-

Tian Dong Industrial Park, Decheng District Economic and Technological Development Zone, Dezhou City

Coefficient of Friction Showdown: UHMWPE vs Nylon vs POM vs PTFE

You care about glide, wear life, and noise. I get it. Friction decides whether a panel runs smooth or a board chatters like crazy. In this friendly face-off, we’ll compare UHMWPE, Nylon (PA), POM (Acetal), and PTFE using plain talk, real ranges, and quick tips you can use on the shop floor—right now.

TL;DR: PTFE has the lowest friction. UHMWPE balances low friction with outstanding wear. POM wins where PV (pressure × velocity) is higher and tolerances matter. Nylon is tough and modifiable (oil-filled grades help), but watch moisture.

Table of Contents

Why “coefficient of friction” (COF) really matters in sports boards and conveyors

In rinks, conveyors, and chute liners, COF drives three things:

- startup torque; 2) energy draw; 3) wear and squeal.

Lower COF can cut stick-slip, but it doesn’t always mean longer life. For example, PTFE slides like ice but can wear faster under load; UHMWPE might slide a tiny bit “slower,” yet it laughs at abrasion.

If you build or upgrade floor ball dasher boards, the panel’s COF controls puck/ball speed and the “feel” on impact. That’s why many teams ask us about surface finish, counterface roughness (Ra), and PV limit—the trifecta of tribology shop talk.

Want boards that move fast but still last? Check our Floor Ball Dasher Boards page—yes, we customize.

Typical friction numbers (dry, against polished steel; ambient)

Note: Real results depend on surface roughness, load, speed, humidity, and lubrication. Use these as practical ranges for early selection and then verify on your line.

| Material | Typical Static μs | Typical Kinetic μk | What it means in practice |

|---|---|---|---|

| PTFE | 0.08–0.10 | 0.05–0.08 | Easiest starting and sliding; great chemical & temp resistance; softer, so mind wear under load. |

| UHMWPE | 0.15–0.20 | 0.12–0.20 | Low friction + superb abrasion resistance; forgiving with impact and misalignment. |

| POM (Acetal) | 0.20–0.30 | 0.19–0.34 | Stable dimensions; higher PV capacity; great for precise parts (bushings/gears). |

| Nylon (PA6/PA66) | 0.20–0.30 | 0.20–0.31 | Tough and durable; moisture can change size and friction; oil-filled grades slide better. |

Test standard note: Many datasheets cite ASTM D1894 (film/flat friction) or D3702 (thrust washer). If you can, mirror your real counterface and speed.

UHMWPE friction coefficient (low friction + elite wear)

UHMWPE gives you a slippery surface and crazy good abrasion resistance. On conveyors, liners, and rink boards, it reduces sticking and noise. It also shrugs off impacts—handy when a puck or crate hits the wall at an awkward angle.

When UHMWPE fits best

- You need low μ without sacrificing wear and impact.

- You want quieter lines and fewer jams (less stick-slip).

- You’re building dasher boards that must feel fast but not chew up in one season.

Watch-outs

- Continuous temps are moderate compared to PTFE.

- Surface finish matters: a too-rough counterface pushes μ up; a too-polished face can cause stiction at startup.

Nylon (PA) friction behavior (tough, modifiable, but moisture-sensitive)

Nylon sheets is tough and widely available. Base PA6/PA66 sits around 0.20–0.31 in μk. If you go oil-filled or add internal lubricants, you’ll lower drag and improve run-in.

When Nylon fits best

- You need impact strength with decent sliding.

- Parts see intermittent loads and benefit from toughness.

- Cost/availability and machineability are key.

Watch-outs

- Moisture uptake changes dimensions and friction—plan your tolerances.

- In very wet rinks or washdown, PA can swell; consider POM or UHMWPE instead.

POM/Acetal tribology (dimensionally stable + higher PV)

POM gives steady friction, good creep resistance, and higher PV ceilings than PA and UHMWPE in many cases. That’s why engineers use it for bushings, gears, and guides where clearance is tight and speed isn’t tiny. Modified grades (PTFE-filled, silicone-modified) can cut μ while keeping the neat tolerances.

When POM fits best

- You need precision, low creep, and repeatable COF.

- The duty cycle has meaningful speed or pressure (check PV limit).

