-

Tian Dong Industrial Park, Decheng District Economic and Technological Development Zone, Dezhou City

Food-Contact Compliance For UHMWPE/HDPE Sheets: A Quick Checklist

You want cutting boards, liners, and chute walls that sail through audits—without back-and-forth, no guesswork. Good. Let’s keep it plain: if your UHMWPE/HDPE sheet meets the right regulations, passes migration testing, and ships with a Declaration of Compliance (DoC), you’re most of the way there. Below is the field guide we use day-to-day at Dongxing Rubber when customers ask for food-contact proof, fast.

Table of Contents

EU Food-Contact: Regulation (EU) 10/2011 (Plastics FCM)

This is the EU’s playbook for plastic materials that touch food.

Overall Migration & Specific Migration (keywords: OML, SML)

- OML (overall migration limit): not more than 10 mg/dm² from the plastic into food under the chosen test conditions.

- SMLs (specific migration limits): set for some monomers/additives.

- UHMWPE/HDPE are usually friendly here.

Food Simulants & Use Conditions (keywords: D2 simulant, OM conditions)

- Testing uses food simulants (like D2 for fatty foods) and standard time/temperature “OM” conditions that match your real use.

- If your sheet sees warm oils, you test with a fatty simulant; if it’s just cold room trim boards, you choose milder conditions.

- The point: test what you actually do (time, temperature, food type), then document it.

DoC + GMP (keywords: Declaration of Compliance, Reg. (EC) 2023/2006)

- You must issue a Declaration of Compliance down the chain.

- Keep a technical file: formulation, migration data, and a NIAS (non-intentionally added substances) risk check.

- Production must follow GMP (Reg. (EC) 2023/2006). That means clean processes, traceability, and records that are audit-ready.

USA: FDA 21 CFR 177.1520 (Polyethylene)

In the U.S., polyethylene (this covers HDPE and UHMWPE) is addressed under 21 CFR 177.1520.

Identity & Extraction (keywords: olefin polymers, extraction limits)

- The rule defines identity/specifications for PE and sets extraction/solubility limits under prescribed solvents and temperatures.

- You choose the correct “item” in the CFR table (sheet vs film, end-use conditions). Then verify your sheet meets those extraction limits.

End-Use Conditions (keywords: use conditions)

- Tight contact at ambient or refrigerated? Usually straightforward.

- Hot-fill or cooking contact? You must match the use condition tables elsewhere in FDA regs. When in doubt, test higher and sleep better.

China: GB 4806.7-2023 (Plastics), GB 9685 (Additives), GB 31604.x (Testing)

China’s framework looks a lot like the EU: a positive list and migration testing rules.

Positive List + Methods (keywords: GB 4806.7, GB 9685, GB 31604)

- GB 4806.7 sets requirements for plastic FCM.

- GB 9685 lists food-contact additives. Your formulation must stay inside it.

- GB 31604 series gives the test methods for migration. Pick conditions that reflect real service.

One-Page Snapshot

| Market/Standard | What It Means For UHMWPE/HDPE Sheets | Key Data Points |

|---|---|---|

| EU – Reg. (EU) 10/2011 + GMP (EC 2023/2006) | Use only authorised monomers/additives; pass overall and any specific migration; follow GMP; issue a DoC. | OML ≤ 10 mg/dm²; SML where applicable; simulants incl. D2 for fatty foods; OM time/temperature to match use. |

| USA – FDA 21 CFR 177.1520 (PE) | PE article must meet identity + extraction specs for the relevant table item (sheet/film and use). | Extractables within CFR limits for the chosen item; use-condition fit (ambient, refrigerated, hot-fill). |

| China – GB 4806.7 / GB 9685 / GB 31604 | Formulation inside positive lists, pass migration by GB 31604 methods, label per GB. | Overall/specific migration per GB; simulant & conditions matched to real use. |

Real-World Scenarios (and how to test/document)

Cutting Boards (butcher, bakery, deli)

- Use: room temp, sometimes warm wash; contact with fatty foods (meat/cheese) and knives (abrasion).

