-

Tian Dong Industrial Park, Decheng District Economic and Technological Development Zone, Dezhou City

Edge Finishing & Chamfers: Safer, Smoother Material Handling

When you move heavy plates all day, you don’t care about “nice theory”.

You care about hands, forklifts, and downtime.

Sharp PE edges cut gloves, scratch steel frames, and chew ropes.

So in Dongxing Rubber we talk a lot about one “small thing” that changes a lot:

edge finishing and chamfers on UHMWPE & HDPE parts.

This article goes through why we do it, how we do it, and what it means for your plant and your customer.

Table of Contents

Why Sharp Edges Are a Hidden Handling Risk

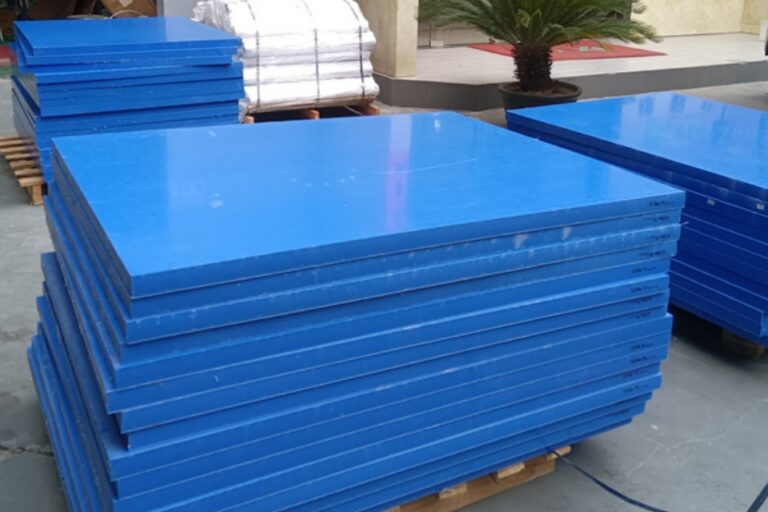

Fresh-cut UHMWPE or HDPE sheets look clean.

But touch the edge with bare hand, you know the truth.

- Workers get small cuts and “paper-cut” style wounds.

- Forklift drivers don’t want to push stacks too tight.

- Edges scratch painted steel frames, pallets, or cargo.

- In ports, fender pads with knife edges can even damage mooring ropes and rubber fenders.

Most buyers only put “thickness, size, color” in the drawing.

Edge condition is empty.

Then later they complain:

“Material is okay, but our guys hate to handle it.”

This is exactly the pain point edge finishing solve.

Edge Finishing Options: Chamfer, Radius, Deburr

For UHMWPE & HDPE sheets and fender pads, we usually talk about three levels:

Simple Deburring

Basic step after cutting.

We remove big burrs and chips from the saw or milling.

- No more hanging plastic strings.

- Lower risk of big cuts, but still a bit sharp when you squeeze hard.

Good for hidden parts that nobody will touch often.

