-

Tian Dong Industrial Park, Decheng District Economic and Technological Development Zone, Dezhou City

Can UHMWPE Be Bonded Reliably? Surface Prep + Adhesive Options

You can bond UHMWPE. Not with magic. With good surface prep, the right adhesive chemistry, and a clean, repeatable process window. In this guide, I’ll keep it plain, hands-on, and tied to real shop floor use—especially for Ice Synthetic Panels used in rinks and training tiles.

Quick takeaway: UHMWPE has low surface energy. Fix wet-out first (activation), then pick an adhesive built for low-surface-energy (LSE) plastics. Do those two right and the joint holds up.

Table of Contents

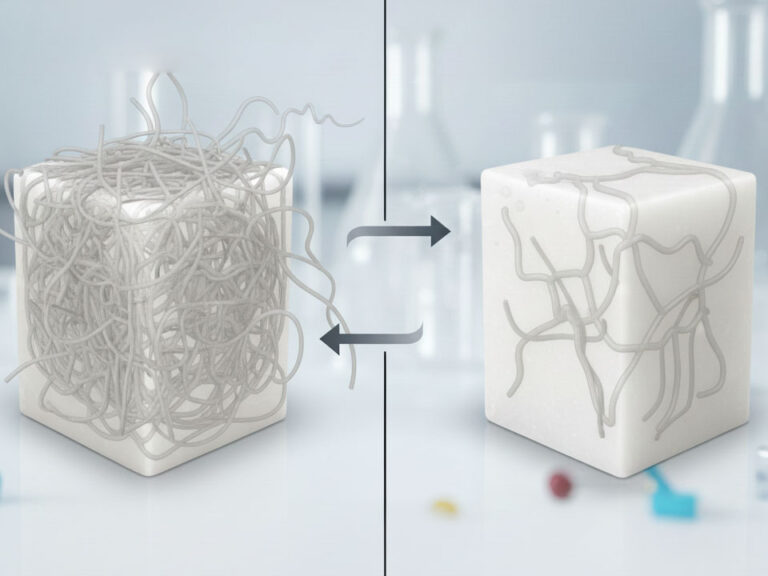

Why UHMWPE Is “Hard to Glue” (low surface energy)

- UHMWPE’s surface acts like a waxed car. Adhesive wants to bead up.

- Low wet-out → poor intimate contact → weak adhesion, even if the adhesive itself is strong.

- So we change the surface. We activate it, add some polar groups, and give the glue something to grab.

Keywords you care about: low surface energy (LSE), wet-out, surface activation, bondline, lap-shear, T-peel, dwell time.

Surface Preparation Options (ranked by practicality)

1) Atmospheric Plasma / Corona Treatment

Raises surface energy fast. Clean and dry process. Good for sheets and extrusions.

Shop note: Treat → bond soon. Activation decays over time.

2) Flame Treatment

Pass a clean flame at the right distance and speed. Simple gear. Fast cycle.

Watchouts: Too hot or too slow and you “glaze” or warp edges.

3) Light Abrasion + Solvent Wipe

Very light scuff to increase real area and remove mold release. Then wipe with approved solvent.

Tip: Don’t over-roughen. Deep scratches can become crack starters.

4) Chemical Etch (rare in production)

Aggressive and messy. Can boost energy a lot but brings safety and compliance headaches. Use only if you know what you’re doing.

Adhesive Options for LSE Plastics (what actually sticks)

Structural Acrylics for LSE

Two-part acrylics formulated for PP/PE/UHMWPE. Good lap-shear and peel. Work with minimal pretreat, but still better after plasma/flame.

Cyanoacrylate + PO Primer

Fast fixture. Good for small parts, shims, quick jigs. Use polyolefin (PO) primer to make it bite.

Limit: Not the best for high peel/impact on big panels.

Modified Polyolefin / Hybrid Systems

Some hot-melts and hybrids wet UHMWPE better than standard grades. Useful for panel assembly with flexible joints.

Epoxies

Great on metals and many plastics, but not ideal on untreated UHMWPE. Can still work after activation plus proper primer, with design help (bigger bond area, lap joints, fillets).

What Works Best Where? (use-case led)

- Rink tiles / training squares / dasher board liners: structural acrylic + plasma or flame.

- Edge trims, logos, protectors: cyanoacrylate + PO primer for speed; switch to acrylics if loads rise.

- Ground mats, anti-slip caps: hybrids or acrylics; design generous overlap and a flexible bondline.

We supply UHMWPE Ice Synthetic Panels and can prep edges to help bonding consistency. If you need OEM/ODM runs, Dongxing Rubber can align the activation step with your line’s takt time—no fancy drama, just a stable SOP. We also stock UHMWPE & HDPE sheets for custom fixtures and jigs around the bond area.