- Testing: choose D2 simulant for fatty contact; time/temperature matching the longest likely soak or contact.

- Docs: DoC + OML + any SML + abrasion note (we often add a surface roughness spec and cleaning guidance).

Conveyor Liners & Chutes (meat processing, veg washing)

- Use: sliding contact, rinse cycles, maybe warm cleaning.

- Testing: conditions covering intermittent warm contact; consider detergent compatibility (not a food law, but a real shop-floor issue).

- Docs: DoC + migration + chemical-resistance note; HACCP line item so QA can file it easily.

Temporary Surfaces Around Prep Zones

- Use: trays, tables, movable guards; short contact, mostly cold.

- Testing: mild conditions, non-fatty simulant unless oil is around.

- Docs: DoC + overall migration summary; keep it lightweight (buyers love quick PDFs).

Quick Compliance Checklist (use this to brief your QA)

- Pick the rulebook first

- EU 10/2011 (+ GMP 2023/2006), or FDA 21 CFR 177.1520, or GB 4806.7 / 9685 / 31604.

- Write it on the order so nobody “guesses” later.

- Lock the formulation

- Confirm resin grade and additives are allowed (EU Union list / GB 9685).

- Note color masterbatch and processing aids; they count too.

- Design the test plan to match the actual use

- Food type (fatty/non-fatty), time, temperature, cleaning.

- Choose simulants (e.g., D2 for fat) and standard OM conditions accordingly.

- Run migration (and any extraction)

- EU: OML and any SML.

- USA: extraction per the correct CFR 177.1520 item.

- China: migration by GB 31604 methods.

- Assess NIAS

- Screen for impurities/reaction products; document why they’re safe for the intended use.

- Keep it short, but real (dont hand-wave).

- Issue the DoC + keep a tidy technical file

- DoC, test reports, NIAS note, GMP records, batch traceability.

- Put a contact email and lot numbers. Auditors love when they can call someone.

- Label and instruct

- Basic use & cleaning guidance (no harsh oxidizers if that matters; temp limits).

- Add a simple “intended use” line so operators dont misuse the sheet.

Manufacturing Notes From the Floor

- Surface finish affects cleaning. A slightly lower Ra can make wash-down faster and reduce micro-hold.

- Thickness tolerance and flatness matter for board stability and machine liners. Less bounce, fewer burrs.

- Traceability is not just a stamp. We log resin lot → sheet lot → shipment. If QA calls, we can backtrace in minutes, not hours.

- Color: Natural (white) is common in food plants; we can supply colors, but remember to re-check the masterbatch listing under the chosen regime.