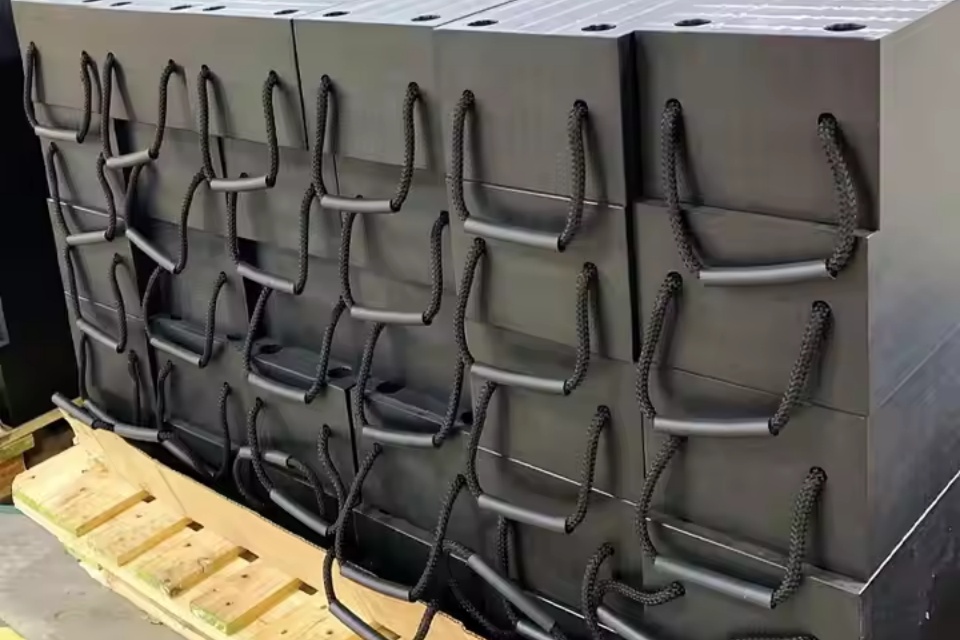

Chamfered Edges

Here we cut a small 45° slope on the edge.

Typical size for handling safety:

- 0.5–1.0 mm × 45° on standard plates.

- Bigger chamfer on thick fender pads or dock bumpers.

This small slope works like a guide.

- Sheet slides easier into racks and frames.

- Edges don’t bite your palm when you push the plate.

- In warehouse, stacks are more “friendly” for hand pick.

Edge Rounding / Radius

For more demanding jobs, we don’t want just a slope,

we want a soft radius:

- R1–R2 mm on exposed edges for outdoor sheets, fender pads and bumper faces.

- Helps coating or marking stick better at the edge.

- No “knife feeling” at all, even if you pull hard.

Ports, truck beds, transfer chutes, ice rink dasher boards – these places love radius edges.

Typical Chamfer and Radius Sizes in Industrial Practice

Below is a simple table you can show in your drawing review meeting.

Values are typical ranges we often use in Dongxing Rubber projects for UHMWPE & HDPE parts.

| Edge condition | Typical size (example) | Handling & safety effect | Where we usually use it at Dongxing Rubber |

|---|---|---|---|

| As-cut, deburred only | 90° edge, burrs removed | Still a bit sharp; gloves recommended; more scratch risk on metal frames | Hidden faces of large ground mats, spacer plates |

| Small chamfer | 0.2–0.5 mm × 45° | Edge less aggressive; ok for occasional manual touch | Side edges of sheets that go into tight frames |

| Standard chamfer | 0.5–1.0 mm × 45° | Much safer in daily handling; easier sliding between plates | UHMWPE HDPE Sheets & Plates for conveyors, lining panels |

| Rounded edge (radius) | R1–R2 mm | Very comfortable to grip; hard to cut hand; kinder to ropes and straps | UHMWPE Fender Pads, dock bumpers, exposed board edges |

| Heavy radius / profiling | >R2 mm, custom shaping | Best for impact and repeated contact; no sharp spots | Special fender blocks, truck / trailer side protectors |

You don’t need crazy theory here.

Just decide: who will touch this edge and how often?

Then choose one line from the table and lock it in your drawing.

What This Means for UHMWPE & HDPE Sheets in Real Handling

Think about a simple job:

you unload a pallet of thick HDPE plates for a lining project.

- As-cut, sharp edges: workers move slowly, they keep distance, they drop boards instead of sliding them.

- Same boards with standard chamfer or radius: people grab closer, adjust by hand, slide panels into place without fear.

For UHMWPE HDPE Sheets & Plates, edge finishing helps in:

- Truck loading – plates slide on and off easier, less strap damage.

- Warehouse stacking – stacks look more neat, less wrap tearing.

- On-site install – sheets guide themselves into the frame or channel, less hammer, less swear words.

And because UHMWPE has very low friction,

a rounded or chamfered edge makes it even more “滑溜” on steel.

So your material flow literally become smoother.

