Secondary Gamma Radiation From Boron Capture

There is one thing that many non-specialist teams forget in the first design round.

When boron captures a thermal neutron, it also releases capture γ rays (you see a bump around 0.48 MeV in spectra). If you push boron content high but don’t upgrade the γ shielding, you can move the problem from neutron dose to photon dose.

So:

- More boron = more neutron capture = more secondary γ.

- If you already work close to your dose budget, you must check the γ field after adding high-boron plates.

- Often you end up adding lead or other high-Z layers behind the borated PE. That means more cost, more weight, more anchors, more install headache.

This is one reason why “10%+ everywhere” sounds strong in marketing slide, but sometimes eats your safety margin in real dose calculation.

Cost Impact of Boron Content in Borated Polyethylene

We don’t put exact numbers here, but one trend is very clear from the market:

Every step up in boron content means a clear step up in material price and whole system cost.

Reasons are obvious:

- Boron compounds are much more expensive than base PE.

- High-boron PE needs more controlled mixing and processing.

- Scrap rate in machining can go up when the plate is more brittle or more abrasive.

- Transport and install of very heavy, thickiness plates cost more labor and hardware.

Qualitative comparison: 5% vs 10%+ borated PE

You can show something like this table in your own report to management, without doing detailed cost per kilogram:

| Parameter | 5% Boron PE Plate | 10–15% Boron PE Plate | 20–30% Boron PE Plate |

|---|---|---|---|

| Fast neutron attenuation | Good | Good to slightly better | Similar to 10–15% |

| Thermal neutron capture | High, well balanced | Higher, useful in hot thermal spots | Very high but with trade-offs |

| Secondary γ generation | Moderate | Higher | Highest |

| Material weight | Lower | Medium | High |

| Relative material cost | Baseline | Clearly higher | Highest, premium grade |

| Machining and drilling | Easier, more forgiving | Slightly more demanding | Most demanding, more tool wear |

| Typical use case | Doors, walls, general shielding | Compact shields, local hot spots | Special compact or research shields |

As you see, 5% is not “cheap and weak”. It sits in a very sweet spot for many real-world projects.

Practical Selection Scenarios for Borated Polyethylene Plates

Now let’s go away from theory and into real jobs you may face.

Neutron shielding for accelerator or therapy rooms

In many hospitals and research halls, you have:

- Large walls and doors

- Plenty of thickness available

- Tight budget and many other trades fighting for the same money

Here, 5% boron plates are usually enough:

- You can play with total thickness and layout.

- You keep plate weight reasonable for standard hinges and tracks.

- You don’t overload the γ side and still meet ALARA rules.

Going to 10%+ only makes sense if dose calculation shows a clear thermal neutron issue and structure space is really limited.

Compact neutron shielding around hot spots

Sometimes you work near:

- Collimator exits

- Beam dumps

- Local “shine” paths near penetrations

Here space is small, dose is nasty, and maintenance window is short. This is classic “hot spot” engineering slang.

In these tight, noisy locations, 10–15% boron PE can pay off:

- It lets you shave some centimeters of thickness.

- It helps to clean up thermal neutron peaks in narrow gaps.

- You accept higher material price because this is only a small area but very high risk.

Just remember to check the secondary γ and maybe add a thin high-Z layer. Otherwise your dosimetry guy will not be happy.

Mixed projects: ground logistics plus shielding

On nuclear, medical, or power-plant sites, you don’t only need “wall panels”. You also need to move heavy gear, temporary devices, casks and scaffolding across soft or dirty ground.

This is where the rest of your plastic portfolio comes in:

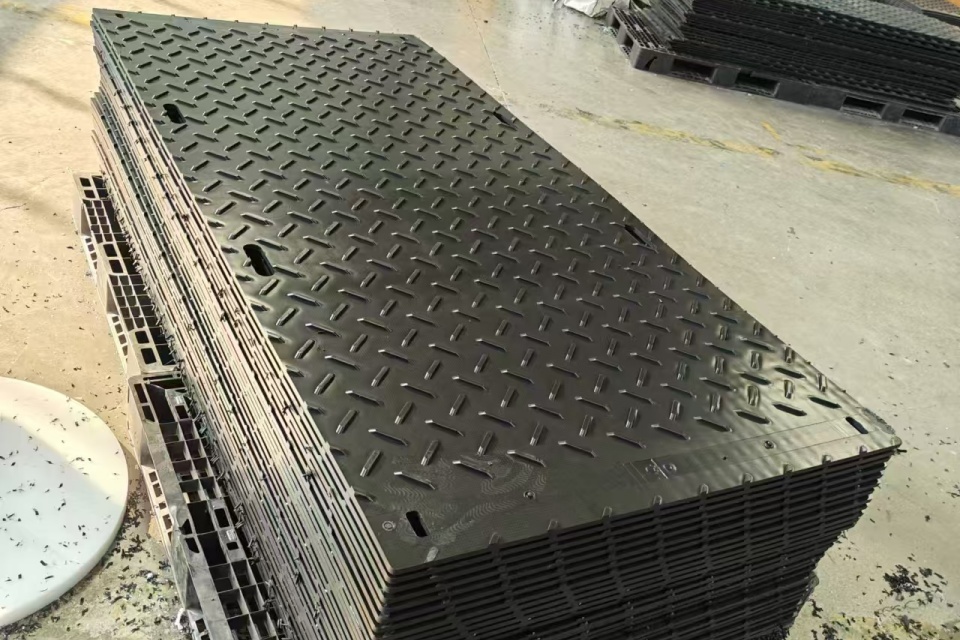

- Ground protection mats give you clean, solid access for cranes, trucks, and forklifts.

- Quick Mats let you drop a temporary roadway fast, without killing the soil or floor.

For example, Dongxing Rubber can supply UHMWPE ground mats for outside logistics and custom PE plates (including borated grades) for the actual shielding structures. One vendor, less finger-pointing when something don’t fit on site.

You reduce:

- Site damage

- Install time

- Random delays because one supplier’s mat can’t handle the wheel load

And you keep the neutron shielding design consistent with the same PE material know-how behind both products.

Ground Protection & Road Mats

Quick Mats

Simple Checklist: Stay With 5% or Move to 10%+ Boron?

When you sit with your team and need a quick decision, you can use a small decision list like this:

- Your neutron field is mixed, wall is thick, budget is tight

→ Start with 5% boron. In many cases this is enough and already industry standard. - You have very limited space and clear thermal hot spots in the calc

→ Consider 10–15% boron in those small critical regions only. - You see that secondary γ becomes the new problem

→ Don’t just keep adding boron. Add proper γ shielding and re-check the stack-up. - You need a lot of machining, drilling, inserts, big tolerances

→ 5% is friendlier. Very high-boron plates can be more brittle and harder to work with. - You also need ground access mats or big PE plates for equipment

→ Talk with a supplier like Dongxing Rubber that already does OEM/ODM UHMWPE & HDPE sheets, road mats, and engineering plastic parts. It saves you time on trial-and-error and reduces surprise cost later.

Closing Thoughts

Boron content is not just a pretty number in the datasheet.

- 5% boron is a strong, balanced choice for most neutron shielding walls and doors.

- 10%+ boron is a special tool for tight spaces and very high thermal flux areas, not a default for the whole facility.

- Cost, secondary γ, weight, and install work all change when you push boron higher.

If you treat boron level as part of a whole system design—together with γ shielding, structure, and even simple things like ground access and handling—you get a shield that works in real life, not only in simulation file.