Where Dongxing Rubber Fits In

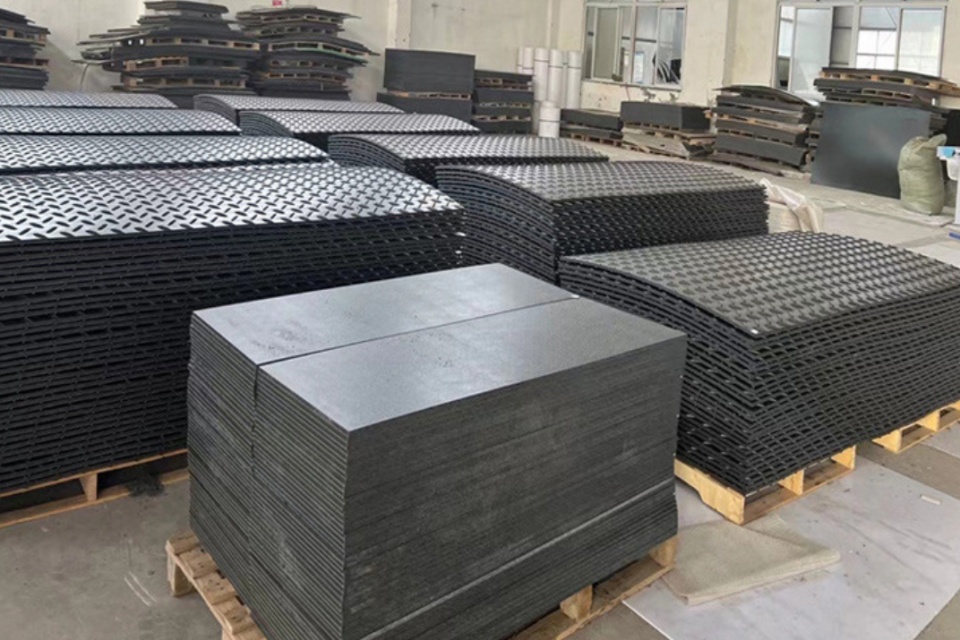

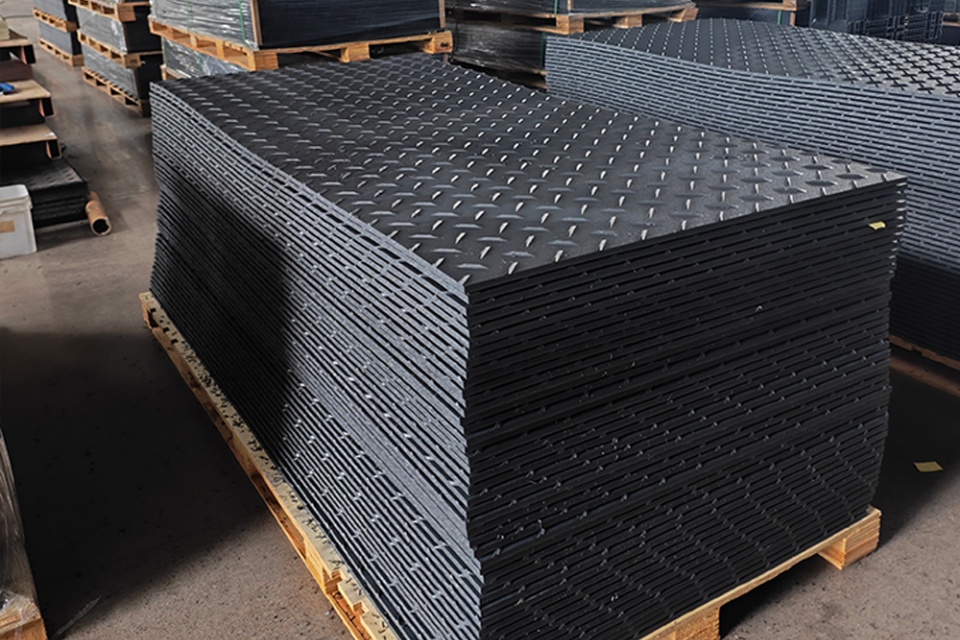

We’re a High-Performance Engineering Plastic Products Manufacturer. We produce UHMWPE & HDPE sheets for food-sector uses—and yes, we also make ground protection & road mats, ice rink boards, and other engineering plastic sheets. For heavy traffic areas around facilities, see our Dura Mats line; it shows our processing depth on PE systems (different scene, same polymer know-how). We do customization, bulk supply, OEM/ODM, and wholesale for distributors. Samples: 3–15 days; production: 3–20; 24-hour response. If you need the DoC pack and migration data bundled with the crate, we prep it before shipment—no worrys.

Mini FAQ (because buyers ask this every week)

- Is UHMWPE “food safe” by default?

Not automatically. The formulation and the tests decide. Base UHMWPE is often fine, but colorants and aids must be checked. - Do you test every lot?

Routine QA + type testing. We keep historical data; if your use changes (hotter, oilier), we re-test to suit. - Can we help with HACCP docs?

Sure. We add a short HACCP alignment note so your QA doesn’t have to rewrite everything.

TL;DR

- Choose your regime first (EU / USA / China).

- Build a realistic migration plan (food type, temp, time).

- Document OML/SML (EU), extraction (USA), or GB migration (China).

- Add NIAS, keep GMP records, issue a DoC.

- If you want it done fast and tidy, Dongxing Rubber will package the sheet + the paperwork so you can pass audits without drama.