-

Tian Dong Industrial Park, Decheng District Economic and Technological Development Zone, Dezhou City

UHMWPE vs HDPE Price–Performance: When Is “Buy Once, Cry Once” Right?

If your equipment lives with grit, impact, and long hours, the UHMWPE vs HDPE choice isn’t just “plastic vs plastic.” It’s uptime vs touch-ups, glide vs grind, and the calm confidence that you won’t be swapping parts right when the crew is finally in rhythm. Here’s a clear, field-tested way to know when the “buy once, cry once” path makes sense.

Table of Contents

UHMWPE vs HDPE: Key Material Properties

UHMWPE brings ultra-long polymer chains that deliver exceptional abrasion resistance, impact absorption, and a naturally low-friction surface. HDPE offers reliable stiffness, chemical resistance, and easy machining at a friendlier entry point. Both are tough in weather and moisture-proof; the split shows up under sliding wear, point load, and relentless cycling.

- Abrasion & friction: UHMWPE’s slicker face sheds scuffing and heat, extending service life in sliding interfaces.

- Impact & fatigue: UHMWPE tolerates repeated hits and vibration better; HDPE is fine for moderate duty and general panels.

- Stiffness & machining: HDPE machines cleanly and stays dimensionally steady for covers, guards, and utility panels.

- Environment: Both resist water and many chemicals across typical outdoor ranges.

If your job leans on lining, gliding, or taking hits, that friction delta is where UHMWPE quietly earns its keep.

Wear, Friction, and Impact: What Really Fails First

Failures rarely start in the middle of a plate; they begin at edges, fasteners, turn-in points, or spots where grit grinds in. UHMWPE’s lower friction reduces stick-slip and gouging, so corners don’t mushroom as fast and surfaces don’t glaze. In impact-rich duty (lift pads, fenders, bin liners), the extra energy absorption shows up as fewer chips and longer intervals between swaps.

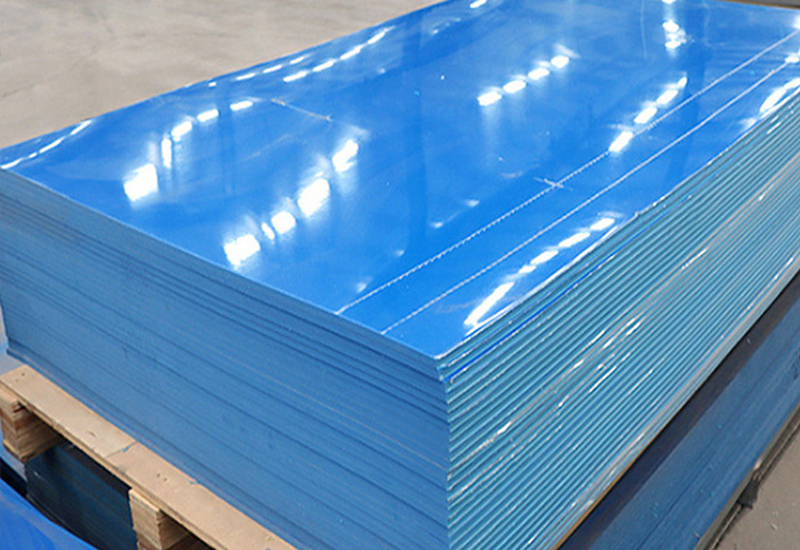

Where HDPE Is the Smart Baseline

Choose HDPE when duty is intermittent, loads are modest, and replacement access is easy. It’s a great fit for utility covers, guards, and general surfaces where you want clean machining and predictable stiffness without over-engineering.

- General panels and guards

- Light-to-moderate sliding with minimal grit

- Fixtures and shields that you can service quickly

When UHMWPE Is the Smarter Long-Run Buy

Pick UHMWPE when abrasion, impact, or access costs dominate the conversation. That’s where “buy once, cry once” pays back in fewer shutdowns, fewer crews dispatched, and cleaner substrates.

