-

Tian Dong Industrial Park, Decheng District Economic and Technological Development Zone, Dezhou City

Noise & Vibration Damping: Replacing Metal Wear Plates With UHMWPE

You probably don’t wake up thinking, “Today I must fix wear plates.”

But when the line is noisy, operators complain, and bearings keep failing, the real root cause very often sits right there: metal wear plates.

In many plants, swapping metal plates for UHMWPE wear plates is one of the easiest ways to cut noise and vibration without rebuilding the whole machine. Let’s walk through why, where it works best, and where metal still makes sense.

Table of Contents

Why Metal Wear Plates Create Noise And Vibration

Metal is stiff, hard, and loud. That sounds simple, but it drives three big problems:

- Metal-on-metal contact = high noise

Chain, belt, or parts slide on steel. Every micro-impact goes straight into the plate, then into the frame, then into the air as noise. At higher line speed, that rattling only gets worse. - Steel transmits vibration instead of damping it

When a roller hits a joint, or a bucket slams down, the steel plate behaves like a bell. It doesn’t eat energy. It passes it along. Vibration travels into the frame, supports, even the floor. - High friction and stick–slip

Metal surfaces are rougher and grab more. You get stick–slip motion: the part sticks, then suddenly jumps. That jump makes a sharp “crack” sound and more vibration.

So you end up with a classic shop-floor complaint:

“The line runs, but it screams. People have to shout, and the gearbox sounds angry.”

How UHMWPE Wear Plates Reduce Noise And Vibration

UHMWPE (ultra-high molecular weight polyethylene) behaves totally different from steel. For noise and vibration, three material features really matter.

UHMWPE Low Friction And Self-Lubrication

UHMWPE has a very low coefficient of friction. Parts slide instead of stick. That means:

- Less squeak and rattle from sliding components

- Less drive torque needed to move product

- Less heat and less wear on chain and belt

In many conveyor and chute scenario, UHMWPE almost acts like a built-in lubricant. You don’t need to flood the area with oil or grease, which is nice for food, packaging, or dusty enviroment.

When we design PP/PE products at Dongxing Rubber, we always pay attention to this low-friction behavior. It’s a big reason why our UHMWPE sheets and HDPE parts run quiet even when the line speed goes up.

Impact Absorption And Vibration Damping In UHMWPE

UHMWPE is still tough and wear-resistant, but it has more “give” than steel. That small elasticity lets it:

- absorb a part of the impact energy

- turn vibration into a tiny amount of heat inside the material

- stop the frame becoming a big sounding board

Result: vibration level go down, structure-borne noise goes down too. Operators feel less shaking on handrails and platforms.

Noise Reduction In Real Production Lines

When plants replace a metal wear plate with a UHMWPE plate or liner, they often see:

- lower perceived noise (no more “metal clash” sound)

- smoother chain motion

- fewer emergency stops due to jam or misalignment

You don’t always measure dB with a meter, but the team will tell you very fast:

“Hey, this area is finally not killing my ears.”

Metal vs UHMWPE Wear Plates For Noise & Vibration

| Item | Metal Wear Plates (Steel) | UHMWPE Wear Plates | Noise & Vibration Impact |

|---|---|---|---|

| Noise level | Metal-on-metal contact, sharp impact noise, very easy to go into “shout to talk” zone near the line. | Soft contact feel, no metal clash, sliding sound is much lower and duller. | UHMWPE cuts the high-frequency “ringing” noise and makes the line sound softer. |

| Vibration damping | Very stiff, passes vibration straight into structure and floor. | Has internal damping, eats part of the vibration energy. | Less shaking of guards, platforms, and anchor bolts; fewer “mystery rattles”. |

| Friction & lubrication | High friction, needs constant grease or oil; stick–slip and squeaks are common. | Low friction, self-lubricating surface in many scenarios. | Less squeak, smoother motion, more stable speed under load. |

| Wear on moving parts | Can chew chains, belts, and sliders; shortens service life. | Gentle to chain and belt, surface “slides” not “cuts”. | Lower vibration from worn or stretched chain, less unsteady running. |

| Weight | Heavy, difficult to handle during shutdowns. | Much lighter than steel at same size. | Easier, faster swaps reduce downtime during maintenance windows. |

| Typical best use | Very high temperature, extreme point loads, some impact zones. | Medium load, low to medium temperature, noise-sensitive areas. | Good fit for conveyors, chutes, guides, and lining in high-noise zones. |

Real-World Scenarios: Conveyors, Chutes, And Mobile Equipment

Let’s talk about places where you really feel the difference when you replace metal wear plates with UHMWPE.