Safer, Smoother Handling With UHMWPE Fender Pads

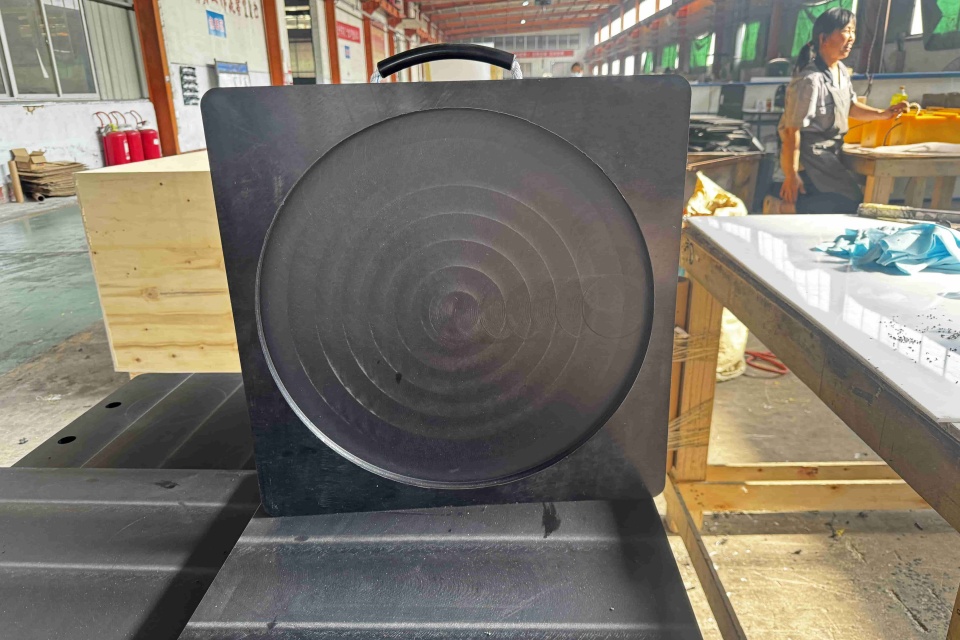

Now imagine UHMWPE Fender Pads in a port.

Here the edge story is even more sensitive.

Bad edge:

- Sharp PE corners can cut mooring ropes and belts.

- Pads may dig into rubber fenders and cause early wear.

- When workers line up pads on the quay wall, they fight with heavy blocks that scratch everything.

Finished edge with radius:

- Rope slides along the pad instead of getting cut.

- Contact area with ship or rubber fender is more stable.

- Installers can push and roll the pad into position with less risk.

Many buyers only ask: “What thickness? What color? Virgin or regrind?”

In Dongxing Rubber we push one more line in the conversation:

“Let’s define your edge condition, so your guys in port don’t hate this project later.”

This sounds like small detail, but client can feel you talk real field,

not just catalog English.

How Edge Finishing Adds Business Value for OEM / ODM Buyers

You don’t sell only plastic.

You sell less trouble for your own customer.

For OEM and ODM projects, especially in:

- Ground protection & road mats

- Ice rink boards and dasher systems

- MG engineering plastic sheets, PP/PE plates

a clear edge spec can:

- Reduce field complaints

Fewer “it cut my hand” phone calls from installers. - Cut hidden rework

Your customer’s team doesn’t stand around with grinder and sandpaper to “fix” your parts. - Look more premium

Rounded and chamfered edges make PE products look more engineered, less “raw block”. - Support your price level

You don’t need to talk numbers, just talk value:

“Our UHMWPE panels come with finished edges ready for handling and install.”

When you print “High-Performance Engineering Plastic Products Manufacturer”,

things like edge finishing make that line true, not only marketing text.

How to Order UHMWPE With the Right Edge From Dongxing Rubber

When you send a drawing or even just an email sketch,

you can keep it very simple:

- For general UHMWPE HDPE Sheets & Plates: “All exposed edges: 0.5–1.0 mm × 45° chamfer, remove burrs.”

- For UHMWPE Fender Pads and high-touch edges: “All outer edges: radius R1–R2 mm, corners rounded, no sharp spots.”

We then match this with our machining process:

CNC milling, edge rounding tools, small hand finishing where needed.

Is it perfect every time? To be honest, sometimes we also adjust on first batch,

because real site feedback is king.

But we treat edge finishing as part of design,

not a random “maybe we deburr if we have time”.

Closing Thought

Edge finishing and chamfers look like a tiny detail on a 2D drawing.

In real life they decide if your UHMWPE product feels safe, smooth, and pro,

or feels like cheap raw plate.

If you handle material every day, you know which one you want.

So next time you spec UHMWPE sheets, fender pads, or other PP/PE products,

write one more short line on the drawing about edges,

and let Dongxing Rubber do the “dirty work” in the factory,

not your team on site with a file and bad mood.