- High-cycle sliding/impact (chutes, bins, sills, hoppers)

- Tracked turns and corner shear on work sites

- Heavy lifts, point loads, and marine rub points

- Remote or costly-to-service installations

Field-Proven Formats and Use Cases

Ground logistics and access solutions

Keep equipment moving over soft or sensitive ground with mats designed for land protection and repeated trafficking. For heavier duty or muddy season peaks, step up to engineered variants that shrug off turning abrasion. Explore ground protection options: ground protection road mats and quick-deploy temporary roads: UHMWPE temporary road mats.

Heavy lifts and point-load stability

Outrigger and jack pads see crushing loads, edge gouging, and grit. UHMWPE spreads load and resists creep under cycling, helping cranes and stabilizers stay level across repeated setups. See outrigger solutions: OEM outrigger pads and cribbing systems: heavy-duty UHMWPE cribbing blocks.

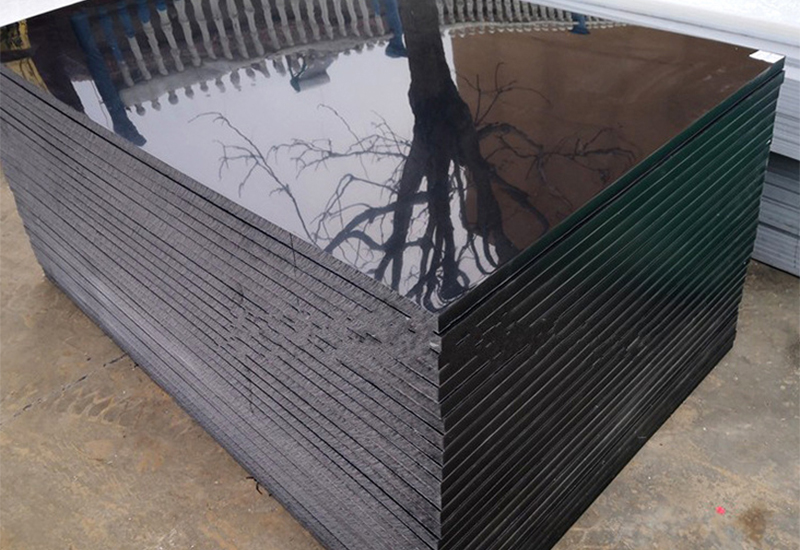

Sliding, lining, and wear control

Liners should keep material moving, not fighting you. UHMWPE’s low friction reduces hang-ups in bins and chutes and slows abrasive thinning. Cut-to-size liner stock: UHMWPE sheets and boards or hybrid floor/track panels: UHMWPE/HDPE heavy-duty floor panels.

Shielding and specialty protection

When the job adds radiation mitigation, borated polyethylene integrates shielding with the same durable base polymer platform. Review borated options: lead-boron polyethylene plates.

Who you’re buying from matters

Beyond resin, success rides on cut quality, edge finishing, and fastener guidance. Learn what’s behind consistent parts and private-label builds: OEM & ODM services and the company’s about page. Start from the homepage to see industries and formats at a glance.

Spec and Design Tips That Pay Back

- Thickness vs span: Size for load paths and turning radii; edge lifting and mid-span flex are early failure triggers.

- Edge conditioning: Chamfers or generous radii reduce peel-ups and chip starts.

- Fastening: Spread load with patterns and washers; avoid tight stress risers at countersinks.

- Surface finish: For liners, smoother faces lower drag; for mats, balance traction with cleanability.

- Rotation plan: Move panels from high-wear corners to low-wear zones before they fail; keep standardized spares.

A Simple Decision Checklist

- Duty cycle: Continuous sliding, turning, or impact? Lean UHMWPE.

- Failure cost: Will swap-outs stall crews or disrupt safety? Favor longer wear life.

- Surface risk: Are you protecting lawns, concrete, hulls, or coatings? Low-friction UHMWPE prevents hidden damage.

- Access reality: Remote or offshore? Avoid re-mobilization with longer-lasting parts.

- Pilot proof: Trial a UHMWPE set in your harshest spot and track wear depth and changeout intervals.

Bottom Line

If your application is modest and serviceable, HDPE is the practical baseline. If abrasion, impact, and downtime are the real budget line items, UHMWPE is the quiet way to “buy once, cry once”—and keep your schedule, gear, and team calm for longer.