- You want less sensitivity to moisture vs. Nylon.

Watch-outs

- Base μ is mid-pack; for lowest drag, spec a self-lubricating grade.

- Avoid abrasive dust; add filtration or covers if you can.

PTFE/Teflon friction (the μ king, with trade-offs)

PTFE posts the lowest friction of the group. It’s also chemically inert and tolerates high temperatures. But it’s softer, so under load it can creep and wear faster if you don’t support it well.

When PTFE fits best

- You need the lowest μ possible.

- Media is aggressive, or temperature runs hot.

- Thin liners, bearing cages, seals where friction loss is critical.

Watch-outs

- For structural wear plates, consider PTFE as a surface layer on a tougher backing—or use UHMWPE if impact is real.

Selection guide (match scene → material)

| Scene / pain point | Go-to material | Why it wins | Quick notes |

|---|---|---|---|

| Floor ball dasher boards: fast play + durable wall | UHMWPE | Low μ, elite abrasion, impact forgiving | Texture tune the face; test puck speed and bounce on site. |

| Precision bushings/gears with steady speed | POM | Dimensionally stable, higher PV, predictable μ | Consider PTFE-filled POM for lower drag. |

| Wet or washdown conveyor guides | UHMWPE | Moisture-neutral, low drag | Choose food-grade if needed; avoid over-polished steel. |

| Chemical contact / high temp | PTFE | Lowest μ, inert, heat-tolerant | Support it; don’t expect UHMW-level wear. |

| Tough structural pads with occasional sliding | Nylon | Toughness + modifiable (oil-filled options) | Control humidity; pre-condition parts before machining. |

Real-world tuning: how to get the μ you want (without guessing)

- Counterface roughness (Ra): Slightly smooth but not mirror. Over-polish can cause stick at startup; too rough increases drag.

- Pressure & speed: Check the PV limit for your grade. If your line speeds up, μ and temperature can shift—this are why short trials matter.

- Lubrication: A tiny bit of boundary lube can transform Nylon and POM behavior. UHMWPE often runs dry just fine.

- Edges & chamfers: Break edges on sliders; sharp lips dig in and fake “high friction.”

- Environment: For rinks, ice rink products face ice fog and humidity; for washdown, choose materials that don’t swell.