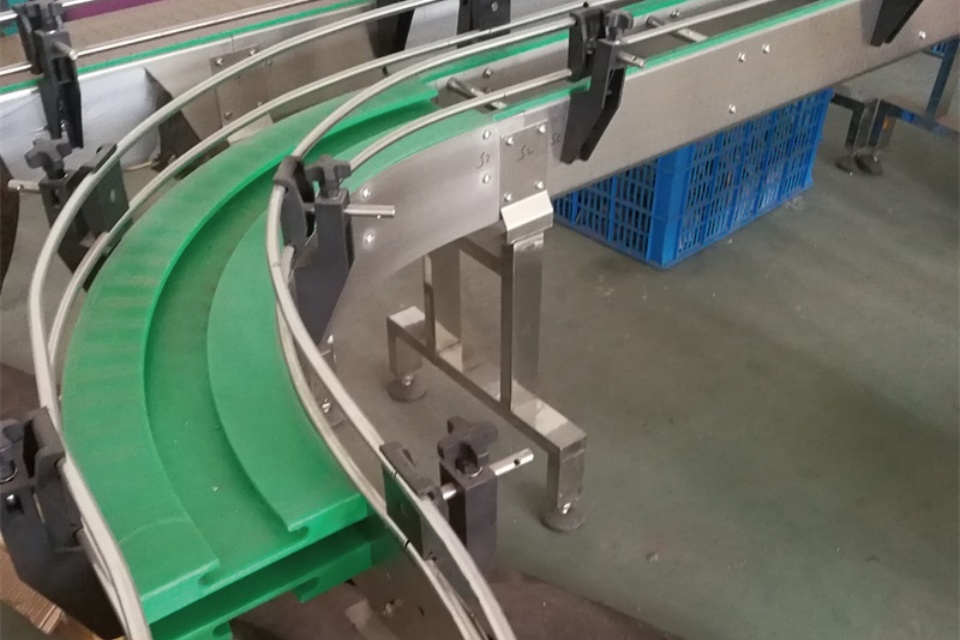

Conveyor Transfer Points And Chain Guides

At transfer points you often have a noise hotspot:

- bulk material drops

- belt slaps

- chain hits the wear bar

Switching to UHMWPE wear strips or liners can:

- soften every impact

- reduce carry-back sticking to the plate

- quiet down the continuous “clack-clack” of chain links

If you use custom UHMWPE sheets or engineering plastic sheets from Dongxing Rubber, we can machine slots, countersinks, and grooves so your maintenance team just bolt-on the new plates during one short shutdown.

Chutes, Hoppers, And Silos

Metal chutes with sharp corners are a classic source of drumming noise. Product hits one spot again and again, like a hammer.

UHMWPE liners change the picture:

- bulk material flows more like on ice

- less build-up and rat-holing

- less impact stress at the same hotspot

In many plants, just lining the first 1–2 meters of a metal chute with PP and PE materials already cuts both noise and sticking problems in that zone.

Mobile Equipment And Outrigger Pads

On cranes, trucks, or mobile platforms, metal contact points also transmit vibration straight into the ground or frame.

UHMWPE outrigger pads and ground protection mats help spread the load and soften the contact. People feel less shaking, and you hear less structure-borne noise when equipment moves or stabilizers set down.

Design Limits: When To Keep Metal Wear Plates

UHMWPE is not magic plastic. There are still clear limits, and saying this honestly makes your design more trustable.

You should keep metal wear plates or hybrid design when:

- Temperature is high (close to or over UHMWPE safe range)

- Contact pressure is very high on tiny points

- Impact is extreme and can cut or punch through the plate

- The plate must carry serious structural load, not only guide or slide

In those scenario, you can still use UHMWPE as a sacrificial liner or insert, while the metal behind stays as the “backbone”.

Dongxing Rubber often helps OEM and ODM clients combine PP/PE products with steel backing plates, so they get both strength and low-noise sliding surface in one set-up.

Practical Checklist For Switching From Metal To UHMWPE

If you’re thinking about replacing metal wear plates with UHMWPE, use this quick checklist:

- Where is the noise hotspot?

Stand there with operators. Is it a transfer point, chute bend, or chain guide? - What really touches the plate?

Chain, belt, product, or steel part? Sliding or impact? Continuous or only sometimes? - What is the temperature and environment?

Is it hot, near steam, or chemical splash? Or more “normal” plant conditions? - How much load does the plate carry?

Only guiding and sliding, or also supporting heavy structures? - What plate thickness and grade do you need?

UHMWPE and HDPE come in many grades. For high-wear and low noise, our PP/PE products line covers sheets, pads, and custom machined parts. - Do you need custom machining, OEM/ODM, or just stock sheets?

Dongxing Rubber focuses on bulk wholesale, customization, OEM/ODM for ground mats, rink boards, engineering plastic sheets, and other UHMWPE & HDPE parts. So you don’t fight with cutting, drilling, or tapping on site.

Final Thought

If your line is loud, don’t only blame the motor or gearbox. Very often the “real noise source” is simple: metal wear plates and metal contact everywhere.

By replacing key metal wear plates with UHMWPE wear plates or liners, you:

- lower noise

- cut vibration

- protect chains, belts, and frames

- make life easier for your team

And you can do it step by step, station by station, instead of a big rebuild.

When you’re ready to look at actual parts and not just theory, you can start from your high-noise zones and match them with the right HDPE components or UHMWPE sheets. That’s where Dongxing Rubber really brings value: turning a noisy, “angry” line into something calm enough that people can talk next to it, not shout.