-

Tian Dong Industrial Park, Decheng District Economic and Technological Development Zone, Dezhou City

Neutron Shielding 101: Why Hydrogen and Boron Work Together

If you work around reactors, cyclotrons, hot cells or isotope lines, you already know one thing: neutrons are a pain. They don’t behave like x-rays. Lead alone doesn’t fix the problem.

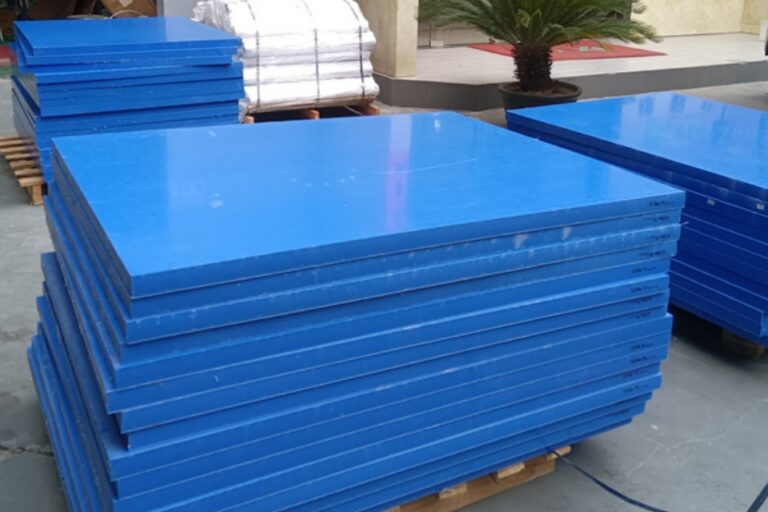

In practice, most smart shielding designs end up using some kind of hydrogen-rich plastic plus boron. That’s also where UHMWPE and HDPE plates, like the ones from Dongxing Rubber, quietly join the game – not only for ground protection mats, but also as the base for borated shielding panels.

Let’s walk through why hydrogen and boron are such a strong combo, and how that links to real projects and OEM/ODM work.

Table of Contents

Basics of Neutron Shielding and Hydrogen-Rich Materials

When a neutron comes out of a source, it usually starts as a fast neutron (MeV range). Before you can really “kill” it, you first need to slow it down to a thermal neutron (around room-temperature energy).

This is the classic two-step idea:

- Moderate (slow) the neutron – many elastic collisions with light atoms.

- Absorb the thermal neutron – a nucleus with a high capture cross-section takes it in.

Hydrogen is perfect for step one. Its nucleus has almost the same mass as a neutron, so each collision can remove a big chunk of the neutron’s energy. That’s why materials like:

- Water

- Paraffin

- HDPE and UHMWPE sheets

are all classed as “hydrogenous moderators”.

In simple words:

If you want neutrons to calm down fast, you throw a lot of hydrogen in their way.

Neutron Scattering in Hydrogen-Rich Polyethylene

Polyethylene (PE) – including UHMWPE – is basically long chains of carbon and hydrogen. The carbon sits in the backbone, hydrogen is all around it.

For fast neutrons, a thick UHMWPE plate does three useful things:

- Many scattering events: lots of H atoms = many hits.

- Strong energy loss per collision: energy drops quickly.

- Low activation: compared with many metals, PE will not “light up” with activation products so bad.

This is why you see thick PE blocks placed close to neutron sources in many layouts. Sometimes people call it the “poly wall” on their dose maps or in ALARA meetings.

Boron-10 Neutron Capture and Thermal Neutron Absorption

Hydrogen slows neutrons, but it doesn’t capture them aggressively. Once you have a big cloud of thermal neutrons, you need another actor on stage: boron, especially boron-10 (¹⁰B).

¹⁰B has a very high thermal neutron capture cross-section. When it captures a neutron, you mainly get this reaction:

¹⁰B (n, α) ⁷Li

The nice part for shielding:

- The energy stays mostly inside the material (α and Li ions deposit energy locally).

- You don’t create extremely hard secondary radiation. There can be some capture gamma, but it’s usually much easier to handle with a thin high-Z layer if needed.

So the job split becomes:

- Hydrogen → “moderator,” slows the neutron.

- Boron-10 → “absorber,” eats thermal neutron before it escapes.

Without boron, a PE wall can leave too many thermal neutrons leaking out the far side. With boron, you close the loop.

Hydrogen–Boron Synergy in Borated Polyethylene Sheets

In real engineering, people don’t want two huge layers if one engineered material can do both jobs. That’s where borated polyethylene – including borated UHMWPE – comes in.

Inside one plate, you get:

- A PE matrix (HDPE or UHMWPE) full of hydrogen for moderation.

- Boron additives (often B₂O₃ or B₄C) spread through the material for neutron capture.

Here’s a simple comparison you can use to explain it to a safety team or a procurement guy who isnt so nuclear-savvy:

| Material Type | Main Role in Shielding | Hydrogen Content | Boron Content | Typical Use Case |

|---|---|---|---|---|

| Pure HDPE / UHMWPE plate | Fast neutron moderation | High | ~0% | “Poly wall” around source, pre-moderator in shielding stack |

| Borated PE (e.g. 5% B) | Moderation + thermal neutron capture | High | Low–medium | Main neutron shield panels, doors, hot-cell walls |

| Concrete (no boron) | Structural + some neutron + gamma mix | Medium–low | ~0% | Building structure, far field bulk shielding |

| Borated concrete | Structural + neutron capture | Medium–low | Low–medium | Thick biological shield with improved thermal neutron control |

The story is simple:

First, hydrogen slows neutrons down.