Comparison Table: Prep + Adhesive Pairings (quick selector)

| Goal / Scenario | Surface Prep | Adhesive Type | Fixture Time* | Durability | Notes |

|---|---|---|---|---|---|

| Large panel-to-panel joints (rink tiles) | Plasma or flame + light abrasion | LSE structural acrylic | Short to moderate | High | Best mix of peel + impact; good outdoors if sealed |

| Small clips, labels, guards | PO primer | Cyanoacrylate | Very short | Medium | Fast builds; not for high peel |

| Mixed substrates (UHMWPE to aluminum) | Plasma + degreased metal | LSE structural acrylic | Moderate | High | Add fillet; design for shear |

| Flexible seams, low stress | Light abrasion | Hybrid / modified polyolefin | Short | Medium | Good wet-out, easy application |

| Lab repair / emergency fix | Minimal (clean only) | Cyanoacrylate + primer | Very short | Low-Med | Field patch; upgrade later |

Process Window That Actually Holds Up

- Clean first. Remove release agents, dust, fingerprints.

- Activate. Plasma or flame. Keep process parameters tight: distance, speed, and number of passes.

- Bond quickly. Don’t wait hours. Activation ages.

- Control bondline thickness. Use spacers or beads. Too thin → brittle; too thick → creep.

- Pressure + fixturing. Even squeeze, no starved joints.

- Cure to spec. Respect dwell and full cure before load. I know, it’s tempting to rush—don’t.

- Seal edges if outdoors. Better moisture and freeze-thaw stability.

Tiny language note: yes, “it do works” when you keep the window tight.

Design Tips You Can Use Tomorrow

- Favor shear, reduce peel. Use lap joints, not butt joints. Add a small radius fillet.

- Match thermal movement. UHMWPE moves more than metal. Add slots or floating tabs.

- Bigger footprint beats thicker glue. Increase overlap area before you try to go super-thick.

- Test the worst case. Coldest temp, wet surface, rushed operator. If it passes there, it’s robust.

Quality Checks (simple but powerful)

- Dyne marker or contact angle spot-check right after activation. If the ink beads, your process drifted.

- Witness coupons on each batch. Same prep, same cure, quick lap-shear pull or peel check.

- Peel-and-look: after manual peel, the failure tells the truth.

- Cohesive failure in adhesive: good adhesion, maybe adjust thickness.

- Adhesive cleanly lifts from UHMWPE: surface energy too low; fix activation.

- Substrate tear (rare on UHMWPE): overachiever, but watch for stress risers.

Real-World Example: Ice Training Tile Panel

- Part: UHMWPE Ice Synthetic Panels for home training.

- Joint: Panel-to-panel connectors and underside ribs.

- Prep: Light abrasion on glue zones → plasma pass → immediate bonding.

- Adhesive: LSE-grade two-part acrylic, controlled bead (bondline ~thin-medium).

- Fixturing: Simple clamps with uniform pressure; quick check with feeler gauges.

- Outcome: Stable peel across seams, no cold-weather pop-offs after cycles.

We keep the activation and bonding in one cell, so no aging of the activated surface—this small detail saves many headaches.

If you also integrate edges with ice rink products like dasher liners or kick plates, sync the prep so panels and trims see the same treatment window. For outdoor installs on training decks, consider ground protection mats to keep substrates flat during cure.

Common Mistakes

- Bonding long after activation. Surface “goes to sleep.”

- Starved joints. You pressed too hard or had no spacers.

- “Epoxy fixes everything.” Not on untreated UHMWPE.

- Over-roughening. Deep scratches = stress concentrators.

- Dirty rags and mystery solvents. Use approved cleaners, lint-free wipes.

Where We Fit In (OEM/ODM, bulk supply, fast samples)

High-Performance Engineering Plastic Products Manufacturer is our thing. We make UHMWPE & HDPE sheets, ice rink products, ground mats, and more. For wholesale buyers and customization teams, we handle custom sizes, batch runs, OEM/ODM, and bulk purchasing. Samples go out fast; production runs planned to your slot. Dongxing Rubber supports private-label requirements and can integrate activation + bonding steps into your SOP if you need a turnkey path. Need fast-to-ship panels or outdoor practice tiles? We also provide Quick Mats and Dura Mats for staging areas, plus UHMWPE sheets for jigs and fixtures.

Mini FAQ

Q: Can I skip activation if I use LSE acrylics?

A: Sometimes it sticks, but margins get thin. Do activation if you can. It’s cheap insurance.

Q: Screws or glue?

A: For removable panels, use screws + glue dots. For permanent seams, use full structural bonds with designed overlaps.

Q: Outdoor freeze-thaw?

A: Control bondline thickness, seal edges, and test the worst chill. Don’t rush cure in cold weather.

Summary

UHMWPE can be bonded reliably. Treat the surface (plasma or flame), choose an LSE-capable adhesive, and lock a tight process window. Design joints for shear, control the bondline, and verify with quick checks. Do that and your rink tiles, guards, and mats stay put—even when winter says hello.