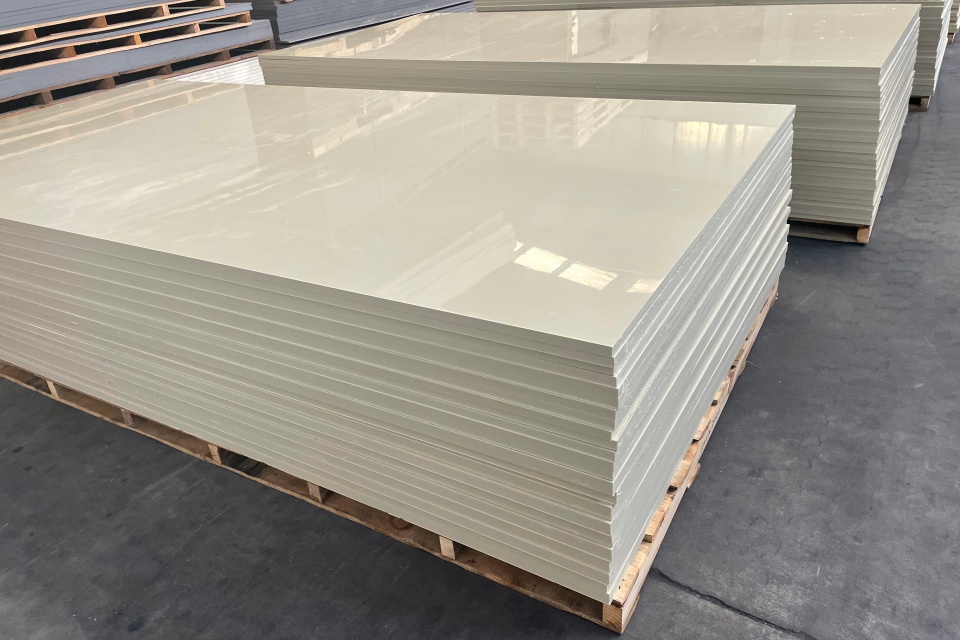

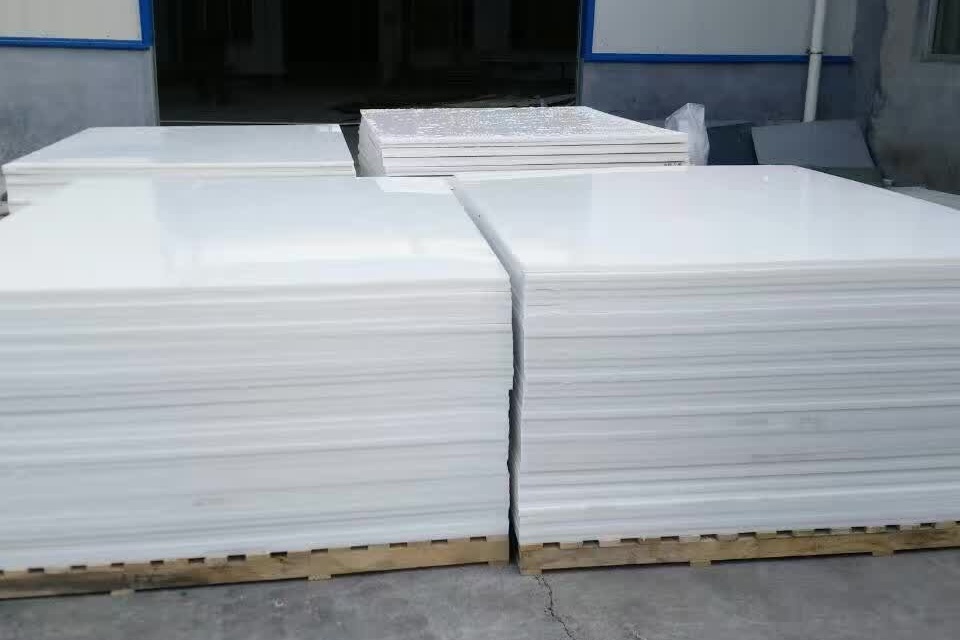

Where Dongxing Rubber fits in (and why it helps you)

At Dongxing Rubber, we manufacture engineering plastic sheets and finished parts under the banner High-Performance Engineering Plastic Products Manufacturer. We live in UHMWPE and HDPE every day—ground protection & road mats, ice rink products, engineering plastic sheets, Nylon sheets, and PP/PE components. We also handle OEM/ODM, bulk runs, and wholesale. If you need panels sized, drilled, grooved, or logo-printed for your rink or facility, we can do it. Samples? We keep lead times short; production follows quick. And yes, real humans reply in under a day.

For rink builders and facility managers, we can spec and supply UHMWPE dasher boards tuned for your puck speed and acoustics. Start here: Floor Ball Dasher Boards.

Mini FAQ

Q: I want the fastest slide possible. Is PTFE always the answer?

If the part doesn’t see much load, yes, PTFE glides best. But for impact and abrasion, UHMWPE is safer. Sometimes we bond a thin PTFE face on a UHMWPE base—best of both.

Q: My Nylon guides squeal after weeks. Why?

Likely moisture changes, small debris, or a too-smooth counterface. Try an oil-filled Nylon, polish-back the steel to a sensible Ra, or switch to POM if tolerances matter more.

Q: POM vs UHMWPE for conveyor flights?

If you need precision and repeatable fit with some speed, POM. If you need abrasion/impact and forgiving slides at lower speed, UHMWPE.

Quick checklist before you order

- Define load (pressure) and line speed; estimate PV.

- Note counterface (steel grade, Ra, hardness).

- Confirm environment (humidity, washdown, temperature, chemicals).

- Decide what fails first if things go wrong: friction, wear, creep, or size change.

- Run a small on-line trial—we’ll cut trial plates or rings so you can compare in days, not months.

Final word

COF isn’t just a number. It’s a system result that shifts with PV, surface, and weather. Start with PTFE for the lowest μ, UHMWPE for low μ + best wear, POM for PV and precision, and Nylon for tough parts that you can tune. If you’d like us to plug in your load/speed and recommend a grade, ping Dongxing Rubber—happy to help, we do this daily.