Then, boron stops them for good.

All in one piece of plastic that you can machine, drill, and mount very similar like any other UHMWPE engineering plate.

UHMWPE and HDPE Plates as Neutron Shielding Substrates

The same know-how that lets Dongxing Rubber make tough ground mats that carry heavy equipment can also support borated UHMWPE or HDPE plates for neutron shielding use.

Key reasons UHMWPE works so well as a shielding substrate:

- High hydrogen content → strong moderation capacity.

- Excellent impact and wear resistance → panels survive handling, forklifts, temporary installations on site.

- Good machinability → you can CNC cut, drill, and chamfer edges for safer handling, just like your other PE plates.

- Low water absorption and chemical resistance → stable in damp, dirty, or slightly corrosive sites, like industrial plants or temporary “hot zone” around a NDT source.

From Ground Protection Mats to Radiation Shielding Panels

Think about a customer who already buys Dura Mats from you for:

- pipeline spreading yards,

- crane access roads,

- temporary wind farm pads.

Now the same customer wins an isotope production project or a neutron testing lab job. Suddenly they need modular shielding walls that:

- can be moved by forklift,

- can survive outdoor storage,

- and still do the neutron job.

Here you can offer:

- borated UHMWPE plates as standard modules;

- custom tongue-and-groove edges, lifting holes, or steel frame;

- OEM/ODM logo, color, and size;

- sample plates in a few weeks and mass production in normal 3–20 day window, similar to your other plastics business.

You speak the same industrial language: load rating, laydown yard, mobilization, temporary works, not only nuclear physics.

Design Considerations for Neutron Shielding with PE Plates

When you help an engineer size a shield, they care about dose on the cold side and layout of the whole system. But a simple “rule-of-thumb” table helps start the conversation:

| Parameter | Pure HDPE Plate (Moderator Only) | Borated PE Plate (Moderator + Absorber) |

|---|---|---|

| Main function | Slow fast neutron | Slow + capture thermal neutron |

| Typical boron content | 0% | ~1.5–5% (by weight) |

| Thermal neutron half-value layer | Larger thickness | Smaller thickness |

| Mechanical strength / impact | Very good | Very good (slightly changed by fillers) |

| Typical design use | First moderation layer | Main neutron shield wall or panel |

Half-value layer here is a practical design idea: thickness that cuts thermal neutron flux roughly in half. Exact numbers depend on energy spectrum and geometry, so in real design you always run a transport calculation, but this table give a sense for customers.

You can also talk about usual industry black words:

- “source term” (what neutron output you have),

- “dose budget” for each room,

- “shutdown dose rate” behind the shield,

- temporary “poly-boron wall” for outage or refuelling windows.

That kind of language shows you are not only selling plastic; you understand the job site reality.

Industrial Use Cases and OEM/ODM Neutron Shielding Projects

Here are some real-world scenes where hydrogen + boron panels make sense, and where a supplier like Dongxing Rubber can bring value beyond just raw material:

- Cyclotron and PET-CT facilities

- Borated UHMWPE panels used around the vault, in maze areas, or as local shields around targets.

- Need clean machining, smooth chamfers, and sometimes stainless inserts for fixing.

- Research reactor beamlines and hot labs

- Sliding shield doors or movable blocks combining borated PE with steel framing.

- Frequent re-configuration, so weight and handle design matter a lot.

- Industrial neutron radiography and NDT

- Temporary shielding around test bunkers.

- Customers like modular blocks that can be stacked like “lego”, with tongue-and-groove or pin connections.

- Isotope production skids

- Compact shields around target stations and transfer lines.

- Require precise CNC cutouts, embedded threaded inserts, and clear labeling for installation crews.

Because you already support bulk orders, OEM/ODM, and customized PP/PE products and MG engineering plastic sheets, you can position neutron-shielding plates as just another branch of your engineering plastic solutions, not a totally new world.

Instead of only saying “we sell borated PE sheet”, you can say:

- we design the module size to match your hot cell layout,

- we machine lift points and fixing holes,

- we deliver batch production with repeatable QC,

- we answer fast when the safety team updates the dose map and needs a quick change.

That solves real buyer pain points, not just physics problem.

Conclusion: One Simple Story for Your Customer

When you strip away the equations, the story of neutron shielding is very short:

- Hydrogen slows neutrons down fast.

- Boron-10 captures the slow neutrons efficiently.

- Lead-boron polyethylene plates and boron UHMWPE sheets put both in one strong, machinable, industrial-grade panel.

For a manufacturer like Dongxing Rubber, already known for ground protection & road mats, Dura Mats, and PE engineering sheets, stepping into neutron shielding panels is not a big jump. It’s the same polymer toolbox, just tuned to a different scene – from muddy crane pads to quiet, thick walls that keep dose under control.

If you talk to your clients in this simple way – hydrogen moderates, boron captures, PE carries the load – they wont get lost in jargon, but they will remember why they need more than just a slab of lead.